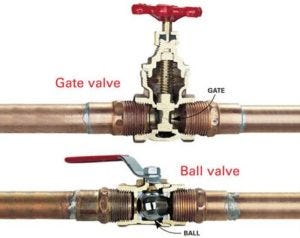

The choice between a full port ball valve and a standard port ball valve (which typically features a reduced port) is a critical decision in fluid system design. While both perform the basic on/off function, their internal geometry dictates differences in cost, flow efficiency, and pressure loss.

Understanding these structural differences is essential for optimizing system performance and controlling energy costs.

Table of Contents

Toggle1. Defining the Difference: Port Geometry

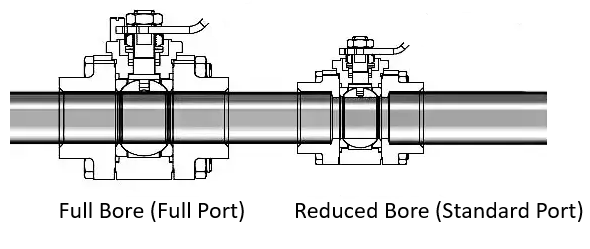

The distinction lies solely in the size of the bore (hole) drilled through the center of the ball.

| Valve Type | Bore Diameter | Flow Characteristics |

| Full Port Ball Valve | The bore diameter is equal to the inner diameter (ID) of the connecting pipeline. | Unrestricted flow, minimal pressure drop, maximum Cv (Flow Coefficient). |

| Standard Port Ball Valve (Reduced Port) | The bore diameter is typically one nominal pipe size smaller than the connecting pipeline. | Restricted flow, noticeable pressure drop, lower Cv. |

2. Advantages of the Full Port Ball Valve

When flow efficiency and maintenance are the top priorities, the full port design is the clear choice.

A. Maximum Flow Efficiency (Low Pressure Loss)

Zero Restriction: Because the flow path matches the pipe size, there is virtually zero head loss across the valve when fully open.

High Cv Value: The flow coefficient (Cv) is the maximum possible, meaning the valve does not act as a bottleneck in the system. This saves energy and optimizes pump efficiency.

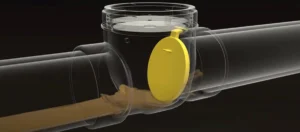

B. Ideal for Pigging Operations

Pipeline Integrity: The full bore allows for the unimpeded passage of PIGs (Pipeline Inspection Gauges or internal cleaning devices). This is essential in oil, gas, and chemical pipelines requiring internal cleaning or inspection.

C. Suitability for Slurries and Viscous Media

Reduced Clogging: The straight, uniform flow path minimizes areas where solids or high-viscosity media (like heavy oils or resins) can accumulate, reducing the risk of clogging.

3. Advantages of the Standard Port Ball Valve (Reduced Port)

When cost and space are the primary constraints, the Standard Port (Reduced Port) design offers practical benefits.

A. Lower Initial Cost and Smaller Size

Smaller Components: Since the internal ball is smaller (to accommodate the reduced bore), the valve body, stem, and actuator can also be downsized. This results in a significantly lower material cost (especially for larger sizes).

Reduced Footprint: The compact size is advantageous in installations where space is severely limited.

B. Lower Operating Torque

Smaller Ball: A smaller ball requires a smaller seating area and less force to turn. This reduces the size (and cost) of the necessary actuator, lowering the overall automation expense.

C. Commonly Available

The Standard Port is the most commonly manufactured and stocked valve configuration across the industry, often leading to better availability and faster delivery times.

4. Direct Comparison: Key Engineering Metrics

Engineers must weigh these financial and performance trade-offs during system design.

| Metric | Full Port Ball Valve | Standard Port Ball Valve (Reduced) |

| Flow Coefficient (Cv) | Highest (Cv ≈ 100% of pipe) | Lower (Cv ≈ 50% of pipe) |

| Pressure Loss | Negligible / Near Zero | Noticeable / Significant |

| Initial Cost | Higher (Requires a larger ball) | Lower (Requires less material) |

| Actuation Torque | Higher | Lower |

| Maintenance (Pigging) | Essential for Pigging Systems | Unsuitable for Pigging Systems |

5. Selection Guide: When to Choose Which

Choose the Full Port Valve When:

High Flow Efficiency is Critical: In long-distance pipelines where even minor pressure loss results in high pumping energy costs.

Handling Viscous Media: To prevent clogging and ensure smooth flow of slurries, resins, or high-viscosity fluids.

Pipeline Inspection or Cleaning is Required (Pigging): Ensures the passage of tools without obstruction.

Choose the Standard Port Valve (Reduced Port) When:

Cost is the Primary Driver: For non-critical utility lines where slight pressure loss is acceptable and budget is tight.

Space and Weight Constraints Exist: The smaller, lighter structure simplifies installation in tight configurations.

The Valve is Used for Throttling: If the valve is not going to be fully open anyway (i.e., used to regulate flow), the restricted bore is less of a concern.

The final decision between a full port ball valve and a standard port (reduced port) ball valve must always be based on the balance between long-term operational efficiency and initial procurement costs.