In industrial fluid handling, valves play a critical role in regulating and isolating flow. Two commonly compared options are the slide gate valve and the knife gate valve. At first glance, they may look similar since both use a sliding mechanism to block or allow flow. However, their design, applications, and performance characteristics differ significantly.

This guide explains the differences between slide gate valves and knife gate valves, helping you choose the right one for your system.

Table of Contents

Toggle⚙️ What Is a Slide Gate Valve?

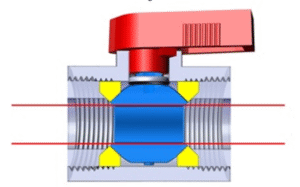

A slide gate valve (also known as a sliding gate valve) is a valve that uses a flat gate or plate to slide across the flow path, allowing or blocking material movement.

Primary Use: Designed mainly for dry bulk materials such as powders, pellets, and grains.

Industries: Agriculture, cement, food processing, and bulk solids handling.

Design Features:

Flat sliding plate (no sharp cutting edge).

Operates well in gravity-fed or low-pressure applications.

Provides isolation rather than precise flow control.

🔧 What Is a Knife Gate Valve?

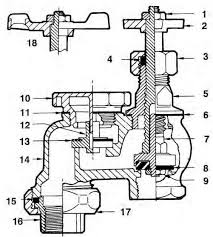

A knife gate valve is an industrial valve featuring a sharp-edged blade designed to cut through thick, slurry-type media.

Primary Use: Designed for liquids containing solids, such as slurry, wastewater, or pulp.

Industries: Mining, wastewater treatment, pulp and paper, chemical processing.

Design Features:

Knife-like blade cuts through fibrous or abrasive materials.

Excellent for on/off control in slurry pipelines.

Available in both resilient-seated and metal-seated designs.

🔍 Slide Gate Valve vs. Knife Gate Valve: Comparison Table

| Feature | Slide Gate Valve | Knife Gate Valve |

|---|---|---|

| Medium | Dry bulk materials (powders, grains, pellets) | Liquids with solids (slurry, pulp, wastewater) |

| Design | Flat sliding plate | Sharp-edged blade |

| Operation | Gravity-fed, low pressure | Low to medium pressure, abrasive/corrosive media |

| Sealing | Less sealing capability | Provides better sealing against fluids |

| Applications | Silos, hoppers, conveyors | Pipelines carrying slurry, sludge, pulp |

| Cost | Generally lower | Slightly higher (depending on size/material) |

| Throttling | Limited control | Primarily on/off, not for precise throttling |

✅ Key Takeaways

Slide Gate Valves are ideal for bulk solid handling where free-flowing powders or granules need to be controlled.

Knife Gate Valves are best for slurry and liquid applications with suspended solids where a cutting action is needed.

Choosing between them depends on the type of media, pressure conditions, and whether the system handles solids or liquids.

📩 Conclusion

While slide gate valves and knife gate valves share a similar sliding mechanism, their intended uses are very different. Slide gate valves excel in dry bulk material handling, whereas knife gate valves dominate in slurry and fluid systems.

When selecting the right valve, always consider:

The type of media (dry vs. wet, solid vs. slurry)

The operating pressure

The need for sealing and durability

Making the right choice ensures longer service life, reduced maintenance, and better system efficiency.