A steam boiler is a high-pressure vessel that requires precise management of water, steam, and sediment. To operate safely and efficiently, a series of specialized valves used in boilers must work in harmony. Whether you are performing maintenance or designing a new system, understanding the various boiler valve types is critical for system longevity and personnel safety.

In this guide, we will break down the essential valves on a boiler and explain why each one is indispensable.

Table of Contents

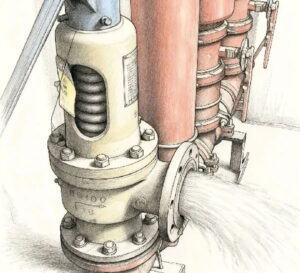

ToggleI. Pressure Protection: The Safety Valve

The most critical valve on a boiler is the Safety Relief Valve.

Function: It acts as the last line of defense. If the internal pressure exceeds the Maximum Allowable Working Pressure (MAWP), this valve pops open to release excess steam.

Key Requirement: Every boiler must have at least one safety valve (often two) that is ASME certified and regularly tested.

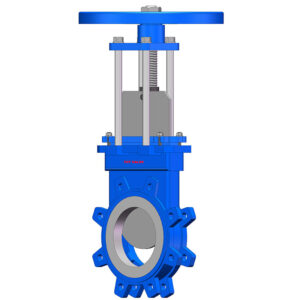

II. Isolation & Control: Steam Stop Valves

When you need to send steam to the process or shut down the boiler for maintenance, you rely on the Main Steam Stop Valve.

Common Types: * Boiler Gate Valve: Ideal for full-on/full-off isolation with minimal pressure drop.

Globe Valve: Used when some degree of flow throttling is required.

Material Matters: For high pressure steam, these valves are usually made from cast steel (WCB) or alloy steel to handle extreme temperatures without warping.

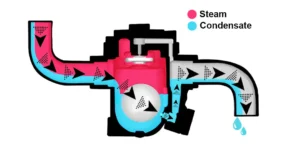

III. Water Level & Purity: Blowdown Valves

The boiler blowdown valve is essential for “cleaning” the boiler while it’s in operation.

The Two Roles:

Surface Blowdown: Removes light impurities and oils floating on the water surface.

Bottom Blowdown: Removes heavy sludge and scale that settles at the bottom.

Design: Unlike a standard boiler water valve, a blowdown valve is built to handle the erosive nature of scale and grit being blasted out at high velocity.

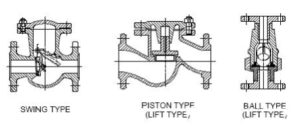

IV. Preventing Backflow: Feedwater Check Valves

To keep the boiler running, water must be constantly pumped in. The Non-Return Valve (NRV) or Check Valve ensures this process is one-way.

Function: It prevents the high-pressure steam inside the boiler from forcing water back into the feed pumps when they are turned off.

V. Maintenance & Drainage: The Boiler Drain Valve

Every system needs a way to empty out.

Function: Located at the lowest point of the system, the boiler drain valve allows for complete evacuation of water for internal inspections or during seasonal shutdowns to prevent freezing and corrosion.

VI. Summary Table: Boiler Valve Types at a Glance

| Valve Name | Primary Function | Common Type |

| Safety Valve | Overpressure Protection | Spring-Loaded Relief |

| Steam Stop Valve | Main Line Isolation | Boiler Gate Valve / Globe |

| Blowdown Valve | Sediment/Sludge Removal | Angle Valve / Ball Valve |

| Check Valve | Prevents Feedwater Backflow | Swing or Lift Check |

| Drain Valve | Complete Emptying | Ball or Gate Valve |

Conclusion

Choosing the right valves for a boiler is about more than just fitting a pipe size; it’s about matching the material, pressure rating (such as PN40 or Class 300), and function to your specific boiler design. From the robust boiler blowdown valve to the high-precision steam flow control valves, each component plays a part in a safe industrial environment.