Table of Contents

Toggle1. Introduction: What Is Valve Trim?

Valve trim refers to all internal parts of a valve that come into direct contact with the fluid and control the flow. These components determine the valve’s performance, flow characteristics, sealing, and resistance to corrosion or erosion.

1.1 Valve Trim Definition

In valve engineering, valve trim includes the following parts:

Plug / Disc / Ball / Gate

Seat or seat ring

Stem

Backseat

Sleeve or guide bushings

Gaskets and packing (sometimes included depending on standard)

Trim = All wetted, functional, and replaceable parts controlling flow.

1.2 Why Valve Trim Matters

Valve trim determines:

Flow control accuracy

Shutoff capability

Chemical compatibility

Resistance to erosion, corrosion, cavitation

Safety performance

Valve lifespan

Trim selection is critical for:

Oil & gas

Chemical & petrochemical

Refining

Power generation

Water and wastewater

Marine and offshore

2. What Components Are Included in Valve Trim?

(Full technical explanation)

2.1 Gate Valve Trim

Includes:

Wedge / gate

Seats

Stem

Backseat bushing

Seat ring

2.2 Globe Valve Trim

Disc (plug)

Seat ring

Stem

Cage (control valve)

2.3 Ball Valve Trim

Ball

Seats (soft or metal)

Stem

2.4 Control Valve Trim

The most complex:

Plug

Seat

Stem

Cage

Guides

Seals

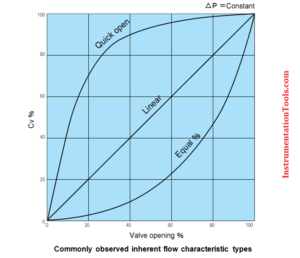

Characterization elements (equal %, linear)

Includes Cavitation-resistant trims:

Multi-hole cage trim

Multi-stage trim

Anti-cavitation trim

Noise-reduction trim

3. Valve Trim Material Overview

Valve trim uses different material classes:

3.1 Stainless Steels (Trim 8, Trim 5, etc.)

304

316

316 + HF

Stellite hardfacing

3.2 Carbon Steels

A105

410 SS faced

HF coatings

3.3 Hardfacing Alloys

Used for severe service:

Stellite 6

Alloy 6

Tungsten carbide

Colmonoy

Chromium carbide

3.4 Special Alloys

Monel

Inconel

Hastelloy

Duplex / Super Duplex

Titanium

3.5 Soft Trim Materials (control valves)

PTFE

RPTFE

EPDM

Viton

PEEK

Delrin

4. API Valve Trim Chart (FULL)

✔ Covers API 600, 602, 603, 608

✔ Includes Trim Numbers 1–16

✔ Includes materials & applications

✔ High-value SEO section

# 5. Full API Valve Trim Chart (API 600, API 602, API 603, API 608)

The most complete API valve trim chart available online.

This chart lists all commonly used API valve trim numbers, materials, and recommended applications.

5.1 API Trim Chart (Master Table)

✔ Covers Trim Numbers 1–16

✔ Includes Material, Hardfacing, Seat Type, and Applications

✔ Ideal for SEO & Engineering Reference

API Valve Trim Chart (Full Table)

| Trim No. | Stem / Disc / Gate Material | Seat / Seat Ring Material | Hardfacing / Overlay | Typical Use |

|---|---|---|---|---|

| Trim 1 | 410 SS | 410 SS | None | Clean water, steam, general service |

| Trim 2 | 304 SS | 304 SS | None | Corrosion-resistant services |

| Trim 3 | 304 SS | 410 SS | None | Mixed services, moderate corrosion |

| Trim 4 | 410 SS | 304 SS | None | Corrosive water, mild chemicals |

| Trim 5 | 410 SS | 410 SS HF | Stellite (CoCr alloy) | Erosion, high temp, steam (MOST COMMON HARD TRIM) |

| Trim 6 | 410 SS | 410 SS | 410 + HF on seating | Upgraded wear resistance |

| Trim 7 | 410 SS | 316 SS | None | Chlorides, moderate corrosion |

| Trim 8 | 316 SS | 316 SS | None | Chemical service (MOST COMMON SS TRIM) |

| Trim 9 | Monel | Monel | None | Sea water, H₂S, sour gas |

| Trim 10 | 316 SS | 316 SS HF | Stellite overlay | Severe corrosion + high temp |

| Trim 11 | Alloy 20 | Alloy 20 | None | Sulfuric acid environments |

| Trim 12 | 316 SS | 316 SS | Stellite seat + hardfaced disc | High cycle, high temp |

| Trim 13 | 316 SS | 316 SS | Stellite both sides | Severe service + erosion |

| Trim 14 | Hastelloy | Hastelloy | None | Strong acids, chlorides |

| Trim 15 | Titanium | Titanium | None | Seawater, brine, high chlorides |

| Trim 16 | Duplex SS | Duplex/Super Duplex | None | Offshore, sour service, high chloride |

