In the high-stakes world of industrial process control—spanning petrochemicals, power generation, and chemical manufacturing—the choice between a pneumatic and an electric valve actuator is a fundamental engineering decision. While both serve to automate fluid control, their core operating principles lead to vastly different performance profiles in terms of safety, speed, and resilience.

This article dissects the fundamental debate between pneumatic actuator vs electric actuator, highlighting the five critical differences that determine which technology is the superior choice for your vital industrial valves.

Table of Contents

Toggle1. Core Difference 1: Intrinsic Safety and Explosion Risk

In environments classified as hazardous (where flammable gases or vapors are present), safety is the primary concern. The actuation principle of the pneumatic valve grants it a significant, inherent advantage.

Pneumatic Actuator Advantage: These valves operate purely on compressed air pressure, eliminating the need for electrical power at the actuator itself. This means they cannot produce electrical sparks, arc faults, or excessive heat from motor windings. They are intrinsically safe and easily meet stringent explosion-proof standards (e.g., ATEX, Ex ratings) without complex enclosures.

Electric Actuator Shortcoming: Electric actuators rely on motors and circuits. Even when housed in heavy, specialized explosion-proof (Ex d) enclosures, the potential for internal electrical fault, winding failure, or heat generation remains an intrinsic safety risk that must be managed.

2. Core Difference 2: Response Speed and Emergency Control

In emergency shut down (ESD) systems, the speed at which a valve isolates the process is paramount. Pneumatic actuators are simply faster.

Pneumatic Actuator Advantage (Speed): Compressed air is highly fluid and can fill a cylinder almost instantaneously. This allows pneumatic actuators to move a valve stem from fully open to fully closed in a fraction of a second, typically ranging from 0.5 to 1 second. This rapid response is crucial for mitigating accidents like pipeline overpressure.

Electric Actuator Shortcoming (Latency): Electric actuators rely on a motor and a gearbox/screw mechanism to convert rotational motion into linear thrust. The process of motor startup, acceleration, and mechanical translation introduces unavoidable delays. Equivalent electric valves often require 3 to 5 seconds or more to complete the same stroke.

3. Core Difference 3: Reliability and Environmental Resilience

Industrial applications often require equipment to tolerate high heat, severe cold, vibration, and moisture. Here, the simple mechanics of pneumatic systems excel.

Pneumatic Actuator Advantage (Resilience): The design, which consists of a durable piston/diaphragm and spring, has very few moving parts. It is highly resistant to heat, cold, and vibration. Pneumatic actuators can be built entirely from stainless steel, offering exceptional corrosion resistance in harsh, humid environments (like offshore platforms).

Electric Actuator Shortcoming (Vulnerability): Electronic components—such as circuit boards, encoders, and insulation—are highly sensitive to thermal cycling, high moisture levels, and strong vibration. Failure of any single electronic component can render the entire actuator useless.

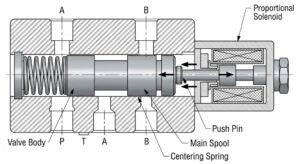

4. Core Difference 4: Precision and Modulation

When it comes to continuous throttling and subtle flow adjustment, the capabilities shift toward electric actuation.

Electric Actuator Advantage (Precision): Electric actuators, particularly those using servo or stepper motors with high-resolution encoders, provide excellent positional control. They maintain position accurately without “drifting” and are ideal for precise, continuous modulation of flow (e.g., maintaining exact temperature or level setpoints). They offer very low backlash.

Pneumatic Actuator Requirement: While capable of modulation, a pneumatic actuator requires an expensive, sophisticated smart positioner to compensate for the inherent compressibility of air and achieve the same level of fine precision that an electric actuator provides natively.

5. Core Difference 5: Total Cost of Ownership (TCO)

The financial comparison must account for initial purchase price, energy source costs, and long-term maintenance.

| Cost Factor | Pneumatic Actuator | Electric Actuator |

| Initial Purchase | Lower (Simple mechanics, no motor/electronics). | Higher (Includes motor, gearbox, control electronics). |

| Energy Source Cost | Requires a costly centralized air compressor and drying system (high upfront cost). | Relies on existing electrical supply (low infrastructure cost). |

| Maintenance & Longevity | Low maintenance frequency; long life. Easy and cheap to replace seals. | Higher maintenance frequency for electronics. Costly to replace failed motors or control boards. |

In short, pneumatic systems incur high infrastructure costs (the air system), but electric systems incur higher component replacement costs. For large fleets of valves, the lower maintenance cost and longer life of pneumatics often result in a superior TCO.

Summary: Making the Final Selection

The choice between the electric actuator vs pneumatic actuator is fundamentally a trade-off between Resilience/Speed and Precision.

| Application Scenario | Preferred Actuator | Key Reason |

| Emergency Shut Down (ESD) | Pneumatic | Sub-second response speed and intrinsic safety in hazardous zones. |

| Hazardous/Explosive Areas | Pneumatic | Eliminates ignition sources (superior safety compliance). |

| Precision Flow Control | Electric | Superior continuous, repeatable positional accuracy and high stiffness. |

| Remote/Isolated Areas | Electric | No need for centralized air lines or compressors. |

For the majority of critical industrial valves, the non-negotiable requirements of safety and speed ensure that the robust pneumatic actuator remains the dominant and preferred technology.