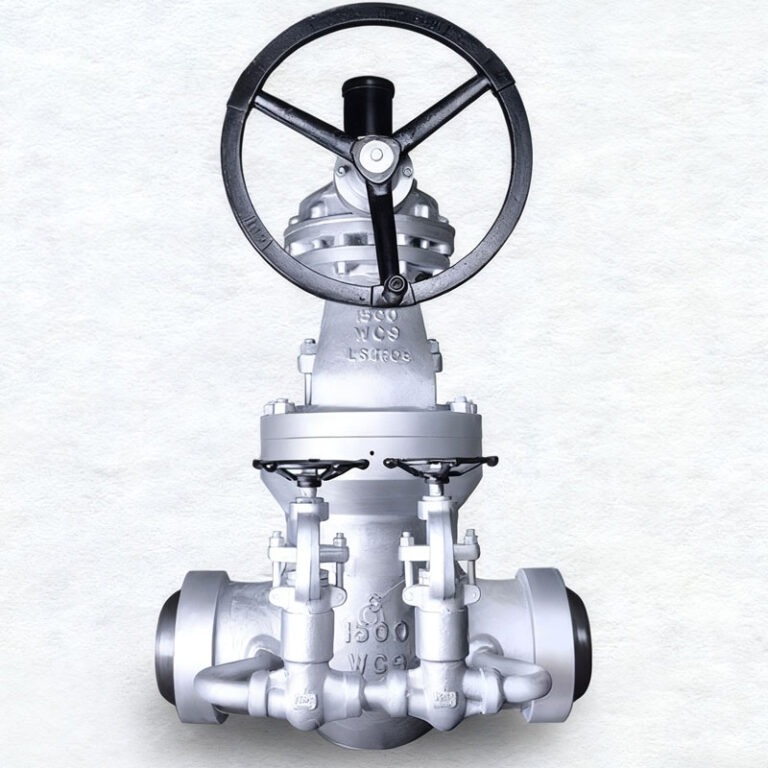

Forged Titanium Alloy Gate Valve

The Forged Titanium Alloy Gate Valve represents the pinnacle of on/off isolation technology for critical, severe service applications. It combines the metallurgical superiority of forged construction with the unparalleled corrosion resistance of Titanium alloys, ensuring maximum durability, safety, and reliability in the harshest industrial environments.

🔑 Key Characteristics & Engineering Advantages

| Feature | Detail | Impact on Performance |

| Forged Construction | The valve body and bonnet are produced from a single piece of forged Titanium alloy. | Superior Integrity: Provides enhanced grain structure, greater density, and superior ductility compared to cast bodies. This virtually eliminates porosity, yielding a high-strength, durable, and inherently leak-tight pressure boundary. |

| Titanium Alloy Material | Utilizes high-grade Titanium alloys (e.g., Gr2, Gr5, etc.) chosen for their properties. | Strength-to-Weight Ratio: Provides high mechanical strength while remaining lightweight, which is beneficial for complex installations. |

| Gate Mechanism | Operates by lifting a solid wedge (gate) entirely out of the flow path. | Full Port, Minimal Pressure Drop: Creates a complete, unobstructed flow opening when fully open, ideal for isolation where throttling is not required. |

| Exceptional Corrosion Resistance | Titanium forms a dense, stable, passive oxide layer on its surface. | Severe Service Reliability: Highly resistant to a wide range of corrosive substances, including strong acids, chlorine, and critically, saltwater and brine. |

🏭 Ideal Application Environments

This valve is specified for industries where valve failure due to material corrosion is unacceptable and poses a high risk to safety and production:

- Chemical Processing: Used in pipelines handling highly aggressive and oxidizing chemicals, ensuring long service life and process containment.

- Petrochemical Industry: Critical isolation points in specialized corrosive streams where standard alloys quickly degrade.

- Maritime and Offshore: Ideal for Seawater Service, desalination plants, and offshore platforms due to its excellent resistance to chloride-induced corrosion.

- Aerospace & High-Tech: Selected in certain applications requiring high strength, low weight, and resistance to environmental stress.

📋 Technical Summary

| Parameter | Focus |

| Function | On/Off Isolation (Non-Throttling) |

| Construction | Forged (Superior to Cast) |

| Material | Titanium Alloy (Excellent Corrosion Resistance) |

| Mechanism | Wedge Gate (Full Port) |

| End Connection | Flanged or Weld-End |

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.