Understanding the different types of water valves is fundamental to any plumbing or fluid control system. Whether you are dealing with a residential water line, an industrial piping network, or complex machinery, the valves you select dictate the flow, pressure, and safety of the entire operation.

This definitive guide breaks down the essential plumbing water valve types based on their core function and mechanical design, ensuring you select the right device for isolation, regulation, or backflow prevention.

Table of Contents

ToggleI. Isolation Valves: The ON/OFF Controllers (Shut Off Service)

Isolation valves (or Shut Off Valves) are the most common water valve types used to start or stop the flow of fluid completely. They are designed for ON or OFF service and must not be used for throttling (regulating flow), as this can quickly damage the internal components.

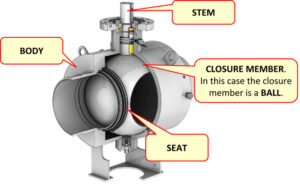

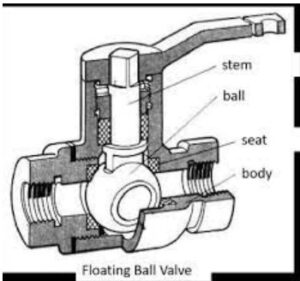

A. Ball Valve (The Modern Standard)

Definition: A quarter-turn valve that uses a revolving ball with a hole through the center to quickly start or stop flow.

| Feature | Description |

| Mechanism | Uses a spherical ball with a hole through the center. A 90° (quarter-turn) rotation is required for full open/close. |

| Advantages | Fast operation; excellent sealing; very low pressure drop; high durability. |

| Common Use | Main water shut off valve in modern homes; general industrial process lines. |

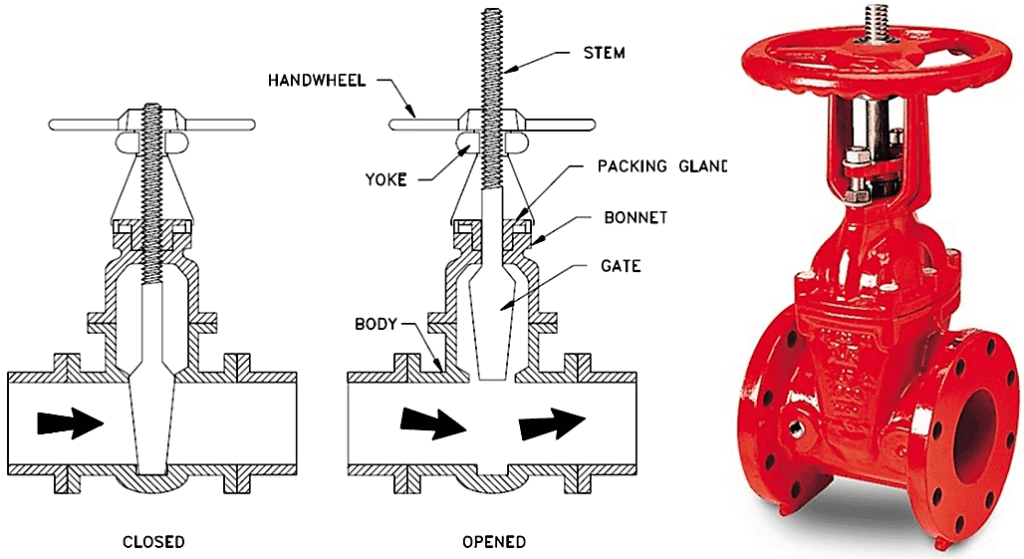

B. Gate Valve (The Traditional Workhorse)

Definition: A multi-turn valve that uses a flat gate or wedge moving perpendicular to the flow path to block the pipe.

| Feature | Description |

| Mechanism | Uses a flat gate or wedge that moves perpendicular to the flow to block the pipe. |

| Advantages | Provides full, unobstructed flow when fully open (very low pressure drop). |

| Disadvantages | Slow to operate (multi-turn); seals can be damaged if used for throttling; prone to leakage over time. |

| Common Use | Older plumbing systems; large pipelines where infrequent isolation is needed. |

II. Regulation Valves: Throttling and Flow Control

Regulation valves are specifically designed to control (throttle) the flow rate or pressure of the fluid. They can be safely operated in a partially open position.

