It is a common nightmare: you need to shut off the water for a repair or an emergency, but the gate valve is stuck. Whether it is seized due to mineral buildup, corrosion, or long periods of inactivity, forcing a stuck valve can lead to a broken stem or a catastrophic leak.

If your gate valve turns but won’t open, or if the water shut-off valve is stuck solid, follow this professional guide to safely restore operation without damaging your plumbing.

Table of Contents

Toggle1. Initial Diagnosis: Is it Seized or Broken?

Before applying force, determine the nature of the problem:

The Seized Valve: The handle will not move at all. This is usually caused by “internal scaling” or corrosion between the gate and the seat.

The Broken Stem: The gate valve just keeps turning or the handle spins without any resistance. This usually means the internal stem has snapped or the threads have stripped. In this case, the valve must be replaced.

2. Step-by-Step: How to Loosen a Stuck Water Valve

If the valve is simply seized, follow these steps in order of increasing intensity:

Step 1: The Lubrication Soak

Don’t use brute force immediately. Apply a high-quality penetrating oil (like WD-40 Specialist or PB Blaster) to the point where the stem enters the valve body.

Pro Tip: Let it sit for at least 20–30 minutes. The oil needs time to travel down the threads to the packing nut.

Step 2: The “Hammer Tap” Method

Using a small hammer or the handle of a wrench, gently tap the valve body and the top of the stem. These micro-vibrations help break the bond of mineral deposits and rust inside the valve.

Step 3: The Wrench and Lever (Use Caution)

If the valve is still a stuck water valve, use a pipe wrench for better leverage.

The “Rocking” Technique: Instead of just pulling hard in one direction (Close), try to “rock” the valve. Turn it slightly toward “Open,” then back to “Closed.” This back-and-forth movement helps grind away the internal scale.

Warning: If you feel the metal “give” but the water flow doesn’t change, the stem may have snapped. Stop immediately.

Step 4: Gentle Heat

For extreme cases, use a hair dryer or a heat gun on the valve body (not the stem). The heat causes the valve body to expand slightly faster than the gate, which may break the seized seal.

Do not use a torch near flammable walls or if the valve has plastic components.

3. Why Do Gate Valves Keep Spinning or Sticking?

Most standard brass or iron gate valves fail because of their design:

Mineral Buildup: In hard water areas, calcium and lime accumulate in the “pocket” at the bottom of the valve, preventing the gate from seating.

Corrosion: Over years of inactivity, the metal stem and gate bond together.

Low-Quality Materials: Inexpensive valves often have thin stems that shear off when you try to fix a stuck water shut-off valve.

4. The Permanent Solution: Upgrade to Anti-Seize Technology

If you are tired of dealing with a stuck water shut-off valve, it may be time to move away from traditional metal-to-metal gate valves.

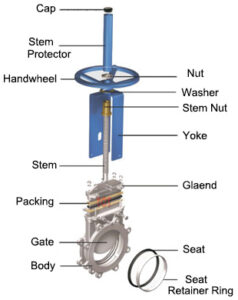

Our Ceramic Knife Gate Valves are engineered specifically to solve the “stuck valve” problem:

Structural Ceramic Seats: Unlike metal, ceramics do not rust or bond with minerals.

Scraping Action: The sharp gate edge physically scrapes away scale and debris every time it moves.

NRS (Non-Rising Stem) Options: Ideal for tight spaces, ensuring the threads remain protected from the environment.

Conclusion

A stuck gate valve can be a major headache, but with patience and the right technique, most can be loosened. However, if your valve is old and prone to seizing, a gate valve rebuild or replacement is the only way to ensure your facility remains safe.