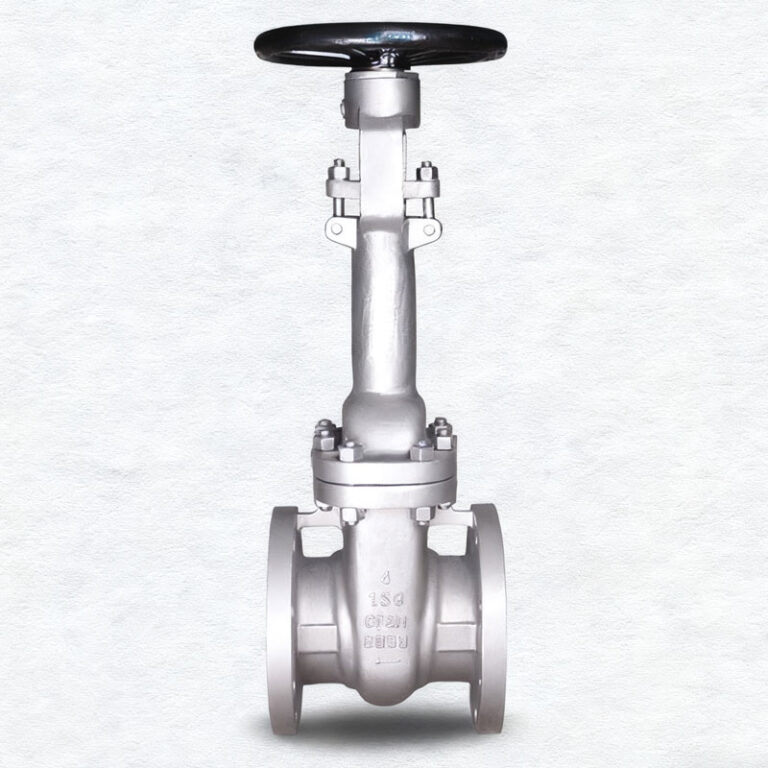

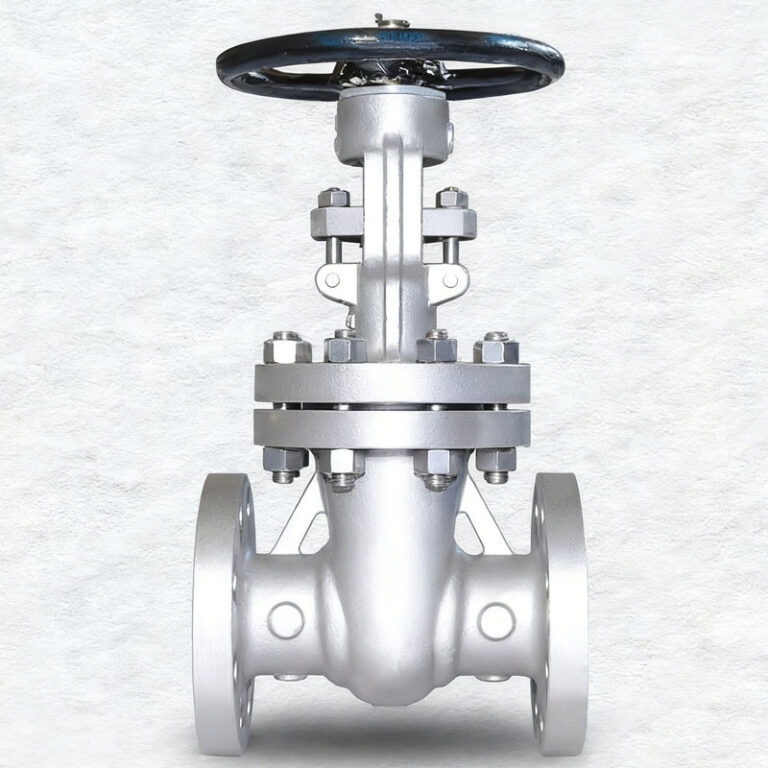

Full Port Gate Valve – 6 Inch, Class 300, 316L RTJ Flange

Engineered for critical high-flow applications, this Full Port Gate Valve offers uncompromising fluid integrity and tight shut-off capabilities. Constructed from premium 316L Stainless Steel, this valve is ideal for corrosive media and high-pressure process lines demanding zero flow restriction.

Key Product Specifications

| Specification | Detail |

| Nominal Size (DN/Inch) | DN150 / 6 Inch (Available up to 24 Inch) |

| Pressure Class | Class 300 (PN40) |

| Connection Type | Flanged, RTJ (Ring Type Joint) face standard |

| Flange Standard | ASME B16.5, JIS B2220 (Customizable) |

| Material Grade (Body/Bonnet) | ASTM A182 F316L / ASTM A351 CF3M (Low Carbon Stainless Steel) |

| Gate/Wedge Material | ASTM A182 F316, 304+Stellite (Optional Hard Facing) |

| Design Standard | API 600, API 603 |

| Applicable Medium | Water, Steam, Oil, Natural Gas, Corrosive Chemicals |

| Minimum Order Quantity (MOQ) | 1 Piece |

1. Full Bore Design: Unrestricted Flow

The core advantage of this valve is its Full Port (Full Bore) Design.

Zero Pressure Loss: When fully open, the port size is equal to the pipe’s internal diameter, providing a clear, unrestricted flow path. This is crucial for maximizing system efficiency and minimizing pumping energy costs.

Suitability for Pigging: The full bore ensures the smooth passage of PIGs (Pipeline Inspection Gauges) or cleaning tools, making it indispensable for pipelines requiring regular maintenance and inspection.

2. Premium 316L Stainless Steel Construction

The use of 316L Stainless Steel makes this valve suitable for demanding environments:

Corrosion Resistance: 316L offers superior resistance to pitting and crevice corrosion, particularly against chlorides, sulphates, and dilute acids, compared to standard 304/304L.

High Temperature/Pressure: The robust forging (ASTM A182 F316L) and casting (ASTM A351 CF3M) materials ensure stable operation up to Class 300 pressure and high-temperature service (as per ASME B16.34).

3. Structure and Operation

Structure Type

Rising Stem (OS&Y – Outside Stem and Yoke): This structure allows for external visual confirmation of the valve’s position (open/closed). The stem thread is outside the pressurized medium, protecting it from corrosion and high temperatures.

Optionally available in Non-Rising Stem (NRS) for limited space applications.

Power and Actuation

Standard Operation: Handwheel (Manual).

Automated Options: Gear Operation (for large diameters and high torque) or Electric Actuator for remote control systems.

4. High-Integrity Flange Connections

RTJ Flange: The Ring Type Joint (RTJ) flange face is specified for high-pressure and high-temperature services, offering a superior metal-to-metal seal that minimizes the risk of fugitive emissions and ensures system integrity.

Connection Options: Flanged (Standard), Threaded, and Socket Weld are also available based on customer requirements.

Why Choose Our Full Port Gate Valve?

This valve combines the robust, industry-compliant design of an API 600/603 gate valve with the superior metallurgy of 316L, delivering a reliable shut-off solution for critical applications where maximum flow and minimal maintenance are non-negotiable.

Available Sizes & Pressure Classes:

Size: DN50 (2 Inch) to DN600 (24 Inch)

Pressure: Class 150 to Class 1500

Contact us today for a quote on your specific Full Port Gate Valve requirement.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.