A leaky sprinkler valve is more than just an annoyance; it’s a source of wasted water, increased utility bills, and potentially damaging saturation near your foundation. When the valve—the gatekeeper of your irrigation zone—fails to close completely, it often signals an internal issue that requires straightforward but precise intervention.

The good news is that most common sprinkler valve leaks can be diagnosed and repaired by a homeowner or groundskeeper with basic tools. Understanding how to fix a leaky sprinkler valve involves pinpointing the leak’s origin: is it leaking externally from the top, or is it leaking internally, causing water to constantly flow to that zone?

Table of Contents

Toggle🔍 Step 1: Diagnose the Type of Leak

Before reaching for your tools, you must determine where the water is escaping.

A. External Leak (Water leaking from the top or sides of the valve)

This usually indicates a failure of the diaphragm, bonnet seal, or solenoid seals. The water is escaping from the housing itself.

B. Internal Leak (Water constantly runs to the zone)

This is the “phantom flow” leak. The valve appears dry on the outside, but the sprinklers for that zone are constantly dripping or running, even when the system is off. This means the valve is failing to seal the flow port—usually due to debris or a damaged diaphragm.

🛠️ Step 2: Safety First – Shut Off the Water

Crucial for any plumbing repair:

Locate the Main Shut-off: Find the main isolation valve for your irrigation system (often a ball valve or a stop and waste valve) and turn the water supply OFF.

Bleed the Pressure: Briefly turn on any zone using the controller, or manually bleed the pressure from the faulty valve itself (usually by turning a small solenoid lever or bleed screw). This releases any trapped pressure, making the valve safer and easier to open.

🩺 Step 3: Fixing an Internal Leak (Phantom Flow)

Internal leaks are the most common issue and are usually caused by tiny pieces of grit or sediment preventing the diaphragm from seating correctly.

A. Clean the Diaphragm and Seat

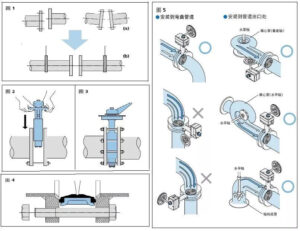

Remove the Bonnet: Unscrew the solenoid (the electrical component) and carefully unscrew the bolts or collar holding the valve bonnet (the top piece) onto the main body.

Inspect the Diaphragm: Gently lift out the rubber diaphragm (the flexible disc). Note its orientation!

Clean: Thoroughly wipe the diaphragm clean with a soft cloth. Crucially, clean the seat (the area inside the valve body where the diaphragm seals) to remove any sand, silt, or debris.

Check for Damage: Inspect the diaphragm for tears, wrinkles, or stiffness. If the rubber is compromised, you will need to replace the diaphragm with a genuine part specific to your valve model.

Reassemble: Carefully place the diaphragm back into position, ensuring it seats perfectly, replace the bonnet, and tighten the screws evenly.

B. Check the Bleed Screw / Solenoid

If debris is not the issue, the leak might be caused by an obstruction in the tiny internal ports or the bleed screw not being fully closed.

Make sure the manual bleed screw is finger-tight (do not overtighten).

Remove and inspect the solenoid, cleaning any debris from the small filter or opening where the solenoid attaches.

🔩 Step 4: Fixing an External Leak (Top and Side Leaks)

External leaks are usually easier to spot and involve compromised seals.

A. Leaks from the Bonnet (Between the top and body)

If the screws holding the bonnet are slightly loose, carefully tighten them evenly (do not strip the threads).

If tightening doesn’t stop the leak, the main bonnet gasket or O-ring is likely damaged and needs replacement. This is usually included in a standard valve repair kit.

B. Leaks from the Solenoid

If water seeps from where the solenoid screws into the bonnet, remove the solenoid and inspect its O-ring or seal. Replace it if it shows cracks or deformation.

Ensure the solenoid is screwed in firmly, but again, do not overtighten, which can damage the delicate seals.

💡 Expert Tip: Prevent Future Leaks

The best way to avoid constant valve repairs is prevention.

Install a Filter: If your water source is a well, pond, or is known to carry significant sediment (common in regions like the Southwest US), install a proper mainline filter upstream of the entire valve manifold. This simple step drastically reduces debris reaching the sensitive diaphragm seals.

Use the Right Parts: Always use manufacturer-specific repair kits. Generic diaphragms often don’t seat correctly, leading to recurring internal leaks.

Test and Maintain: Cycle your valves manually once a season. This prevents the seals from sticking and helps flush out minor debris before it causes a major failure.

By systematically cleaning or replacing the compromised components, you can efficiently and effectively fix a leaky sprinkler valve and restore peak efficiency to your irrigation system.