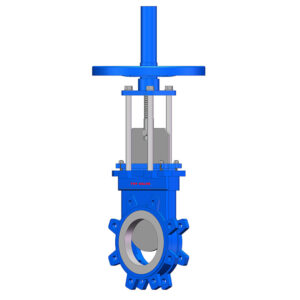

In industrial, water supply, and fire protection systems, the gate valve is the ultimate isolation tool. However, a common mistake during the design phase is overlooking the stem mechanism.

Choosing between a Rising Stem (OS&Y) and a Non-Rising Stem (NRS) isn’t just a matter of preference—it’s about balancing operational safety against spatial constraints. This guide breaks down the “why” and “when” behind each design to help you avoid costly installation errors.

Table of Contents

Toggle1. What Is a Rising Stem (OS&Y) Valve?

The OS&Y valve (Outside Screw and Yoke) is the “communicator” of the valve world. As the handwheel turns, the stem rises vertically, protruding above the handle.

The “Field Expert” Insight: Why OS&Y Saves Lives

In emergency fire protection (NFPA 13/24 standards), visibility is everything. A fire chief needs to look at a rising stem gate valve from 20 feet away and know instantly if the water supply is open. If the stem is up, the system is live.

Key Features:

Visible Status: The stem acts as a mechanical “status bar.”

Thread Protection: Since threads are outside the valve body, they aren’t corroded by the fluid.

Easy Maintenance: You can lubricate the threads without shutting down the system.

The “Catch”: You must account for vertical clearance. If you install an OS&Y valve in a low-ceiling basement, the stem might hit a cable tray or pipe before the valve is fully open.

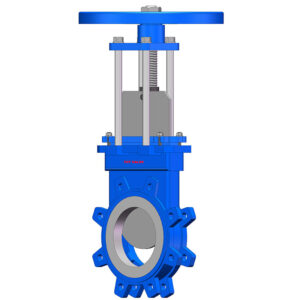

2.What Is a Non-Rising Stem (NRS) Valve?

An NRS gate valve is the “silent worker.” The stem rotates but stays fixed vertically. The gate travels up and down on internal threads within the valve body.

The Spatial Solution: Buried and Confined Service

Because the external height never changes, the non-rising stem gate valve is the king of underground water mains and cramped mechanical vaults.

Key Features:

Compact Footprint: Ideal for locations where “headroom” is non-existent.

Buried Service Ready: Designed to be operated from the surface via a “T-wrench” or paired with a Post Indicator Valve (PIV).

The “Risk”: Because the stem threads are constantly submerged in the media, they are vulnerable to Thread Galling (seizing) if the fluid is corrosive or contains sand/debris.

Because the stem remains in place, the valve’s external height stays constant — making it ideal for underground or confined installations.

3. Comparison Matrix: At-A-Glance Decision

| Feature | Rising Stem (OS&Y) | Non-Rising Stem (NRS) |

| Position Indication | Instant Visual Confirmation | None (Requires external indicator) |

| Stem Durability | High (Protected from media) | Lower (Threads are submerged) |

| Space Required | High Vertical Clearance | Minimal / Space-Saving |

| Maintenance | Easy to inspect & lubricate | Harder (Requires disassembly) |

| Critical Failure Risk | Stem hitting overhead obstacles | Threads seizing due to debris/corrosion |

| Primary Industry | Fire Protection, Chemical, Oil & Gas | Municipal Water, Marine, Buried Lines |

4. Engineering Checklist: Which Type Do You Need?

Choose a Rising Stem Valve (OS&Y) if:

Safety is Priority One: You need to know the valve status at a glance (e.g., Fire Sprinkler Risers).

Corrosive Media: Your fluid would damage internal stem threads over time.

Above-Ground Service: You have plenty of vertical room for the stem to extend.

Choose a Non-Rising Stem Valve (NRS) if:

Buried Service: You are installing the valve underground and using a valve box or indicator post.

Tight Spaces: You are working in a marine engine room or a low-clearance vault.

Cost Sensitivity: NRS valves are generally more economical for large-scale municipal water projects.

5. Maintenance Pro-Tips: Avoiding the “Stuck Valve”

For OS&Y: Don’t let the exposed threads dry out. A biannual application of high-quality grease prevents “thread binding” caused by dust and humidity.

For NRS: In water systems, cycle the valve fully at least twice a year. This “exercises” the internal threads and flushes out sediment that could cause the gate to seize.

Packing Leaks: Both types require periodic packing nut adjustments. If you see fluid weeping from the stem, tighten the packing slightly—over-tightening will make the valve nearly impossible to turn manually.

Conclusion: Visibility vs. Compactness

The choice between Rising Stem and Non-Rising Stem valves comes down to a simple trade-off: Do you need to see it, or do you need to hide it? The OS&Y valve offers visibility and accessibility at the cost of space, while the NRS valve offers a compact, rugged solution for underground and space-limited environments.