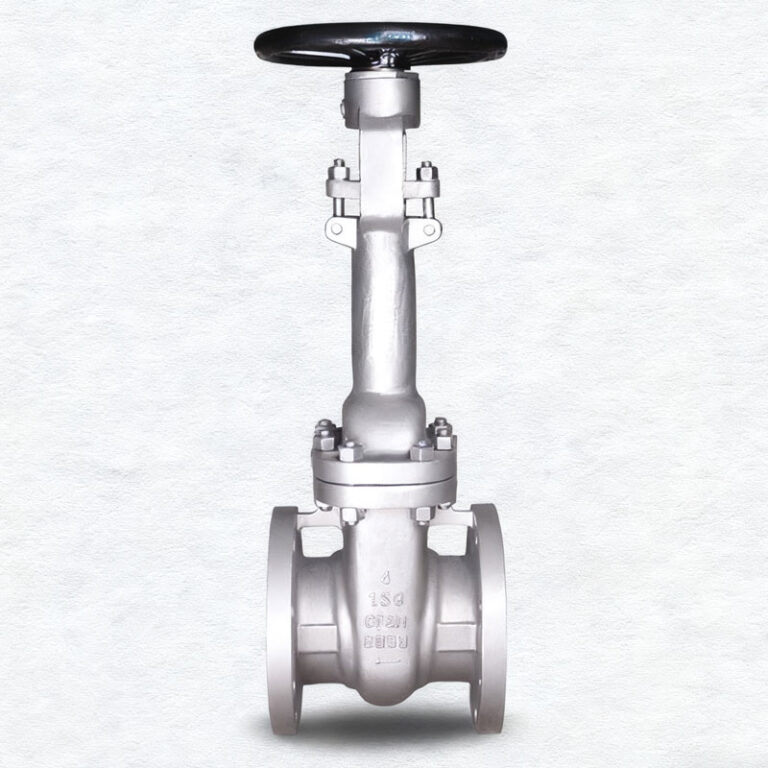

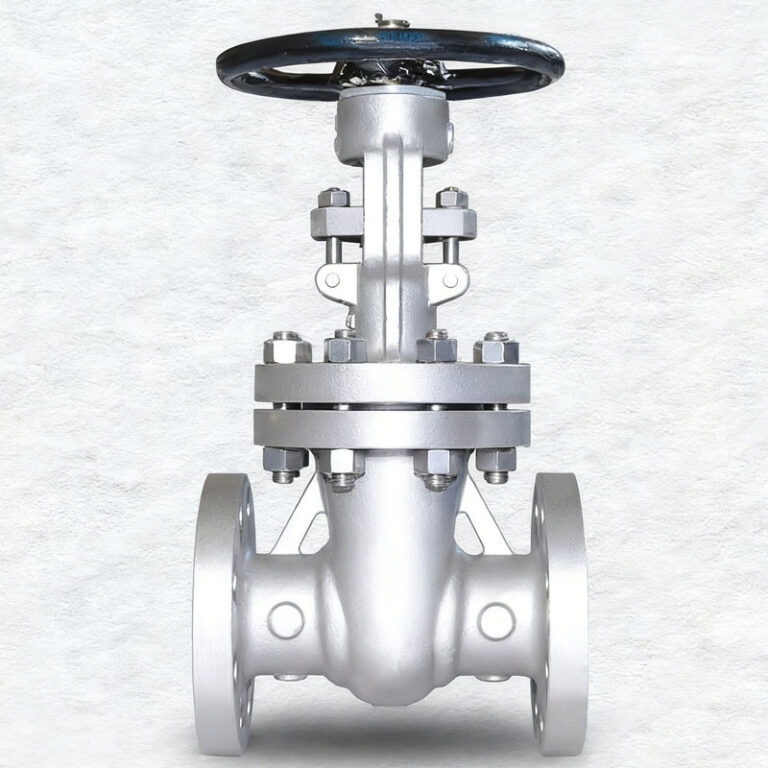

Precision Split Wedge Gate Valve: The Ultimate Solution for Seating Flexibility

Essential Specs:

Design Standard: API 600 / ASME B16.34

Pressure Class: Class 150 – 2500 (PN20 – PN420)

Wedge Type: Two-piece Independent Split Wedge

Sealing: Bi-directional, Self-aligning

Engineered for Self-Alignment and Tight Sealing

Traditional solid wedge valves require the valve body seats to be perfectly parallel to the wedge at all times. In the real world, pipe stress and thermal expansion can slightly distort valve bodies. The Split Wedge Gate Valve features a two-piece wedge connected by a universal “ball-and-socket” joint, allowing each wedge half to independently adjust to the seat angle.

Core Advantages:

Self-Aligning Seating: Each half of the wedge can tilt independently, ensuring a tight seal even if the valve body has suffered minor distortion from pipeline stress.

Reduced Operating Torque: Because the wedge doesn’t need to be “crushed” into the seat to achieve a seal, the torque required to open and close the valve is significantly lower.

Bi-directional Sealing: The design naturally handles pressure from either direction, with line pressure assisting the downstream wedge half for a tighter seal.

Key Design Features

Ball-and-Socket Joint: The two wedge halves are joined by a robust internal mechanism that allows for multi-directional movement, ensuring the wedge always finds the perfect seating position.

Non-Sticking Design: The split wedge is far less likely to become “stuck” in the closed position due to temperature changes compared to a solid wedge.

Full Stellite #6 Hardfacing: To prevent erosion and wear in high-frequency service, both the wedge halves and the body seats are typically hard-faced with Stellite.

Guided Travel: Integrated body guides ensure the split wedge remains perfectly centered during its entire stroke, preventing seat rubbing and vibration.

Technical Specifications

| Feature | Standard Configuration | Optional Upgrades |

| Size Range | 2″ – 48″ (DN50 – DN1200) | Custom Large Bore available |

| Body Materials | WCB, LCB, WC6, CF8M | Duplex, Monel, Hastelloy |

| Wedge Material | Matches Body (Stellite Faced) | Full Stainless Steel |

| Stem Design | OS&Y / Rising Stem | Live-loaded packing for emissions |

| Bonnet Type | Bolted Bonnet | Pressure Seal (for Class 900+) |

Critical Service Applications

Refining & Petrochemicals: Ideal for light hydrocarbons where bubble-tight shutoff is mandatory.

Water & Waste Treatment: Used in large-diameter pipelines where body distortion from ground movement is a risk.

High-Temperature Gases: The split design accommodates the thermal expansion of gas processing lines better than solid wedges.

Corrosive Media: Often specified in Stainless Steel or Duplex for chemical plants where seat integrity is paramount.

Compliant with: API 600, API 598 (Testing), ASME B16.10, and ISO 15848.

Split Wedge Gate Valve: Frequently Asked Questions

Q: What is the main difference between a Split Wedge and a Flexible Wedge?

A: A flexible wedge is one piece with a groove cut into it; it has limited flexibility. A Split Wedge is two entirely separate pieces, offering much higher flexibility and better performance in distorted pipelines.

Q: Can this valve handle slurries?

A: While better than a solid wedge, split wedges can sometimes trap particles between the two halves. For heavy slurries, we recommend our Knife Gate or Parallel Slide options.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.