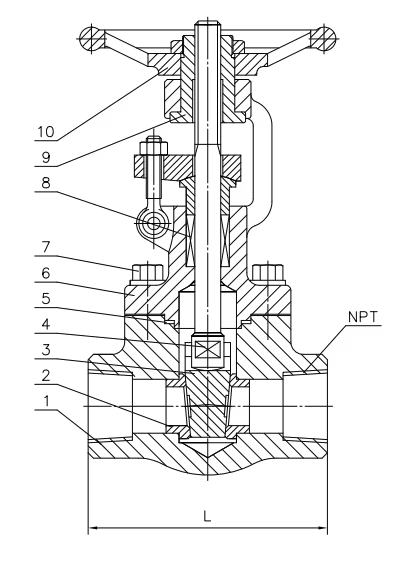

High-Pressure Integrity: Forged Steel Gate Valve Class 800 (API 602)

Engineered for severe service conditions, our Class 800 Forged Steel Gate Valve provides superior isolation for critical piping systems. Built in compliance with API 602 and tested to API 598 standards, this robust valve is the ultimate choice for high-pressure, high-temperature applications across the petrochemical, power generation, and oil & gas industries.

Key Product Specifications

| Specification | Detail |

| Design Standard | API 602 |

| Testing Standard | API 598 |

| Nominal Pressure Class | Class 800 (Available up to 2500LB) |

| Nominal Size Range | DN15 to DN50 (1/2 Inch to 2 Inch) |

| Body Construction | Forged Steel (A105) |

| Structure | Rising Stem (OS&Y), Bolted Bonnet |

| Connection Types | NPT, Socket Weld (SW), Butt Weld (BW) |

| Applicable Medium | Water, Steam, Oil, Gas, and various non-corrosive fluids |

| Temperature Rating | Up to 80°C (Standard configuration; higher temperatures available) |

1. Construction and Safety: Forged Steel Advantage

This valve utilizes forged construction, which is mandatory for Class 800 and higher small-bore valves, ensuring unmatched strength and integrity.

Forged Body Material: The body and bonnet are forged from ASTM A105 Carbon Steel (or A182 LF2/F11 for low temperature/alloy service). Forging eliminates porosity and structural defects common in castings, providing superior density and pressure containment.

Blowout-Proof Stem: The stem is designed to prevent ejection under system pressure, enhancing operational safety.

Pressure Rating: Designed specifically for Class 800 service, guaranteeing reliable performance under high static and dynamic pressures.

2. OS&Y Structure: Reliability and Maintenance

The Outside Screw and Yoke (OS&Y) rising stem design is preferred in critical isolation services.

External Threads: The stem threads are located outside the valve body (in the yoke assembly), protecting them from the line fluid and high temperatures. This minimizes corrosion and prevents thread galling.

Visual Confirmation: The rising stem provides clear, instant visual indication of the valve’s position (open or closed) from a distance.

3. Versatile Connection Options

Designed for permanent and highly secure piping connections, this valve offers multiple end types:

Socket Weld (SW): Ideal for smaller piping (DN50 / 2 Inch and below) where high pressure and thermal cycling are present, providing excellent leak resistance.

NPT Threaded: Common for utility lines and instrumentation connections, offering easy installation and maintenance.

Butt Weld (BW): Used for permanent, high-integrity connections, reducing the number of potential leak paths (available upon request).

4. Material Options and Metallurgy

We offer a range of material configurations to suit specific fluid types and temperatures:

| Component | Standard Material | High-Integrity Material Options |

| Body/Bonnet | A105 Forged Carbon Steel | LF2 (Low Temp), F11/F22 (Alloy), F316L (Stainless Steel) |

| Wedge/Disc | F6a (13% Cr) | F316L, F51 (Duplex) |

| Stem | 410 Stainless Steel | 304L, 316L |

5. Operation and Compliance

Operation: Supplied standard with a Handwheel for manual operation. Gearboxes and electric actuators are available for automated applications.

API 602 Standard: Strict adherence to this standard ensures the valve meets rigorous requirements for dimensions, material specifications, wall thickness, and testing procedures for small nominal pipe size (NPS) valves.

For unmatched pressure integrity and reliability in your high-temperature process lines, choose our API 602 Forged Steel Gate Valve.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.