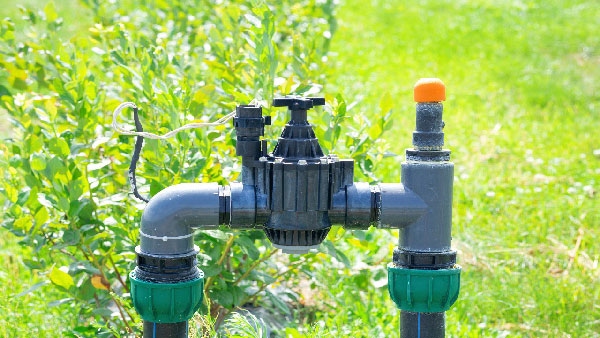

A leaky irrigation valve is the single largest contributor to water waste and high utility bills in a home or commercial landscape system. Whether the leak manifests as water constantly running into a zone (internal leak) or pooling around the valve box (external leak), the issue signals a compromised seal that needs immediate attention.

If you are searching for “how to fix a leaky irrigation valve,” this comprehensive guide will help you quickly diagnose the source of the leak and perform the necessary repair, restoring your system’s efficiency.

Table of Contents

Toggle🔍 Step 1: Diagnose the Leak Type

Identifying the source of the leak dictates the repair strategy.

A. Internal Leak (Phantom Flow)

Symptom: The valve itself appears dry, but the sprinklers in that zone are constantly spraying, dripping, or the ground is saturated, even when the controller is OFF.

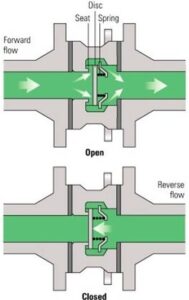

Diagnosis: The valve is failing to seal the main flow port. The cause is almost always debris lodged on the seat or a damaged/worn diaphragm.

B. External Leak (Visible Leakage)

Symptom: Water is visibly squirting or dripping from the seams, screws, or solenoid cap of the valve inside the valve box.

Diagnosis: A failure of the external seals—the bonnet gasket, O-rings, or a cracked valve housing.

🛑 Step 2: Safety, Shut-Off, and Access

Before any repair, ensure the system is safe and clear of pressure.

Shut Off Main Water Supply: Locate the main isolation valve for the irrigation system (or the property’s main water shut-off) and turn the water OFF completely.

Relieve Pressure: Briefly turn on the affected zone via the controller or manually open the bleed screw on the faulty valve. This releases trapped pressure and makes the valve safe to open.

Access: Remove the valve box lid and carefully clear away all mud and soil from the faulty valve, exposing the entire valve body and its connections.

🛠️ Step 3: Fixing an Internal Leak (The Common Culprit)

Internal leaks are the most frequent issue and are usually fixed by cleaning the internal components.

A. Disassemble and Inspect the Diaphragm

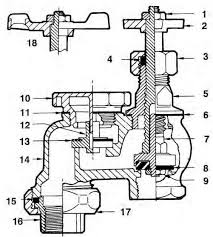

Remove the Solenoid: Gently unscrew the electrical solenoid (the coil unit). Set it aside, keeping the wires attached if possible.

Remove the Bonnet: Unscrew the bolts or collar holding the valve bonnet (the top piece) onto the main valve body.

Lift and Note Orientation: Carefully lift out the rubber diaphragm. It is critical to note its exact placement and orientation, as improper reinstallation causes immediate leaks.

Clean the Seat: Use a clean, soft cloth to meticulously wipe the valve seat inside the body. This is the most critical step. Any tiny particle of sand or debris here will prevent the new or old diaphragm from sealing.

Inspect the Diaphragm: Check the diaphragm for tears, stiffness, or warping. Look closely at the small weep holes. If the rubber is compromised, you must replace it.

B. Reassembly and Test

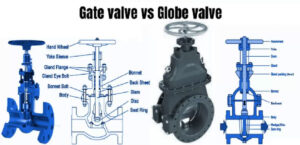

If replacing the diaphragm, use a genuine valve repair kit specific to your valve brand (e.g., Hunter, Rain Bird).

Reinstall the diaphragm correctly, replace the bonnet, and tighten the screws evenly and snugly (do not overtighten).

Slowly turn the water back on to test the seal.

🔩 Step 4: Fixing an External Leak (The Seal Failure)

External leaks are often solved with simple replacements of seals or O-rings.

A. Leak from the Bonnet Seam

Fix: If water leaks from the seam between the top bonnet and the body, the bonnet gasket is likely the culprit. Replace the gasket with a new one from a repair kit. Ensure the bonnet screws are tightened uniformly in a crisscross pattern to achieve an even seal compression.

B. Leak from the Solenoid Threads

Fix: If the leak originates where the solenoid screws into the body, the solenoid O-ring or seal has failed. Unscrew the solenoid, replace the small O-ring, and screw the solenoid back in firmly.

C. Leak from the Manual Bleed Screw

Fix: Ensure the bleed screw is fully closed. If it continues to leak, the small cap O-ring or washer within the bleed screw assembly needs replacement.

💔 When to Fully Replace the Valve

You have completed the essential steps of fixing a leaky irrigation valve. However, a full replacement is necessary if:

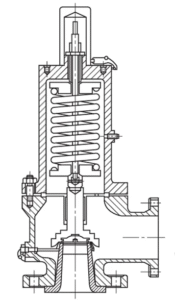

Cracked Housing: The main plastic or metal valve body is cracked (often from freeze damage or impact). This requires cutting the valve out of the line.

Stripped Threads: The threads for the bonnet screws or solenoid are stripped, preventing a secure seal.

Obsolete Parts: You cannot source a diaphragm or gasket kit because the valve is too old and discontinued.

By systematically isolating and repairing the internal sealing mechanism, you can quickly and cost-effectively fix leaking irrigation valve issues and save valuable water resources.