If you own a tank-style water heater, regular maintenance—specifically flushing—is critical to maximizing its lifespan and efficiency. However, the factory-installed drain valves often turn this simple task into a frustrating, clogged mess.

This guide explains why the standard valve fails and details why upgrading to a Full Port Ball Valve is the best solution for reliable water heater drainage.

Table of Contents

Toggle1. The Problem with Standard Drain Valves

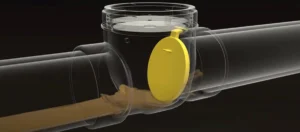

Most water heaters come equipped with one of two types of basic drain valves:

Plastic Drain Valves: These are often fragile, prone to breaking, and easily stripped. They rarely last the lifetime of the unit.

Brass Gate/Spigot Valves: While more durable than plastic, these use a spindle or gate mechanism that creates a narrow, restricted flow path.

The Fatal Flaw: Both standard types feature a Reduced Port that is significantly smaller than the sediment and scale (mineral deposits) that accumulate at the bottom of the tank. When you open the valve, large pieces of scale block the flow, preventing a proper, complete flush.

2. The Solution: The Full Port Ball Valve Advantage

The Full Port Ball Valve solves the clogging issue entirely, transforming tank flushing from a struggle into a simple, quick chore.

A. Unrestricted Flow and Speed

The term “Full Port” means the internal bore of the valve is the same size as the connecting pipe (typically 3/4 inch on residential water heaters). This creates an unobstructed path, allowing sediment, scale, and mineral buildup to pass through freely.

B. Quick, Quarter-Turn Operation

Unlike multi-turn spigot valves that require many rotations to open, a ball valve provides instant on/off control with a simple 90-degree turn of the lever handle. This speeds up the maintenance process dramatically.

C. Superior Longevity

A properly constructed ball valve has fewer internal moving parts exposed to the abrasive sediment compared to a gate valve, ensuring years of reliable use.

3. Choosing the Right Valve: Key Selection Criteria

When selecting a replacement for your water heater drain valve, focus on these two crucial factors:

| Selection Criteria | Recommendation | Why It Matters |

| Size | 3/4 inch NPT | This is the standardized size for nearly all residential water heater drain outlets. |

| Material | Brass or Bronze | Brass water heater drain valves offer superior durability, resist corrosion better than standard alloys, and handle the required operating temperature and pressure without failure. |

Note on Safety: Always ensure your replacement valve is rated for at least 150 PSI WOG (Water, Oil, Gas) and suitable for hot water temperatures.

4. Step-by-Step Guide: Replacing Your Drain Valve

Upgrading your drain valve is a straightforward DIY task that maximizes your water heater’s efficiency.

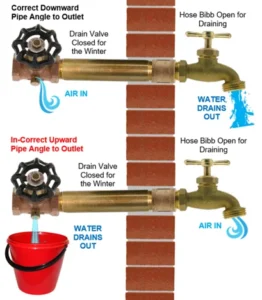

Safety First: Turn off the power (or gas supply) to the water heater and shut off the main cold water supply line to the tank.

Drain the Tank: Attach a hose to the existing drain valve and partially drain the tank to below the level of the drain connection.

Remove Old Valve: Use a wrench to unscrew the old valve. Be prepared for some residual water to spill out.

Prepare the New Valve: Apply Teflon tape or pipe sealant to the male threads of the new Full Port Ball Valve.

Install: Thread the new 3/4 inch brass full port ball valve firmly into the drain port.

Test: Open the cold water supply, repressurize the tank, and check for leaks.

By replacing your restrictive original valve with a robust, full port ball valve, you ensure your tank can be fully and quickly flushed, extending its service life and maintaining heating efficiency.

[CALL TO ACTION: Ready to upgrade? View our selection of 3/4″ Brass Full Port Drain Valves now!]