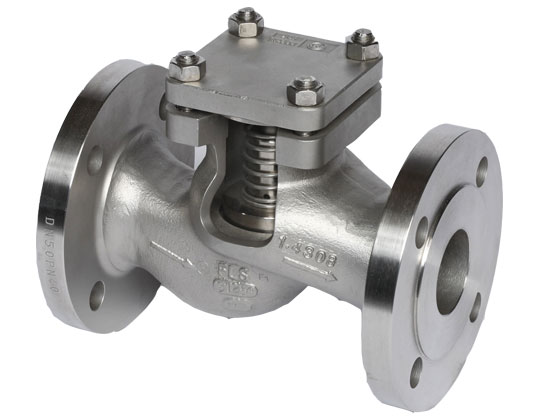

Stainless Steel Piston Type Check Valve

The Stainless Steel Piston Type Check Valve (sometimes referred to as a lift check valve) is an automatic valve designed to permit flow in one direction and prevent backflow. It uses a piston or disc guided within the body to move away from the seat when pressure is applied and return to the seat when flow ceases or reverses. This design is highly favored in high-pressure and high-temperature systems where minimal leakage is critical.

⚙️ Technical Specifications

| Parameter | Specification | Detail |

| Nominal Size (DN) | DN15 – DN400 | Wide range from ≈ 1/2” up to 16”. |

| Material | SS201, SS304, SS316L, etc. | Stainless Steel construction for corrosion resistance. |

| Connection Type | Flanged | Robust, bolted connection for pipeline security. |

| Working Pressure | 1.6MPa(≈ PN16/Class150) | Suitable for medium-pressure applications. |

| Working Temperature | < 200°C | Suitable for a wide range of fluid temperatures. |

| Applicable Media | Water, Oil, Gas, Steam, etc. | Versatile application across different fluid types. |

| Power | Automatic | No external power source required; operated by flow pressure. |

| Support | OEM, ODM, Sample | Customization and sample orders accepted. |

⭐ Key Design and Operational Features

- Piston/Disc Mechanism: The core of the valve is a guided piston or disc that moves perpendicularly to the flow direction. This design allows for precise seating and tight shut-off.

- Seating: The piston’s guided motion ensures that the seating surface aligns perfectly with the seat ring, leading to excellent sealing performance and suitability for high-pressure/high-temperature steam, gas, or liquid services.

- Corrosion Resistance: The use of materials like Stainless Steel 304 and 316L ensures superior resistance to corrosion and scaling, making the valve durable and reliable even with aggressive media.

- Installation: Piston check valves are commonly designed for horizontal installation but can also be used in vertical lines with flow directed upwards.

🏭 Application

The Piston Type Check Valve is ideal for service lines requiring tight, reliable non-return functionality under challenging conditions:

- Process Lines: Used extensively in the Chemical, Oil, and Gas industries.

- Utility Lines: Effective for Steam, High-Temperature Water, and Compressed Air.

- High-Temperature/Pressure Services: Well-suited for applications beyond the temperature limits of many resilient-seated valves.

Fast Response & Competitive Pricing Start Here

* We are not just providing simple quotes but experts in selection, calculation, and drawing.