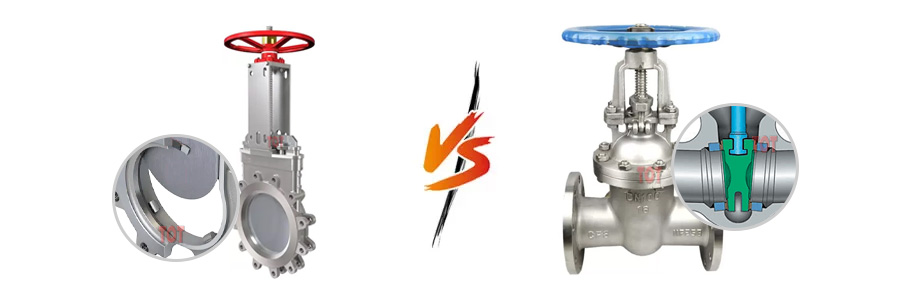

At first glance, a knife gate valve and a standard gate valve look similar. Both are linear-motion valves used to start or stop flow. However, if you try to use a standard gate valve in a mining slurry line or a sewage plant, it will likely jam and fail within weeks.

The difference isn’t just in the name; it’s in the bottom of the valve body. This guide explains the critical design differences and why the “Knife” is mandatory for certain media.

Table of Contents

Toggle1. The Design: The “Pocket” vs. The “Blade”

This is the most critical technical distinction that every engineer should know:

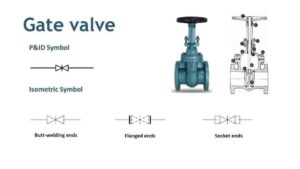

Standard Gate Valve (The Wedge Design)

A standard gate valve uses a heavy wedge that sits in a recessed “pocket” at the bottom of the valve body to achieve a seal.

The Problem: In slurry or wastewater, this pocket acts as a trap. Debris, sand, and fibers settle in the pocket, preventing the wedge from seating fully. This leads to internal leakage and eventual seizing of the valve.

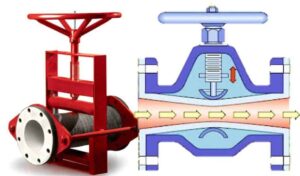

Knife Gate Valve (The Beveled Blade)

A knife gate valve is designed without a bottom pocket.

The Solution: The gate is a thin, sharpened blade (the knife) that slices through thick media. As it closes, it pushes solids out of the way or cuts through them, seating against a resilient or metal seal. Any excess material is simply flushed downstream.

2. Media Type: Clean vs. “Dirty” Service

Gate Valve: Reserved for clean fluids (water, steam, oil, gas). It provides a bubble-tight shutoff in both directions and can handle extremely high pressures (up to Class 2500).

Knife Gate Valve: Engineered for “dirty” or heavy media (slurry, pulp, wastewater, bulk powders). It excels where solids would clog a standard valve, though it is typically rated for lower pressures (Class 150).

3. Comparison Matrix: High-Performance Selection

| Feature | Standard Gate Valve | Knife Gate Valve |

| Sealing Mechanism | Wedge in a bottom pocket | Beveled blade (no pocket) |

| Clog Resistance | Low (Solids jam the pocket) | High (Self-cleaning) |

| Pressure Rating | Low to High (Up to 6000+ PSI) | Low (Typically < 300 PSI) |

| Seal Direction | Bi-directional (Standard) | Uni-directional (Standard) |

| Weight & Space | Heavy / Wide Face-to-Face | Light / Slim Wafer Design |

| Typical Media | Steam, Potable Water, Gas | Mining Tailings, Paper Pulp, Sludge |

4. Key Professional Insight: Uni-directional vs. Bi-directional

One area where buyers often get confused is the sealing direction of a knife gate valve.

Uni-directional (Standard): Most knife gate valves only seal when pressure is pushing the blade against the seat. If the pressure comes from the other side, the valve will leak.

Bi-directional: If your system has backflow or requires sealing from both sides, you must specify a Bi-directional Knife Gate Valve, which usually features reinforced rubber sleeves on both sides of the blade.

5. Maintenance and Service Life

Maintenance Advantage: Knife gate valves are significantly easier to maintain in the field. Because they are thinner (Wafer or Lug style), they take up less space in the pipeline and are easier to remove for seat replacement.

Corrosion Protection: For corrosive slurries, a stainless steel knife gate valve is often the most cost-effective solution because the body uses less material than a bulky standard gate valve.

Conclusion: Which One Do You Need?

The choice comes down to the solids content of your fluid:

Choose a Gate Valve for high-pressure, clean liquid, or steam applications where a perfect bi-directional seal is required.

Choose a Knife Gate Valve for any media containing fibers, grit, or high concentrations of solids where clogging is the primary risk.