As the global energy transition accelerates, hydrogen production, storage, and transportation present unprecedented challenges to fluid control equipment. Due to its unique physical properties—extremely small molecular size and high diffusivity—hydrogen can cause conventional industrial valves to fail through a phenomenon known as Hydrogen Embrittlement.

As a specialized provider of fluid control solutions, we have engineered a dedicated range of valves for the hydrogen supply chain. Our designs align with ASME B31.12 and high-pressure gas standards to ensure maximum safety and operational reliability.

Table of Contents

Toggle1. The Core Challenge: Mitigating Hydrogen Embrittlement

The greatest risk in hydrogen service is the infiltration of hydrogen atoms into the metal lattice, leading to material degradation and sudden brittle fracture.

Material Selection: We strictly utilize high-grade 316/316L Austenitic Stainless Steel. Our material specifications prioritize a high Nickel Equivalent (typically $\ge 12\%$), which ensures the austenitic stability required to resist hydrogen-induced cracking.

Full Traceability: Every valve intended for hydrogen service is accompanied by a Material Test Report (MTR). We verify the chemical composition of every batch to ensure it meets the rigorous demands of hydrogen environments.

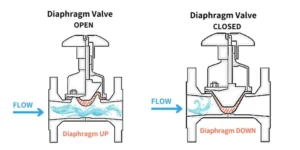

2. Sealing Technology: Achieving Molecular-Level “Zero Leakage”

Hydrogen is the smallest molecule in the universe, capable of escaping through microscopic defects that would be considered “tight” in water or air systems.

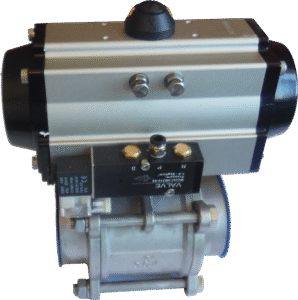

Ultra-Precision Machining: For our Hydrogen Ball Valves, the ball surface is machined to a finish of Ra 0.2µm or better. This mirror-polish finish ensures a perfect interface with the seat, eliminating leak paths.

Advanced Seat Engineering: We utilize high-performance PCTFE or specialized Metal-to-Metal seats. These designs maintain seal integrity across extreme temperature fluctuations (from -40°C to +85°C), common in high-pressure hydrogen refueling cycles.

3. Rigorous Testing: The Helium Leak Test Protocol

Because of the flammable and penetrative nature of hydrogen, standard hydraulic or pneumatic tests are insufficient.

Helium Mass Spectrometry: Every hydrogen gas valve undergoes a Helium Leak Test before leaving our facility. Helium atoms are close in size to hydrogen atoms; passing a helium vacuum or pressure test is the global gold standard for simulating real-world hydrogen integrity.

High-Pressure Cycle Testing: For components used in Hydrogen Refueling Stations (HRS), we perform pressure cycling tests at 35MPa (350 bar) or 70MPa (700 bar) to ensure structural durability under constant pressure swings.

4. Specialized Hydrogen Valve Classifications

Hydrogen Globe Valves

Application: Precise flow regulation or system isolation.

Feature: Designed with multi-layered packing or bellows seals to completely eliminate external fugitive emissions at the valve stem.

Hydrogen Check Valves

Application: Protecting compressors and storage tanks by preventing backflow.

Feature: High-strength spring-loaded design with low cracking pressure, ensuring immediate shut-off even with minimal back-pressure.

Hydrogen Solenoid Valves

Application: Used in Fuel Cell systems and automated dispensing units.

Feature: Explosion-proof (Ex-proof) rated with rapid response times and low power consumption for mobile or stationary hydrogen applications.

5. Why Choose Our Engineering-Led Solutions?

While we continue to evolve with the industry, our value proposition remains rooted in technical compliance:

Standard Alignment: Our products are designed to meet the technical requirements of ISO 19880-3 and ASME B31.12.

Quality Verification: We provide comprehensive documentation, including pressure test certificates and MTRs, for every order.

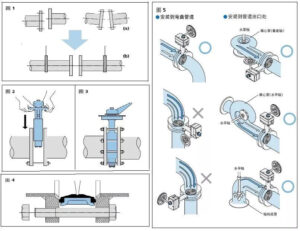

Application Expertise: We provide custom layouts for laboratory hydrogen setups, fuel cell integration, and pilot-scale hydrogen infrastructure.

Conclusion

In the hydrogen economy, safety and reliability are the only metrics that matter. Whether you are building high-pressure storage arrays or precision fuel cell components, we provide the engineered valve solutions necessary for a secure hydrogen future.