Table of Contents

ToggleIntroduction: The Evolution of Pipeline Connections

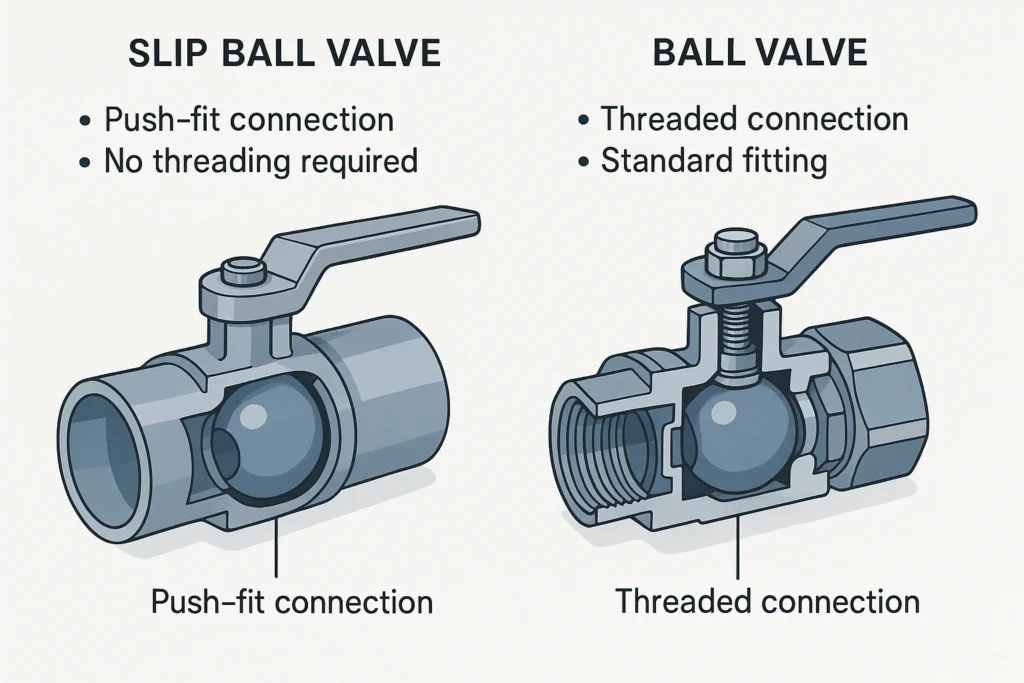

In plumbing and water systems, Ball Valves are essential for reliable ON/OFF isolation. Traditionally, these valves required soldering, solvent welding, or threading onto a pipe—methods that demand time, tools, and specific expertise.

The emergence of the Slip Ball Valve (or Push Connect Ball Valve) has fundamentally changed this, offering a revolutionary approach to quick, tool-free installation. This guide explores the core differences between the standard valve and the slip valve to help you select the most efficient connection type for your project.

I. Defining the Slip Ball Valve: The Push-to-Connect Revolution

What is a Slip Ball Valve?

A Slip Ball Valve is a type of ball valve designed with a unique end connection that allows the valve to be quickly slipped or pushed directly onto the pipe end without the use of solder, glue, or specialized threading tools. They are often broadly referred to as a slip valve due to this push-in feature.

Mechanism: The valve incorporates an internal gripping ring (collet) and an O-ring seal. When the pipe is pushed into the fitting, the gripping ring locks the pipe in place, and the O-ring creates a watertight seal.

Key Advantage: This push connect ball valve technology drastically reduces installation time and minimizes the risk of fire hazards associated with soldering.

II. Slip Ball Valve vs Standard Ball Valve: The Core Differences

The comparison between a slip ball valve vs ball valve (standard connection) centers on installation method, flexibility, and pressure integrity.

| Characteristic | Slip Ball Valve (Push Connect) | Standard Ball Valve (Threaded/Soldered) |

| Installation Method | Tool-Free Push-to-Connect | Requires soldering torch, pipe threading, or solvent cement. |

| Speed & Effort | Extremely fast and easy; minimal labor required. | Time-consuming; requires cooling time or curing time. |

| Repair & Adjustments | Highly versatile; can often be removed and reinstalled easily. | Permanent; replacement requires cutting the pipe or rethreading. |

| Media Compatibility | Primarily used for Water and non-critical applications. | Used for all media: Gas, Steam, Chemicals, and Water. |

| Pressure Rating | Typically rated for standard residential/commercial pressures. | Available in ratings up to ANSI Class 2500 (High Pressure). |

III. Application & Value: When to Choose a Slip Valve

Choosing a slip ball valve is primarily a decision about labor efficiency and project scope.

A. Slip Valves for Residential and Light Commercial Plumbing

Slip ball valves are the optimal choice for domestic water supply lines and light commercial repairs.

Fast Repair: They are essential for emergency plumbing fixes where water needs to be shut off and a new valve installed in minutes, not hours.

Material Flexibility: They work seamlessly with common residential pipe materials, including copper, PEX, and CPVC.

Convenience: For DIYers or contractors looking to maximize labor efficiency, the push connect feature offers unparalleled convenience.

B. Standard Valves for Industrial and Critical Service

Traditional ball valves (welded, flanged, or high-pressure threaded) remain indispensable for industrial processes.

High Pressure/Temperature: Their rigid connection methods are necessary to withstand extreme pressure and temperature cycles that O-ring seals cannot handle.

Zero Leakage Requirement: In hydrocarbon or chemical processing, the permanence and sealing integrity of a welded or flanged joint cannot be replaced by a slip fitting.

Conclusion: Balancing Speed and Integrity

The slip ball valve or push connect ball valve offers a superior solution for rapid, cost-effective isolation in non-critical water and plumbing systems. They save significant time and money on installation costs.

However, the traditional ball valve remains the standard for all industrial, high-pressure, and critical service applications where the integrity of a permanent connection outweighs the need for installation speed.