In modern industrial refrigeration architecture, the Solenoid Valve (or SOV) serves as the “hands and feet” of remote automation. Whether managing the simple start-stop of a liquid line or orchestrating complex four-way hot gas defrost cycles, the response speed and sealing reliability of a solenoid valve directly impact the energy efficiency and safety of the entire plant.

For large-scale cold storage facilities or rapid-freezing food lines, selecting a solenoid valve capable of withstanding high pressure differentials while maintaining coil longevity is critical for preventing non-scheduled downtime.

Table of Contents

Toggle1. Industrial-Grade SOV vs. Commercial Solenoids: The Key Differences

When searching for “solenoid valves,” the market is flooded with light-duty consumer products. In industrial refrigeration—particularly for Ammonia (R717) or High-Pressure CO2 (R744) systems—an SOV (Solenoid Operated Valve) must meet significantly higher specifications:

High Maximum Opening Pressure Differential (MOPD): During the initiation of a defrost cycle, valves often face massive pressure gaps. High-performance industrial SOVs must open reliably under these loads to prevent coil burnout.

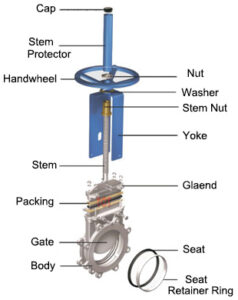

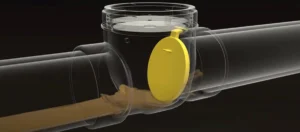

Pilot-Operated Construction: For large-bore piping (DN50 and above), pilot-operated designs are standard. These utilize the media’s own pressure to assist the opening stroke, allowing for high flow rates with minimal electrical power consumption.

Corrosion Resistance: Coils must be rated for IP65 or IP67 protection to withstand the heavy condensation and chemical exposure typical in industrial cooling environments.

2. Critical Applications in the Refrigeration Cycle

Solenoid valves perform several high-precision tasks within a system. Here are the three most common industrial use cases:

A. Liquid Line Cut-off (Pump-down Cycle)

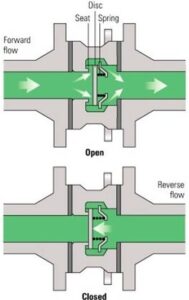

To prevent “liquid slugging” in the compressor during downtime, an SOV is installed between the condenser and the expansion valve. When the target temperature is reached, the SOV closes first; the compressor continues to run until the evaporator is cleared of liquid, ensuring a safe start-up for the next cycle.

B. Hot Gas Defrost Control

Automated defrosting is essential for maintaining evaporator efficiency in industrial freezers. The SOV is responsible for diverting high-temperature, high-pressure gas from the compressor discharge into the evaporator. This requires the valve to have exceptional thermal shock resistance, as it rapidly switches from cryogenic to high-heat states.

C. Suction Line Isolation

In multi-temperature systems, solenoid valves isolate different evaporator branches, ensuring that pressure distribution across the plant aligns with specific process requirements.

3. Engineering Details: Ensuring Valve Longevity

Industrial maintenance is expensive. When selecting an SOV, look for these specific engineering features to reduce the “Total Cost of Ownership”:

Manual Override Function: In the event of a power failure or during system commissioning, a manual override lever allows for forced opening, ensuring production continuity.

PTFE Valve Seat Sealing: Compared to standard elastomers, PTFE offers superior resistance to refrigeration oils and remains resilient at extremely low temperatures, preventing “sticking” or bypass leakage.

Encapsulated Coils: High-quality valves feature composite-encapsulated coils that maintain low temperature rise even during continuous duty, significantly extending the life of the solenoid.

4. Best Practices: Orientation and Filtration

To ensure the reliability of your automated control loop, follow these two critical rules:

Mandatory Filtration: Solenoid valves are highly sensitive to debris. A suction or liquid line filter must be installed upstream to prevent welding slag or pipe scale from clogging the pilot orifice.

Mounting Orientation: Most industrial SOVs must be installed with the coil in the upright vertical position. Installing a valve upside down or on its side can lead to gravity interference with the pilot plunger, preventing the valve from resetting properly.

Conclusion: The Foundation of Automated Cooling

From simple isolation valves to sophisticated Solenoid Operated Valves (SOV), the evolution of industrial refrigeration is driven by “Precision” and “Safety.” Correctly configuring your solenoid valves and their associated accessories not only reduces manual labor but also provides significant energy savings through optimized defrost frequency control.