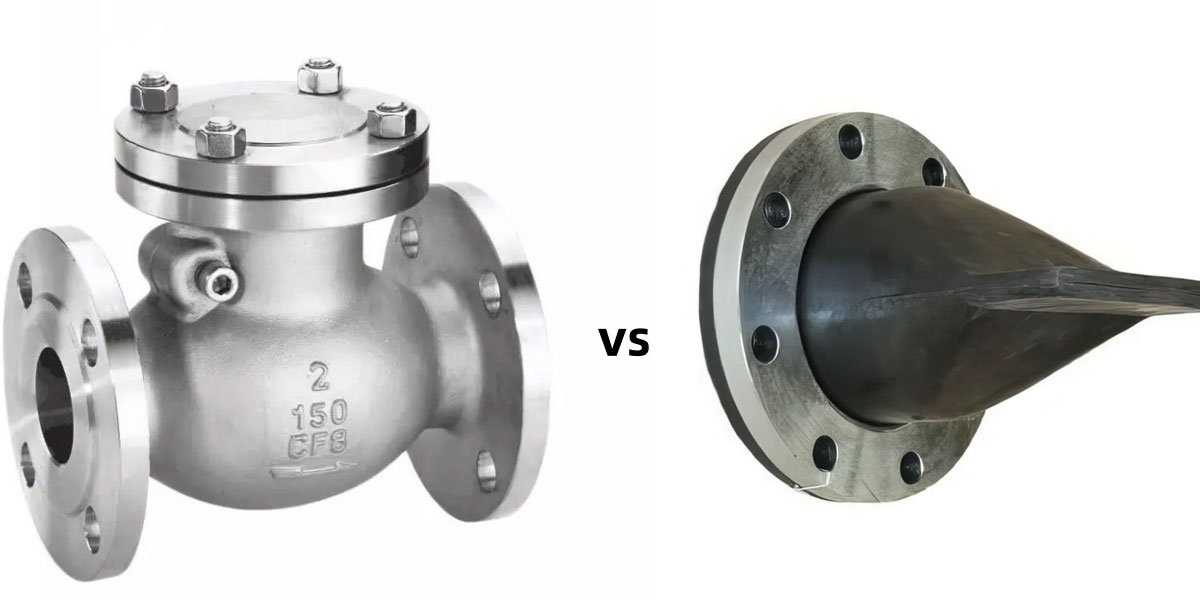

In industrial fluid systems, the check valve—or non-return valve—is the critical line of defense against backflow and pump damage. However, when dealing with wastewater containing debris or highly corrosive chemicals, traditional mechanical valves often fail.

The Swing Check Valve has long been the industry standard, but the Duckbill Check Valve is emerging as the preferred “maintenance-free” alternative for challenging environments. This guide compares these two distinct linear and rotary motion solutions to help you make the best engineering choice for your facility.

Table of Contents

Toggle1. The Swing Check Valve: The Mechanical Classic

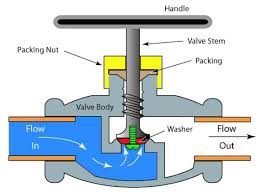

A Swing Check Valve operates using a disc that swings on a hinge or shaft.

Working Principle: When the upstream pressure exceeds the opening pressure, the disc swings away from the seat to allow flow. When the flow stops or reverses, gravity and backpressure pull the disc back to the closed position.

Best Features: These valves offer high flow capacity, low pressure drop, and excellent metal-to-metal sealing in high-pressure environments.

Limitations: They are highly susceptible to “Water Hammer” during sudden closures. Furthermore, in systems handling solids or slurries, debris can easily jam the hinge or the disc, leading to seat failure and costly downtime.

2. The Duckbill Check Valve: The Flexible, Maintenance-Free Solution

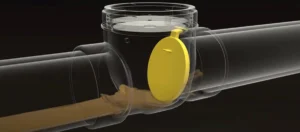

A Duckbill Check Valve is a sleeve-type valve manufactured from high-strength industrial elastomers (such as EPDM, Nitrate, or Silicone) that resembles the beak of a duck.

Working Principle: The valve relies entirely on the internal elasticity of the rubber. Forward pressure opens the “beak” to allow discharge, while backpressure squeezes the lips together to create an absolute seal.

Best Features: * Anti-Clogging: There are no mechanical parts—no hinges, shafts, or springs. Solids and debris pass through without snagging.

Corrosion Resistance: The all-rubber construction (Silicone Duckbill Valve or EPDM) makes it impervious to many harsh chemicals that would corrode metal valves.

Water Hammer Mitigation: The flexible rubber absorbs pressure surges, providing silent operation and protecting the piping.

Limitations: They have a slightly higher cracking pressure than swing checks and are generally not suited for extreme high-pressure oil and gas lines.

3. Technical Comparison Matrix

| Feature | Swing Check Valve | Duckbill Check Valve |

| Main Materials | Cast Steel, Stainless Steel, Bronze | Industrial Elastomers (EPDM / Silicone) |

| Sealing Method | Mechanical Disc on Seat | Self-Sealing (Elastic Deformation) |

| Debris Tolerance | Low (Susceptible to jamming) | Extreme (Ideal for sewage/slurries) |

| Maintenance | Periodic bearing/seal inspection | Virtually Maintenance-Free |

| Installation | Flanged, Threaded | Flanged, Slip-on (Sleeve) |

4. Typical Industrial Applications

Case A: Municipal Wastewater & Outfall Systems

For pump stations or tidal outfall lines, the Rubber Duckbill Valve is the superior choice. It prevents backflow even when sand, silt, and debris are present, outperforming swing checks which would require frequent manual cleaning in these conditions.

Case B: Clean Fluid & High-Pressure Systems

In clean water, steam, or high-pressure lubrication lines, the Swing Check Valve remains the gold standard. Its rigid metal structure can withstand higher operating temperatures and pressures than rubber components.

Case C: Chemical Processing

If you are managing aggressive acids or bases, a Diaphragm Valve or a specialized rubber duckbill is often required to ensure that the process media is completely isolated from the valve’s structural components.

5. Engineering Note: Industrial vs. Consumer Grades

When sourcing a duckbill valve, it is vital to distinguish between industrial non-return valves and small-scale consumer components. Industrial-grade valves are defined by their Back-Pressure Ratings, Durometer (Rubber Hardness), and compliance with ANSI or DIN Flange Standards.

Our Industrial Duckbill Check Valves are engineered for heavy-duty municipal and chemical service and are not compatible with small-scale medical or household appliances.