The Y-Strainer is the silent protector of your piping system. However, it is not a “fit and forget” device. As debris accumulates, a strainer transitions from a protector to a major energy consumer. Waiting until your system completely clogs can result in pump cavitation, decreased heat transfer, or total production downtime.

Knowing when to clean your screen is critical. Beyond scheduled maintenance, you must watch for these 5 critical warning signs.

Table of Contents

Toggle1. The 5 Warning Signs of a Clogged Screen

1. Significant Increase in Differential Pressure (ΔP)

This is the most scientific way to monitor your strainer.

The Red Flag: If the pressure drop across the strainer exceeds 5–10 PSI (0.35–0.7 bar), the screen is severely fouled.

The Consequence: Higher resistance forces your pumps to work harder, directly increasing electricity costs and putting stress on motor bearings.

2. Noticeable Drop in Downstream Flow

If you observe a loss in pressure at spray nozzles or a decrease in cooling efficiency in heat exchangers, the Y-strainer is the primary suspect. A partially blocked screen creates a “bottleneck” that starves downstream equipment.

3. Unusual Pump Noise (Cavitation)

If a strainer is installed on the suction side of a pump, a clogged screen causes cavitation. If you hear a sound like “pumping marbles” or gravel, the pump is being starved of fluid. This will rapidly destroy the pump impeller.

4. Rising System Temperatures

In cooling loops, a clogged filter restricts the flow rate required to carry heat away. If your system is running hotter than usual despite the pump being active, the Y-strainer screen likely needs attention.

5. Weak Flow from the Blow-off Port

When you open the blow-off ball valve to flush the unit, the discharge should be powerful. If the flow is weak or “oozing,” the debris has become compacted. At this stage, simple flushing is no longer effective; the strainer must be opened and manually cleaned.

2. How to Clean a Y-Strainer Safely (Step-by-Step)

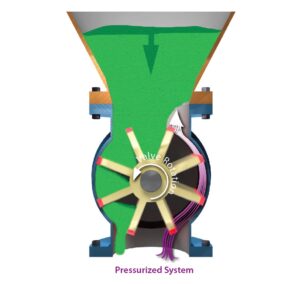

Maintenance on pressurized systems can be dangerous. Follow these industry-standard safety steps to prevent injury:

Step 1: Isolation and Depressurization

NEVER open a strainer under pressure.

Close the isolation valves both upstream and downstream of the strainer.

Open the blow-off valve or a vent plug to ensure the internal pressure is at zero. Verify this with a pressure gauge.

Step 2: Cover Removal

Slowly loosen the bolts on the strainer cap. If fluid starts to spray out, stop immediately and re-verify your isolation.

Remove the cap and the gasket. Expert Tip: Always have a replacement gasket on hand before you start.

Step 3: Screen Inspection

Pull out the stainless steel screen.

What to look for: Check for “collapsing” or tearing. If the mesh is deformed, it means the differential pressure was too high. A damaged screen must be replaced immediately, or debris will bypass the filter.

Step 4: Thorough Cleaning

Use a high-pressure water hose or compressed air. Always spray from the outside in (backwashing) to push particles out of the mesh.

For stubborn scaling (calcium buildup), soak the screen in a mild acidic cleaning solution.

Step 5: Reassembly

Clean the seating surfaces and install a new gasket.

Ensure the screen is properly aligned in the body’s internal seat. If it’s misaligned, fluid will “bypass” the filter.

Cross-tighten the bolts to ensure even pressure on the gasket.

3. Pro Tips to Reduce Maintenance Frequency

Install a Blow-down Ball Valve: Replace the pipe plug with a Full-Port Ball Valve. Opening this valve for 5 seconds once a week can flush out loose debris and extend the time between full teardowns by 50%.

Use a Differential Pressure Gauge: For critical systems, install a gauge that measures pressure before and after the strainer. This removes the guesswork from maintenance.

Keep a Spare Screen: Always stock a spare screen in your warehouse. This allows for an instant swap, so you can clean the fouled screen while the system is back up and running.

Conclusion

A clean Y-strainer ensures an efficient system. By recognizing these 5 signs and following a disciplined safety protocol, you can reduce the risk of unexpected downtime by over 80%.