When it comes to underground water shut-off valve types, the debate usually boils down to two heavyweights: the Gate Valve and the Ball Valve. While your indoor plumbing might rely heavily on ball valves, the rules change once you go below the frost line.

In this guide, we specifically look at how these valves perform in underground main lines, focusing on durability, flow capacity, and why the “classic” gate valve still dominates municipal infrastructure.

Table of Contents

Toggle1. What is a Gate Valve? (The Industrial Standard)

With over 14,000 monthly searches, the gate valve (sometimes misspelled as gateway valve) remains the most common valve for large-scale water distribution.

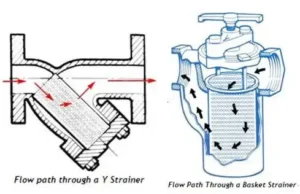

How it works: It uses a wedge-shaped “gate” that slides up and down. When fully open, the gate retreats completely into the valve bonnet.

The Underground Advantage: It offers a straight-through flow with zero resistance. This is critical for underground water valves where maintaining high pressure over long distances is essential.

2. Gate Valve vs. Ball Valve: The Underground Showdown

While our [Isolation Valve Guide] covers general indoor use, here is how they compare in a buried environment:

| Feature | Gate Valve (The Heavyweight) | Ball Valve (The Quick-Act) |

| Water Hammer | Low Risk. Slow closing prevents pressure spikes in long main lines. | High Risk. Fast 90-degree turn can cause “water hammer” and burst old underground pipes. |

| Flow Restriction | Zero. The “Full Port” design allows for maximum GPM. | Minimal. But slightly more turbulence than a gate valve. |

| Durability | Excellent for permanent, fully-open positions (Main Lines). | Better for frequent on/off use (Irrigation zones). |

| Space | Needs more vertical space for the bonnet (requires a deeper valve box). | Compact; fits easily in shallow sprinkler boxes. |

3. Why Gate Valves Rule the Main Water Line

If you are researching main water shut off valve types, you’ll notice that city mains almost exclusively use gate valves.

Slow Shut-off: Underground pipes are under immense pressure. Closing a 2-inch or 4-inch line instantly (as a ball valve does) can send a shockwave that shatters pipe joints. The multi-turn operation of a gate valve is a built-in safety feature.

Unrestricted Cleaning: If you ever need to “pig” (clean) the pipes or run a camera through the line, a gate valve provides a clear, unobstructed path.

4. When Should You Choose a Ball Valve Underground?

Despite the benefits of gate valves, underground ball valves are winning in specific scenarios:

Irrigation Manifolds: For your sprinkler system, where you may need to shut off sections frequently for winterization, the quick 90-degree turn is more convenient.

Corrosion Resistance: High-quality stainless steel or brass ball valves are less likely to “seize” compared to old-fashioned iron gate valves if they aren’t exercised regularly.

5. Identifying Your Valve: “Gateway” or Gate?

A common point of confusion is the term gateway valve. In the plumbing world, this is almost always a misspelling of gate valve. If you are searching for a replacement, ensure you look for:

Rising Stem: The handle moves up as you open it (common in industrial settings).

Non-Rising Stem (NRS): The handle stays at the same height. NRS valves are the standard for underground use because they fit inside compact underground valve boxes.

6. Maintenance Tip: “Exercise” Your Underground Valves

The biggest enemy of a buried underground water valve is sediment buildup.

The Rule: Once a year, use your valve key to turn the valve halfway off and then back on. This “breaks” any mineral deposits on the gate or ball, ensuring it will actually work when a real emergency happens.