Table of Contents

ToggleThe Bonnet’s Role in Specific Valve Types

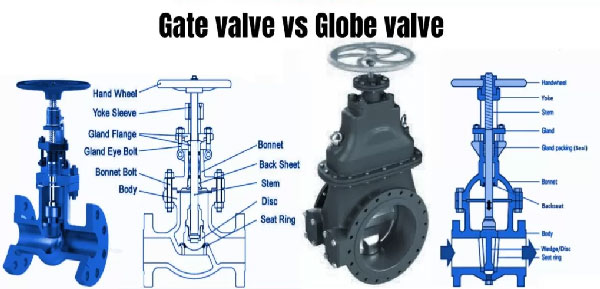

The valve bonnet, as the cap of the valve body, is universal in function (to contain pressure and house the stem assembly). However, its specific design and maintenance characteristics vary significantly between different valve types. The design of the internal mechanism dictates the structure of the bonnet of a valve.

This guide contrasts the bonnet found on the Gate Valve (isolation service) and the Globe Valve (throttling service), highlighting how the core valve function influences the final bonnet design.

I. The Gate Valve Bonnet: Designed for Isolation and Maintenance

The Gate Valve Bonnet is typically robust and straightforward, designed to allow the rising stem necessary for the ON/OFF isolation function.

A. Structure and Operation

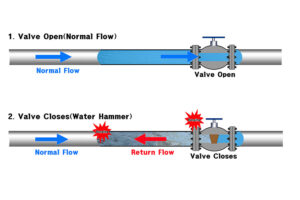

Mechanism Link: Gate valves use a wedge or plate (gate) that moves perpendicular to the flow path. This movement requires a long stem travel, which must be fully sealed by the bonnet assembly.

Common Design: The most common form is the bolted bonnet gate valve. This is preferred because Gate Valves are often used in simple ON/OFF scenarios and the bolted bonnet offers easy access for replacing the packing or the internal gate assembly during scheduled downtime.

Sealing Focus: The main design consideration for the bonnet gate valve is ensuring the integrity of the stem seal, especially since the stem moves frequently during operation.

B. Maintenance Consideration

When maintenance is required, the entire gate and stem assembly often lifts out through the bonnet opening. This makes the gate valve bonnet a crucial maintenance port.

II. The Globe Valve Bonnet: Influenced by Flow Control Geometry

The Globe Valve Bonnet is closely linked to the valve’s ability to throttle and regulate flow, distinguishing it structurally from the Gate Valve design.

A. Structure and Operation

Mechanism Link: Globe Valves use a disc that moves vertically toward or away from a seat located in the center of the valve. The body often features a Z–Pattern or Y–Pattern flow path, which influences the bonnet’s orientation.

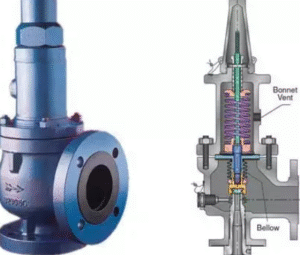

Control Valve Bonnet: In high-performance applications, the Globe Valve is often used as a control valve. The control valve bonnet must be meticulously designed to provide precise stem guiding and ensure minimal friction, which is vital for accurate throttling by the actuator.

Bonnet Globe Valve: The valve requires precise alignment between the stem and the seat. Therefore, the bonnet is integral to maintaining the required concentricity for both sealing and throttling performance.

B. Bonnet Design Variation

Due to the internal geometry, Globe Valve bonnets may sometimes be angled (YPattern or Angle Pattern) to improve flow characteristics and reduce pressure drop, a variation rarely seen in the Gate Valve structure.

III. Bonnet Maintenance and Design Comparison

The differences between the Gate Valve and Globe Valve bonnets manifest most clearly during routine maintenance.

| Feature | Gate Valve Bonnet | Globe Valve Bonnet |

| Primary Function | Housing for isolation stem and packing. | Housing for throttling stem and guiding system. |

| Stem Movement | Requires large, full-stroke motion. | Requires relatively shorter, precise throttling motion. |

| Internal Access | Excellent (the gate/wedge assembly can often be fully removed through the opening). | Good (the disc can be accessed, but the internal seat/bridge remains fixed). |

| Sealing Risk | High risk of external stem leakage due to frequent cycling and long travel. | High risk of internal seat leakage due to wear from throttling. |

| Common Type | Bolted Bonnet (for maintenance ease). | Can be Bolted or Pressure Seal (for high-pressure control). |

Conclusion: Function Dictates Form

While the bonnet of a gate valve is structurally designed to accommodate a rising isolation stem, the bonnet globe valve design must prioritize precise stem alignment for throttling. Both designs rely on the sealing principles discussed in our earlier guide (see: The Valve Bonnet Explained).

Understanding these structural requirements ensures you select the valve with the correct bonnet type for your specific operational needs, whether it’s simple isolation or continuous flow regulation.