A. Globe Valve (The Throttling Expert)

Definition: A valve that uses a movable disc perpendicular to the flow stream to create a variable restriction, ideal for precise flow regulation.

| Feature | Description |

| Mechanism | Uses a movable disc that seats into an opening parallel to the flow path. The flow path changes direction multiple times. |

| Advantages | Excellent throttling capability; very durable under high cycle use. |

| Disadvantages | High pressure drop due to the turbulent, zig-zag flow path inside the body. |

| Common Use | Steam lines, boiler feed water, and systems requiring precise flow control. |

B. Needle Valve (The Precision Tuner)

| Feature | Description |

| Mechanism | Uses a long, tapered needle instead of a disc to provide extremely fine control over the flow area. |

| Advantages | Extremely precise flow control, especially in small-diameter pipelines. |

| Common Use | Instrumentation lines, chemical dosing systems, and laboratory setups. |

III. Check Valves: Non-Return Safety Mechanisms

Check Valves (or Non-Return Valves) are passive devices that prevent fluid from flowing backward in the pipeline (backflow). They operate automatically based on pressure differential.

A. Swing Check Valve

| Feature | Description |

| Mechanism | Uses a hinged disc (swinging gate) that remains open under normal flow and slams shut if the flow reverses. |

| Advantages | Low pressure drop; ideal for large-diameter lines and liquids. |

| Common Use | Main pump discharge lines and sewage systems. |

B. Lift Check Valve

| Feature | Description |

| Mechanism | Uses a disc that lifts off the seat when pressure is established and drops back onto the seat when flow reverses. |

| Advantages | Better for vertical lines; better sealing in high-pressure systems than swing checks. |

| Common Use | Air, gas, or steam lines; small horizontal liquid lines. |

IV. Specialty and Automation Water Valves

These water valves types address specific safety, pressure, and operational needs.

| Valve Type | Primary Function | Relevant Use Case |

| Pressure Reducing Valve (PRV) | Safety: Automatically reduces high incoming pressure to a safe, constant lower pressure for home use. | Residential water entry points. |

| Relief Valve | Safety: Automatically opens to vent fluid when pressure exceeds a pre-set limit, preventing pipe or tank rupture. | Water heaters, boilers. |

| Automatic Shut-Off Valve | Automation: Uses sensors (flow or moisture) to automatically close the main water line when a leak is detected. | Smart home leak protection. |

V. Expert Guidance: Choosing the Right Valve

Selecting the correct water valve types plumbing depends entirely on the application. Use this quick guide for decision-making:

| Requirement | Best Valve Type | Why? |

| Quick Isolation (ON/OFF) | Ball Valve | Quarter-turn operation and reliable seal. |

| Low Pressure Loss | Gate Valve or Ball Valve | Both provide a full-port flow path. |

| Flow Control/Throttling | Globe Valve | Designed specifically for variable flow restriction. |

| Prevent Backflow | Check Valve | Automated, passive operation. |

VI. Frequently Asked Questions (FAQ)

Q: Which valve is best for the main water shut off?

A: The Ball Valve is the best choice for the main water shut-off. Its quarter-turn design allows for quick identification (ON/OFF) and reliable sealing, which is essential for home emergency isolation.

Q: Why do plumbing gate valves often fail?

A: Gate valves are generally robust, but their failure is often due to infrequent use. When left untouched for years, mineral deposits prevent the gate from fully closing, or the seals crack, leading to leaks when they are finally operated.

Q: Are plastic water valve types reliable?

A: Yes, plastic water valve types (PVC or CPVC) are very reliable and are the standard choice for non-pressure irrigation and drainage systems. However, metal valves (Brass or Bronze) are required for high-pressure, high-temperature, or main-line potable water systems.