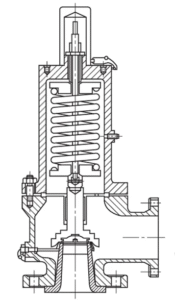

An anti-siphon valve plays a crucial role in preventing unwanted reverse flow—whether it’s fuel in an engine system or water in an irrigation setup. When this valve fails, it can lead to performance issues, safety concerns, and system malfunctions.

This guide covers the most common symptoms of a bad anti-siphon valve, how to diagnose the problem, and when to replace the valve.

Table of Contents

Toggle1. What Does an Anti-Siphon Valve Do?

Before identifying symptoms, it’s important to understand its function:

Fuel System Anti-Siphon Valve

Prevents fuel theft

Stops reverse flow

Ensures stable one-way fuel delivery

Irrigation Anti-Siphon Valve

Prevents contaminated water from backflowing into clean supply

Uses vacuum-breaker action

Must be installed above all emitters

When the valve becomes clogged, stuck, or damaged, the system starts showing warning signs.

2. Symptoms of a Bad Anti-Siphon Fuel Valve

(For cars, trucks, marine engines, generators, and gas tanks)

If the anti-siphon valve is blocked or malfunctioning, the fuel system will typically show these symptoms:

1) Hard Starting or Failure to Start

A restrictive or stuck valve reduces fuel flow.

The engine may:

Crank longer than usual

Start and stall

Fail to start completely

This is one of the most common symptoms.

2) Engine Hesitation or Surging

The valve may intermittently open and close due to debris or a weak spring.

Symptoms include:

Jerking during acceleration

Uneven throttle response

Sudden loss or return of power

3) Loss of Power at High RPM

If the valve limits flow, the engine starves at high demand.

You may notice:

Poor top-end performance

Inability to reach normal speed

Engine bogging under load

4) Fuel Starvation

A failing valve can cause insufficient fuel delivery.

Signs include:

Stalling while driving

Reduced fuel pressure

Engine misfires

5) Difficulty Refueling

If the anti-siphon device is located at the tank’s filler neck, it may:

Cause pump shutdown

Make refueling slow and difficult

Create overflow or back-spill

6) Unusual Suction or Vacuum in the Tank

A stuck anti-siphon valve combined with a blocked tank vent can create:

Whistling sound when cap is removed

Tank collapsing (rare but severe)

This signals improper flow through the valve.

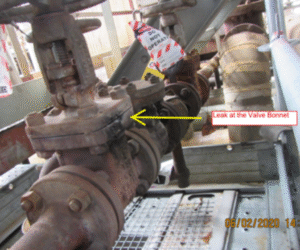

7) Fuel Leak or Strong Fuel Odor

If the valve housing cracks or seals fail:

Fuel can leak under pressure

Odor may appear near tank or fuel line

This is a safety hazard and requires immediate repair.

3. Symptoms of a Bad Anti-Siphon Valve in Irrigation Systems

(For sprinkler systems, hose bibs, and vacuum-breaker valves)

1) Water Leaking or Dripping from the Valve

Damaged seals or internal corrosion can cause:

Constant dripping

Leaks from the anti-siphon vent cap

Often seen when system is pressurized.

2) Sprinkler Zones Not Turning On

A stuck anti-siphon valve prevents flow into the irrigation line.

You may notice:

Weak sprinkler pressure

Zones failing to activate

Uneven spray patterns

3) Water Hammer or Noisy Operation

Internal parts may be loose or worn.

4) Backflow into the Supply Line

If an anti-siphon valve fails completely, it may stop providing backflow protection—posing a contamination risk.

5) Constant Water Flow Even When Turned Off

A damaged plunger or diaphragm can keep the valve stuck open.

4. What Causes an Anti-Siphon Valve to Fail?

Fuel Systems

Debris or dirt in fuel

Corrosion

Weak or broken internal spring

Ethanol-related material degradation

Incorrect installation

Irrigation Systems

Mineral buildup

Freeze damage

UV exposure (for cheap plastics)

High-pressure water surges

Aging seals and diaphragms

5. How to Diagnose a Failing Anti-Siphon Valve

Fuel System Diagnosis

Check fuel pressure at different RPMs

Inspect valve for clogging or corrosion

Test flow by bypassing the valve temporarily (for diagnosis only)

Listen for clicking or restricted flow

Irrigation System Diagnosis

Turn system on zone-by-zone

Check for leaks or flow restriction

Inspect vacuum breaker function

Replace the top assembly to test diaphragm condition

6. When to Replace the Valve

You should replace the anti-siphon valve if:

Internal parts are corroded or stuck

Fuel flow is restricted

The valve leaks or produces strong odor

It no longer provides backflow protection

It repeatedly causes system performance issues

Most valves are not serviceable — replacement is the safest option.

7. Conclusion

A bad anti-siphon valve can cause:

Hard starting

Fuel starvation

Weak irrigation pressure

Leaks

System failure

Recognizing the symptoms early prevents costly damage and ensures the safety and efficiency of your fuel or water system.