A swing check valve is one of the most widely used automatic valves in piping systems. Its primary function is to prevent backflow of the medium and ensure unidirectional flow. With its simple structure, automatic operation, and low flow resistance, the swing check valve plays a crucial role in water supply, petrochemical, energy, and HVAC systems.

Table of Contents

Toggle1. Structure of a Swing Check Valve

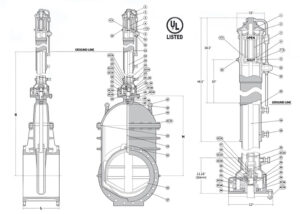

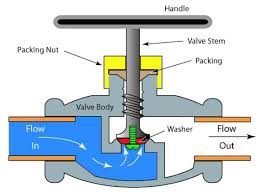

The swing check valve is designed for efficiency and reliability, typically composed of the following main components:

Valve Body:

Provides the passage for the medium. Common materials include cast iron, stainless steel, carbon steel, and bronze, selected according to pressure and medium characteristics.Valve Cover:

Mounted on top of the valve body for sealing and easy maintenance of internal parts.Disc (or Flap):

The core moving part that swings open or closed around a hinge or pin. The disc is usually round or semi-round.Hinge or Pin Shaft:

Connects the valve disc to the body, allowing it to swing freely under fluid pressure.Seat:

The sealing surface where the disc rests when closed to prevent reverse flow.Sealing Ring:

Optional soft or metal seals (EPDM, PTFE, or stainless steel) to enhance sealing performance.

The swing-type structure allows the valve to open automatically when the medium flows forward and close by gravity when the flow stops or reverses—no external power required.

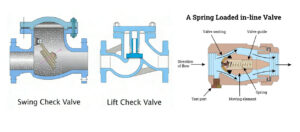

2. Working Principle of a Swing Check Valve

The operating principle relies on fluid dynamics and gravity to achieve automatic control of flow direction.

(1) Opening Process

When the medium flows in the correct direction (inlet → outlet), the fluid pressure acts on the disc, pushing it open around the hinge axis.

Once the force exceeds the weight and hinge resistance of the disc, the valve opens, allowing fluid to pass through smoothly with minimal pressure loss.

Key factors influencing valve opening:

Flow velocity: Higher velocity increases disc opening angle.

Pressure differential: Drives the opening movement.

Disc weight and hinge friction: Affect the response sensitivity.

(2) Closing Process

When the medium flow stops or reverses, the pressure on the outlet side increases, causing the disc to swing back by gravity and seat tightly on the valve seat.

This seals the passage and prevents backflow.

Key closing factors:

Back pressure: Helps accelerate disc closure.

Gravity or spring force: Ensures tight and quick sealing.

Seal integrity: Determines backflow prevention effectiveness.

(3) Dynamic Balance

Under variable flow conditions, the disc continuously adjusts its angle to balance between flow pressure and gravity.

(4) Water Hammer Consideration

If the valve closes too quickly, water hammer (a pressure surge due to sudden flow stoppage) may occur.

To minimize this, some swing check valves are equipped with dampers or slow-closing mechanisms to achieve smoother closure.

3. Advantages of Swing Check Valves

Swing check valves are widely preferred due to their simple yet robust design:

Simple and Reliable: Automatic operation without external power.

Low Flow Resistance: Full-open design allows near-straight fluid passage.

Versatile Application: Suitable for water, oil, gas, steam, and chemical media.

Durable: Resistant to corrosion and mechanical wear.

Flexible Installation: Can be installed horizontally or vertically (with hinge axis horizontal).

4. Limitations of Swing Check Valves

Despite their benefits, swing check valves also have certain limitations:

Slower Closing Speed: Relies on gravity rather than spring force.

Potential Water Hammer: Especially in high-velocity pipelines.

Directional Installation: The hinge axis must remain horizontal.

Not Ideal for Pulsating Flow: Frequent opening/closing may cause vibration or wear.

5. Common Applications

Swing check valves are reliable and cost-effective, making them ideal for many fluid systems:

Water Supply and Drainage: Prevent backflow in water pumps, municipal pipelines, and fire systems.

Oil & Gas: Maintain one-way flow in crude oil, natural gas, and refined product pipelines.

Chemical Processing: Protect reactors and process lines from corrosive backflow.

HVAC Systems: Control chilled or hot water flow direction, avoiding circulation disruption.

Power & Energy Plants: Used in boiler feedwater and cooling systems to protect pumps and turbines.

6. Selection and Installation Guide

(1) Selection Considerations

Medium Type: Choose materials resistant to corrosion and chemical attack.

Pressure & Temperature: Match the valve’s rating (PN/ANSI) to system conditions.

Pipe Size: Match nominal diameter to avoid excessive flow resistance.

Operating Environment: Consider temperature, humidity, and potential vibrations.

Water Hammer Protection: For large-diameter or high-pressure systems, select a valve with a damping or slow-closing mechanism.

(2) Installation Tips

Ensure arrow direction on valve matches medium flow direction.

Keep the hinge axis horizontal.

Clean the pipeline before installation to avoid debris damage.

Provide enough clearance for maintenance.

Secure the valve to prevent vibration during operation.

7. Maintenance and Service

Proper maintenance ensures long-term performance and safety:

Routine Inspection: Every 6–12 months, check disc, seat, and seals.

Cleaning: Remove deposits or scaling inside the valve.

Leak Test: Verify tight sealing during system shutdown.

Lubrication: Grease hinge pins periodically.

Maintenance Records: Log inspection data for performance tracking.

8. Conclusion

The swing check valve stands as the guardian of one-way flow, ensuring reliability, safety, and efficiency in countless industrial and municipal applications.

With advancements in materials and flow control technology, modern swing check valves are becoming more durable, precise, and water hammer-resistant, providing a dependable solution for today’s complex piping systems.