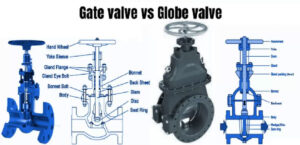

In the world of piping engineering, tradition can be expensive. For decades, the Gate Valve has been the default choice for isolation. However, as material and labor costs skyrocket, savvy project managers are realizing that for large-diameter pipelines (10 inches and above), the gate valve is often an “over-engineered” and over-priced solution.

If your project is still using massive, heavy gate valves for general isolation, you aren’t just buying a valve—you are paying for excess metal, specialized installation crews, and heavy-duty pipe supports. Here is why switching to High-Performance Butterfly Valves is the smartest cost-saving move for your next project.

Table of Contents

Toggle1. The Weight-to-Cost Battle: 300kg vs. 50kg

The most immediate saving is in the metal itself. A butterfly valve is a “wafer” or “lug” design, meaning it only takes up a fraction of the space and material of a gate valve.

The Reality Check: A standard 12-inch (DN300) Gate Valve can weigh approximately 300kg. In contrast, a 12-inch High-Performance Butterfly Valve weighs only about 50kg.

The Ripple Effect: * Shipping: You can ship six butterfly valves for the cost of one gate valve.

Infrastructure: Because butterfly valves are 80% lighter, you don’t need heavy-duty, reinforced pipe hangers and supports, which significantly reduces the total project bill of materials (BOM).

2. Installation Efficiency: Minutes vs. Hours

Time is money, especially in offshore, refinery, or large-scale HVAC construction.

Gate Valve Installation: Requires a crane or heavy-duty rigging equipment, a team of at least 4 workers, and several hours to align, bolt, and secure.

Butterfly Valve Installation: Because it is lightweight and slim, 2 workers can typically install it in 20 minutes using basic tools. No cranes, no heavy rigging, and significantly lower labor risks.

3. Performance & Sealing: When is the Butterfly Better?

We must be honest: a Gate Valve has a “full-bore” design, meaning when it is open, there is zero flow resistance. However, in 80% of industrial applications, this tiny pressure drop advantage is irrelevant compared to the sealing benefits of a butterfly valve.

Better Sealing: Standard gate valves are metal-seated and prone to “passing” (leaking) if any debris gets stuck in the bottom groove. High-Performance Butterfly Valves (Double Offset) utilize advanced soft or laminated seats that provide a Class VI “Bubble-Tight” shutoff every time.

Price Advantage: For large sizes (10″+), a High-Performance Butterfly Valve is typically 30% to 50% cheaper than a gate valve of the same rating.

4. Comparison Data: 12″ (DN300) Valve Face-Off

| Feature | 12″ Cast Steel Gate Valve | 12″ HP Butterfly Valve | The Winner |

| Weight | ~300 kg | ~50 kg | Butterfly |

| Face-to-Face | 350 mm | 80 mm | Butterfly |

| Install Time | 3 – 4 Hours | 30 Minutes | Butterfly |

| Equipment | Crane / Rigging required | Hand-carried | Butterfly |

| Unit Cost | High ($$$$) | Low ($$) | Butterfly |

5. When Should You STILL Use a Gate Valve?

As a manufacturer, we want you to have the right valve, not just the cheaper one. You should stick with a Gate Valve only if:

You need to run a “PIG” through the line to clean it (Butterfly discs block the center of the pipe).

Your system requires absolutely zero pressure drop.

You are dealing with highly abrasive media that would constantly strike a butterfly disc.

Conclusion: It’s Time to Modernize Your Spec Sheet

For isolation in water, chemicals, and steam systems, the High-Performance Butterfly Valve is the modern alternative that offers better sealing at a fraction of the weight and cost. By making the switch, you aren’t just choosing a different valve; you are optimizing your entire pipeline’s economic efficiency.

💡 Cost-Saving Consultation

Are you planning a new project or looking to upgrade an existing line? Don’t let old designs drain your budget.