Table of Contents

ToggleUnderstanding the Valve’s Top Cover

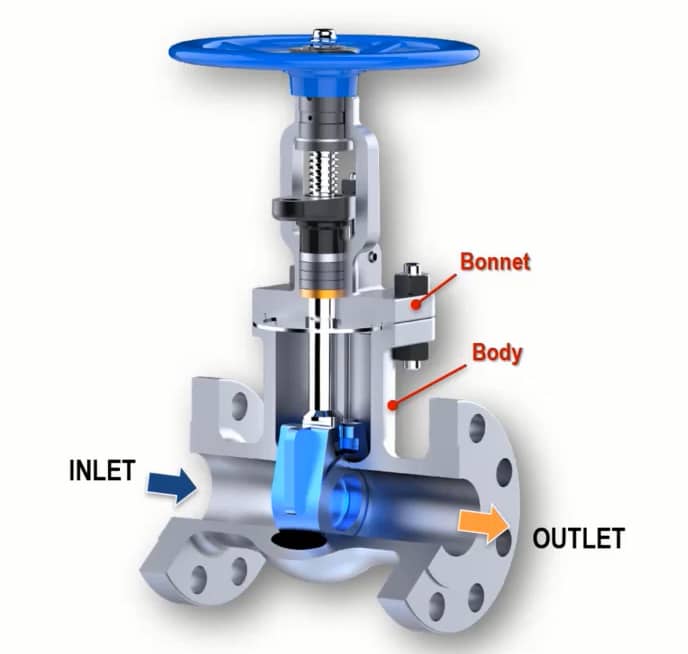

While the valve body contains the flow, the valve bonnet is the essential component that forms a pressure boundary for the upper half of the valve. It is securely attached to the valve body and serves multiple critical functions:

Pressure Containment: It seals the valve body, containing the internal fluid pressure.

Stem Guidance: It houses the valve stem assembly.

Sealing System: It contains the packing material which prevents leakage around the moving stem.

Maintenance Access: It allows access to the internal components (the valve internals) for assembly and maintenance.

Understanding the type of bonnet on a valve is crucial, as the design directly dictates the valve’s pressure capacity and maintenance feasibility.

I. Core Function: What is a Valve Bonnet?

The bonnet is essentially the cover for the valve body opening. In most multi-turn valves (like gate and globe valves), the valve bonnet forms the housing for the stuffing box—the area that holds the packing material used to seal the stem against the surrounding atmosphere.

Key components housed within the bonnet: The packing gland, packing material, packing follower, and sometimes the stem bushing.

Common Search Terms: Whether you call it a bonnet of a valve or simply a valve bonnet, the function remains consistent across all industrial fluid control applications.

II. Primary Bonnet Types: Visualizing Bolted, Welded, and Pressure Seal Designs

Bonnet designs are primarily classified by the method used to secure them to the valve body and maintain the pressure seal. The graphic below illustrates the three primary industrial methods.

Figure 1: Comparison of Primary Industrial Bonnet Joining Methods

1. The Workhorse: Bolted Bonnet

The bolted bonnet valve is the most common design across all industrial valves.

Design: The bonnet is connected to the valve body using a flange arrangement secured by multiple bolts. A gasket (often flat or spiral-wound) is placed between the bonnet and the body to create the pressure seal.

Application: Favored for its ease of disassembly and assembly during maintenance, making it suitable for moderate to high pressures (typically up to ANSI Class 900 or 1500).

2. The Permanent Seal: Welded Bonnet (New/Expanded Content)

The welded bonnet design prioritizes permanent sealing integrity over routine maintenance access.

Design: The bonnet is permanently welded directly to the valve body.

Primary Advantage: Zero potential leak path between the body and bonnet, eliminating the need for a bonnet gasket. This is crucial for applications where any external leakage is unacceptable.

Application: Used for critical, stable, high-temperature service where the media is highly hazardous or where frequent maintenance is not anticipated.

3. The High-Pressure Specialist: Pressure Seal Bonnet

The pressure seal bonnet is specifically designed for the highest pressure and temperature services (ANSI Class 1500 and above).

Design: The seal is created by an internal, unique metal ring gasket (typically wedge-shaped) that is self-energizing.

Working Principle: As the internal pressure increases, the fluid pushes the wedge ring outward, dramatically tightening the seal. The higher the line pressure, the tighter the seal becomes.

Application: Mandatory for power generation, steam lines, and severe hydrocarbon service where maintaining seal integrity at maximum pressure is non-negotiable.

III. Other Important Bonnet Designs and Variations

Beyond the two main types, several other designs address specific operational needs:

| Bonnet Type | Sealing Method | Primary Advantage / Application |

| Screwed Bonnet | Bonnet screws directly into the body threads. | Simple, low-cost. Used for small, low-pressure valves (e.g., small Globe valves). |

| Breech Lock Bonnet | A fast-actuating locking mechanism (similar to a cannon breach). | Used for specialized high-temperature applications; provides ease of dismantling. |

The Extended Bonnet

Another key variant is the extended bonnet. This design vertically separates the stem packing and bonnet from the valve body.

Application: Essential for cryogenic service (extremely low temperatures) or very high-temperature service. The extension creates a thermal barrier, ensuring the packing material remains within a safe operating temperature range to prevent leakage or freezing.

Conclusion: A Vital Pressure Boundary

The bonnet in valve assemblies is far more than just a lid; it is a critical pressure-containing component that enables the valve’s sealing function. The selection of the bonnet type—from the convenient Bolted to the pressure-activated Pressure Seal—is a non-negotiable step in specifying the correct valve for industrial fluid control.

Understanding these valve bonnet types is the first step toward diagnosing issues like a valve bonnet leak and ensuring system safety.