A leaking solenoid valve is one of the most common issues in irrigation, pneumatic, or industrial fluid control systems. The leak is usually a sign that the valve’s ability to seal or cycle is compromised. Repairing it is often much simpler and cheaper than replacing the entire valve, provided the main body casing is intact.

If you’re asking, “How to fix a leaking solenoid valve?,” the solution depends entirely on whether the leak is external (water escaping from the valve body or solenoid cap) or internal (water constantly flowing through the valve to the downstream piping).

Table of Contents

Toggle🔍 Step 1: Diagnose the Type of Leak

A. Internal Leak (Constant Flow/Drip)

The valve appears dry, but the fluid (water) is constantly running into the zone or system when it should be off.

Cause: The valve fails to seal. This is typically due to debris lodged on the valve seat or a damaged/stiff diaphragm.

B. External Leak (Visible Leakage)

Fluid is visibly escaping from the top, sides, or connections of the valve.

Cause: A failure of the external seals—the bonnet gasket, O-rings, or the solenoid cap seal.

⚠️ Step 🔌 Step 2: Safety and Depressurization

Before opening any pressurized valve, follow these critical safety steps:

Shut Off Main Supply: Locate the main isolation valve for the system (e.g., the primary stopcock or supply valve) and turn the water or fluid supply OFF completely.

Relieve Pressure: Briefly open a valve further downstream or use the manual bleed screw on the affected valve to release any residual pressure trapped in the line.

🔧 Step 3: Fixing an Internal Leak (Debris or Diaphragm Issue)

This procedure focuses on cleaning or replacing the valve’s core sealing component.

A. Clean the Seat and Diaphragm (Most Common Fix)

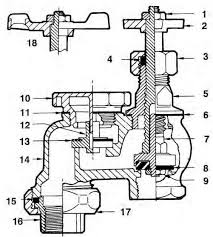

Remove the Solenoid: Gently unscrew the electrical solenoid (the coil/plunger unit). Set it aside, ensuring the connected wires remain undamaged.

Remove the Bonnet: Unscrew the bolts or collar holding the bonnet (the top plastic or metal piece) onto the main valve body.

Inspect the Diaphragm: Carefully lift out the rubber diaphragm . Note its exact orientation for reassembly.

Clean: Thoroughly clean the diaphragm, focusing on the edges and the small weep holes. Crucially, clean the valve seat (the area inside the valve body where the diaphragm sits) to remove any grit, sand, or debris. Use a soft cloth—never use sharp tools that could scratch the seat.

Check Condition: Inspect the diaphragm for stiffness, tears, or warping. If the rubber is brittle or cracked, it must be replaced.

B. Replace the Diaphragm

If cleaning doesn’t work, purchase a genuine diaphragm and repair kit specifically for your valve model (e.g., Rain Bird, Hunter, Asco). Install the new diaphragm, ensuring it is perfectly centered on the valve seat.

🔩 Step 4: Fixing an External Leak (Seal Failure)

These leaks involve compromised seals around the valve housing.

A. Leak from the Bonnet (Top to Body)

Cause: Failure of the large bonnet gasket or simply loose screws.

Action: If possible, try gently tightening the bonnet screws in a crisscross pattern. If the leak persists, the bonnet gasket or O-ring needs replacement.

B. Leak from the Solenoid Cap

Cause: The O-ring or seal where the solenoid screws into the bonnet has degraded.

Action: Unscrew the solenoid (with power off), check the O-ring, and replace it if it is cracked or flattened. Ensure the solenoid is screwed back in firmly but do not overtighten, which can damage the seal groove.

✅ Step 5: Reassembly and Testing

Reassemble: Carefully replace the bonnet and screws, tightening them evenly and securely to ensure uniform compression of the gasket. Reinstall the solenoid.

Restore Pressure: Slowly turn the main supply valve back ON. Listen and watch for leaks at the bonnet and fittings.

Functional Test: Run the circuit manually from the controller. Verify the valve opens fully and, most importantly, shuts off completely and holds the pressure without flowing when the cycle ends.

By systematically addressing the failed component, you can reliably fix a leaking solenoid valve and restore the efficiency of your fluid system.