In the food, beverage, and pharmaceutical industries, a single colony of bacteria can lead to a million-dollar product recall. Unlike industrial valves used in oil or water treatment, Sanitary Valves must meet strict FDA and 3-A standards.

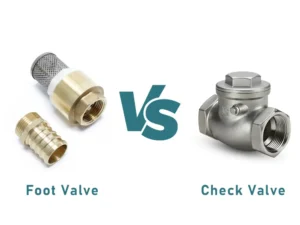

The biggest enemy in these processes is the “Dead Leg”—an area in the valve body where fluid can stagnate, escape the cleaning process, and become a breeding ground for contamination. Here is how to select valves that ensure your process remains sterile and compliant.

Table of Contents

Toggle1. The Surface Finish: More Than Just “Shiny”

In a pharmaceutical valve, the internal surface must be as smooth as glass.

The Standard: We measure this in Ra (Roughness Average). For food grade, Ra < 0.8 µm is standard; for injectables and biotech, we often achieve Ra < 0.4 µm through Electro-polishing.

Why it matters: Even microscopic scratches can trap proteins or bacteria that “CIP” (Clean-in-Place) systems cannot reach.

2. Diaphragm Valves: The Gold Standard for Biotech

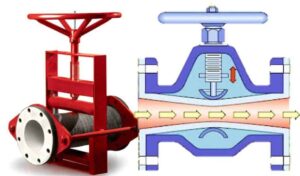

In the pharmaceutical world, the Sanitary Diaphragm Valve is the undisputed leader for high-purity applications.

Zero Dead Leg: The design is “weir-less” or utilizes a specialized body shape that ensures all fluid drains out completely when the valve is open.

Hermetic Sealing: The diaphragm acts as both the seal and the gasket, completely isolating the valve’s operating mechanism from the media. There are no stems or packings to leak or contaminate the product.

Best For: Vaccines, blood products, and sterile injectables.

3. Cavity-Filled Ball Valves: Solving the “Pocket” Problem

A standard ball valve has a “cavity” (the space between the ball and the body) that traps fluid every time the valve cycles. In food production, this trapped milk or juice will spoil.

The Solution: Cavity-Filled Seats. We use specialized PTFE seats that wrap entirely around the ball, filling the void.

The Benefit: This eliminates the “pockets” where bacteria could grow, making the ball valve safe for viscous food products like chocolate, sauces, or jams.

4. Butterfly Valves: The Workhorse of Beverage Lines

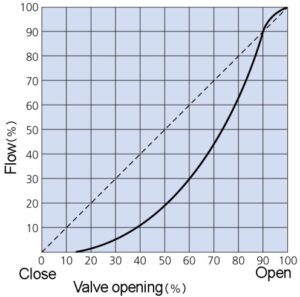

For high-volume, lower-viscosity liquids like beer, soft drinks, or milk, Sanitary Butterfly Valves offer the best ROI.

Easy Tear-down: These valves are designed for quick disassembly without special tools, allowing for manual inspection and cleaning.

FDA Materials: Every seal must be made of FDA-approved EPDM, Silicone, or Viton. We use white or transparent elastomers to ensure no carbon black particles migrate into the food.

5. CIP/SIP Compatibility

Every valve we supply for this industry is designed to withstand:

CIP (Clean-in-Place): High-velocity flow with aggressive caustic sodas and acids.

SIP (Steam-in-Place): Sterilization using saturated steam at 121°C or higher.

Requirement: The elastomers must not lose their elasticity or “bake” onto the metal during these intense heat cycles.

6. Sanitary Valve Selection Guide

| Application | Recommended Valve | Key Benefit |

| High-Purity Biotech | Diaphragm Valve | No dead legs; 100% isolation. |

| Viscous Food (Sauces) | Cavity-Filled Ball Valve | Prevents product entrapment. |

| Beverage / Dairy | Sanitary Butterfly | Cost-effective; Easy to clean. |

| Wort / Mash (Brewing) | Plug Valve (Sanitary) | Reliable with suspended solids. |

Conclusion: Hygiene is an Engineering Choice

In the Food & Pharma sectors, your valve selection is the first line of defense against contamination. By investing in Electro-polished surfaces, Cavity-filled seats, and Zero-Dead-Leg designs, you are protecting your brand’s reputation and your customers’ health.