A check valve is the “one-way street” of your piping system. While its fundamental job is to prevent backflow, there is no “one-size-fits-all” design. From heavy-duty swing check valves used in wastewater to compact dual plate designs in high-rise HVAC systems, each type is engineered to solve a specific mechanical challenge.

Choosing the right type of check valve involves more than just matching pipe size; it requires understanding flow velocity, pressure drop, and the risk of “slamming.” This guide breaks down the four most critical check valve designs to help you select the ideal one for your pump system.

Table of Contents

Toggle1. Swing Check Valve: The High-Flow Standard

The swing check valve is the most widely recognized variety. It features a disc (flap) that swings on a hinge to open or close the flow path.

Design Concept: When the fluid moves forward, it pushes the flap up. When the flow stops, gravity and backpressure swing the flap back onto the seat.

The Advantage: It offers a full, unobstructed flow path, resulting in the lowest pressure drop among all types.

Best Use Case: Large-diameter water and wastewater lines where high flow capacity is the top priority.

2. Dual Plate (Wafer) Check Valve: The Space-Saving Expert

Also known as a butterfly check valve, the dual plate check valve utilizes two spring-loaded half-circle plates.

Design Concept: The two plates fold toward the center during flow and are snapped shut by springs the moment flow decelerates.

The Advantage: Its ultra-thin “Wafer” body makes it 80% lighter than a swing check valve. It is much easier to install and requires far less structural support.

Best Use Case: High-rise buildings, HVAC systems, and oil & gas facilities where space and weight are at a premium.

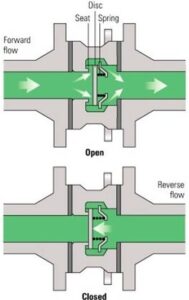

3. Silent (Non-Slam) Check Valve: The Precision Protector

Unlike other types that rely solely on gravity or backflow to close, the silent check valve is proactive.

Design Concept: It uses a center-guided disc and a high-tension spring. The spring is designed to close the valve before the flow can actually reverse direction.

The Advantage: It eliminates “Valve Slam” and the resulting water hammer. It is the most reliable way to protect sensitive pumps and instrumentation.

Best Use Case: Variable Frequency Drive (VFD) pump stations and high-pressure water transmission lines.

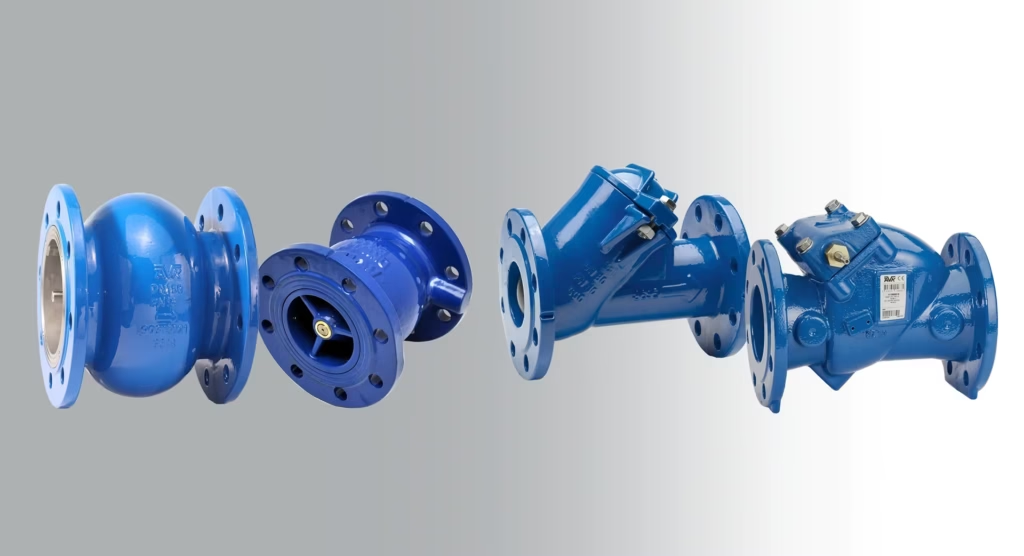

4. Lift Check Valve: The High-Pressure Specialist

A lift check valve shares its internal body shape with a globe valve, where a piston or ball “lifts” off the seat to allow flow.

Design Concept: The disc is guided vertically. Flow enters from under the seat, lifting the disc. Gravity or a spring returns it to the seat when flow ceases.

The Advantage: It offers superior sealing at high pressures and is very robust against wear.

Best Use Case: High-pressure steam, air, or gas systems where tight shutoff is mandatory.

5. Summary Comparison: Choosing the Right Type

| Check Valve Type | Best For… | Pressure Drop | Closing Speed |

| Swing Check | Maximum flow, low pressure | Low | Slow (Risk of slam) |

| Dual Plate | Compact spaces, lightweight | Moderate | Fast (Spring-assisted) |

| Silent Check | Protecting pumps, zero noise | Moderate/High | Fastest (Pre-emptive) |

| Lift Check | High-pressure steam/air | High | Moderate |

Conclusion

Each type of check valve has its trade-offs. If you prioritize low energy loss, a swing check is your best bet. If you are protecting an expensive pump from slamming, a silent check valve is the necessary investment. Understanding these mechanical differences ensures your system operates smoothly without the risk of backflow damage.