While main line ball valves manage your entire water supply, a different class of plumbing valve types is critical for localized control: the terminal stop valve. These small valves, typically found under your sinks, behind your toilets, and near appliances, allow you to isolate a single fixture for repair without disrupting water flow to the rest of the house.

This guide explores the essential mechanisms and forms of fixture shut-off valves, helping you identify and choose the right replacement.

Table of Contents

ToggleI. Terminal Valve Types by Operating Mechanism

When examining toilet shut off valve types, the internal mechanism dictates reliability and ease of use.

A. Quarter-Turn Stop Valve (The Modern Choice)

Mechanism: Uses a small internal ball (like a miniature ball valve) that rotates 90°.

Operation: Requires only a quarter-turn of the handle to move from fully open to fully closed.

Advantages: Highly reliable and less prone to failure after long periods of disuse, as the ball shears through minor sediment when operated.

Recommendation: This is the current professional standard due to its dependability and quick shut-off capability.

B. Compression Stop Valve (The Traditional Multi-Turn)

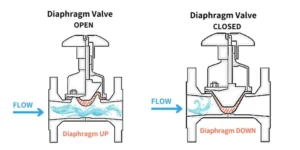

Mechanism: Uses a screw-operated stem to push a rubber washer (or packing) against a seat to seal the flow.

Operation: Requires multiple turns of the handle to close fully.

Disadvantages: The internal washer degrades over time; if left untouched, it often fails to seal properly when turned, leading to leaks or continued flow.

II. Terminal Valve Types by Form Factor (Stop Valve vs. Angle Stop Valve)

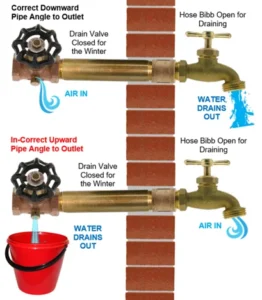

The shape of the valve depends entirely on how the supply pipe enters the fixture area.

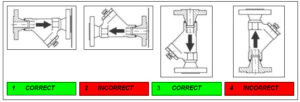

1. Angle Stop Valve

Design: Features a 90° angle between the inlet (from the wall) and the outlet (to the fixture).

Use Case: This is the most common form factor used for toilet shut off valve types and under-sink connections when the supply pipe comes directly out of the wall.

2. Straight Stop Valve

Design: The inlet and outlet are on the same plane (straight through).

Use Case: Used when the supply pipe comes directly up from the floor.

3. Specialty Stops

Dual Outlet Stops: Have one inlet but two separate outlets, often used to feed both a sink faucet and a dishwasher simultaneously.

III. Material and Connection Types

When performing a plumbing valve types replacement, you must consider both the material and the connection method.

A. Material Types

Brass/Chrome-Plated Brass: The industry standard for durability and longevity in potable water lines. Offers the highest reliability.

Plastic Water Valve Types (PVC/PEX): Used primarily in PEX systems. While reliable in PEX installations, they are less common for traditional copper or iron pipe conversions.

B. Connection Types (Mounting Methods)

Compression: Uses a nut and a brass sleeve (ferrule) to squeeze the supply pipe, creating a watertight seal. Requires a clean, straight pipe cut.

Threaded: Screws directly onto a male-threaded pipe stub-out.

Push-Fit (SharkBite-style): Simple DIY installation where the valve is pushed onto the pipe, instantly securing a watertight seal. This is excellent for fast, temporary, or permanent repairs.

IV. DIY Replacement Tip: Upgrading Your Toilet Shut Off Valve

If you have an old, leaking, multi-turn compression stop valve, replacing it is a highly recommended DIY project.

Shut Off Main Water: Always shut off the main water supply to the house first.

Drain Pressure: Open the faucet to relieve pressure in the line.

Disconnect: Disconnect the supply line from the fixture (toilet/sink).

Remove Old Valve: Carefully loosen and remove the old valve.

Install New Quarter-Turn: Install the new quarter-turn angle stop valve using the appropriate connection method (compression, thread, or push-fit).

The Upgrade: Replacing an old multi-turn valve with a reliable quarter-turn valve minimizes the chance of future leaks and ensures you can instantly stop the flow during an emergency.