Steam is the lifeblood of a power plant, but it is also a volatile energy source. In a high-pressure steam environment (often exceeding 500°C and 100 bar), a minor valve leak can escalate into a catastrophic “steam cut” or a complete plant shutdown costing millions.

Selecting valves for steam service is not just about pressure ratings; it’s about managing thermal expansion, high-velocity erosion, and long-term material integrity. Here is how we engineer valves to survive the most demanding steam loops in the power industry.

Table of Contents

Toggle1. The Material Challenge: Why Carbon Steel is Not Enough

Standard carbon steel loses its strength at temperatures above 400°C. In high-pressure steam, the metal can undergo Creep—a slow, permanent deformation under stress.

The Solution: For HP Steam, we utilize Alloy Steels such as ASTM A217 Grade WC6 or WC9 (Chrome-Moly). These alloys are specifically designed to maintain mechanical strength and resist oxidation at extreme temperatures.

The Expert Choice: For ultra-supercritical plants, we move to F91 or F92 high-grade alloys to ensure 20-year service lives.

2. Preventing “Stem Binding” from Thermal Expansion

A valve that works perfectly in a warehouse can seize up (jam) once it reaches 500°C.

The Physics: The valve stem and the body expand at different rates. If the tolerances are too tight, the valve won’t open when it’s hot.

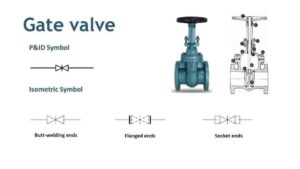

The Solution: We utilize Flexible Wedges in our gate valves and precision-machined stem clearances. Additionally, high-quality steam valves must feature Stellite-faced seating surfaces (Cobalt-based alloy) to prevent “galling” (metal-to-metal welding) during thermal cycles.

3. The “Pressure Seal” Bonnet: Safety Under Pressure

In traditional valves, higher pressure pushes the bonnet away from the seal, increasing the risk of a blowout. In power plants, we use the Pressure Seal Bonnet design.

How it works: The internal system pressure actually forces the bonnet tighter against the gasket.

The Benefit: The higher the pressure, the tighter the seal. This design is significantly lighter and safer for high-pressure service than traditional bolted bonnets.

4. Parallel Slide Gate Valves vs. Wedge Gates

In steam lines, Thermal Binding is a major risk for wedge-style gate valves. If you close a valve while it’s hot, and the system cools down, the wedge can get “trapped” as the body contracts.

The Alternative: Parallel Slide Gate Valves.

Why it’s better for steam: They use two independent discs that are pushed against the seats by system pressure. Since there is no mechanical wedging action, they cannot get stuck due to temperature changes, making them the preferred choice for Main Steam Isolation.

5. Critical Maintenance: The Role of the “Stop Check”

One of the most vital valves in a boiler system is the Bolted Bonnet Stop Check Valve.

Two-in-One: It acts as a globe valve (for isolation) and a check valve (to prevent backflow to the boiler) in a single body.

Safety First: This prevents high-pressure steam from a running boiler from entering a “dead” boiler where maintenance crews might be working.

6. Power Plant Steam Valve Selection Matrix

| Valve Type | Primary Application | Critical Feature |

| Pressure Seal Gate | Main Steam Isolation | Self-tightening seal; High safety. |

| Globe Valve | Steam Throttling / Venting | Hardened Stellite trim for erosion resistance. |

| Parallel Slide Gate | Main Steam Lines | Prevents “Thermal Binding.” |

| Stop Check Valve | Boiler Feedwater / Outlet | Integrated backflow protection. |

Conclusion: Engineering for the 1% Failure Risk

In a power plant, “99% reliable” is a failure. Steam valves must be built for the absolute worst-case scenario.7 By combining Chrome-Moly alloys, Pressure Seal technology, and Stellite-faced internals, we provide valves that don’t just hold the pressure—they ensure the safety of your personnel and the stability of your grid.