5.2 API Trim Quick Summary (Easy Reference)

Most Common API Trims

Trim 1 → Basic service

Trim 5 → Steam, high temp, erosion

Trim 8 → Chemical service

Trim 12 / 13 → Severe service, high erosion

Trim 16 → Offshore & high chlorides

Corrosion-resistant Trims

Trim 8 (316 SS)

Trim 9 (Monel)

Trim 14 (Hastelloy)

Trim 15 (Titanium)

Hardfaced Trims

Trim 5

Trim 10

Trim 12

Trim 13

These are used when erosion or high temperatures are expected.

# 6. Trim 5 vs Trim 8 (Important Comparison Section)

| Feature | Trim 5 | Trim 8 |

|---|---|---|

| Material | 410 SS + Stellite | 316 SS |

| Corrosion Resistance | Moderate | High |

| Temperature Resistance | Excellent | Good |

| Erosion Resistance | Excellent | Moderate |

| Steam Service | ✔ Recommended | ✘ Not recommended |

| Chemical Service | ✘ Limited | ✔ Recommended |

| Typical Use | Steam, gas, high temp | Water treatment, chemicals |

Which one should you choose?

High temperature, steam, erosion → Trim 5

Chemical service, chlorides, acidic environments → Trim 8

# 7. API 600 / API 602 Trim Chart (Simplified)

API 600 (Gate / Globe / Check Valves)

Most used trims:

| API 600 Trim | Description |

|---|---|

| Trim 1 | 410 SS basic service |

| Trim 5 | 410 SS + Stellite seat (high temp) |

| Trim 8 | 316 SS (chemical) |

| Trim 12 | 316 SS + HF seat (high pressure/high temp) |

| Trim 16 | Duplex/Super Duplex |

API 602 (Small Forged Steel Valves)

Common trims:

| API 602 Trim | Description |

|---|---|

| Trim 1 | 410 SS |

| Trim 5 | Stellite faced |

| Trim 8 | 316 SS |

| Trim 9 | Monel for sour service |

| Trim 16 | Duplex |

# 8. NACE Valve Trim Chart (MR0175 / ISO 15156)

NACE-Compliant Trims

Used for sour gas (H₂S) applications.

| Trim No. | NACE? | Comments |

|---|---|---|

| Trim 1 (410 SS) | ❌ No (unless special treatment) | Can suffer SSC |

| Trim 8 (316 SS) | ✔ Yes | Very common |

| Trim 9 (Monel) | ✔ Yes | Excellent sour service |

| Trim 14 (Hastelloy) | ✔ Yes | Severe H₂S, chlorides |

| Trim 16 (Duplex) | ✔ Yes | High strength + chloride resistance |

Most used NACE trim:

→ Trim 8 (316 SS) and Trim 9 (Monel)

# 9. Valve Trim Types (Full Classification)

This section covers the keyword cluster:

valve trim types

control valve trim

valve trim material types

9.1 By Material

Carbon steel trims

Stainless steel trims

Alloy trims

Hardfaced trims

Soft seat trims

Elastomer trims

9.2 By Service Type

Standard trim

Corrosion-resistant trim

Erosion-resistant trim

High-temperature trim

Cryogenic trim

NACE sour gas trim

9.3 In Control Valves

Cage-guided trim

Multi-stage trim (anti-cavitation)

Noise-reducing trim

Quick-change trim

Characterized trim (equal %, linear, modified linear)

10. Valve Trim Material Selection Guide (How to Choose the Right Trim)

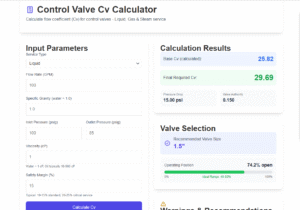

Selecting the correct valve trim material determines whether a valve lasts 30 years or fails in 3 months. The wrong trim leads to leakage, galling, corrosion, erosion, or complete failure.

Below is a step-by-step material selection guide used by engineers.

Step 1 — Define the Fluid Type

Material compatibility is the first filter.

✔ Compatible With Most Fluids

304, 316 stainless steel

Monel

Hastelloy B/C

Bronze

✔ For Corrosive / Chloride / Sour Service

316 SS

316+Hardfacing

Duplex / Super Duplex

Hastelloy C276

Monel 400

Inconel 625

✔ For Hydrocarbon / Steam

410 SS (hardened)

13Cr

Stellite hardfacing

Step 2 — Identify Temperature Range

| Temperature | Recommended Trim Materials |

|---|---|

| -20°C to 200°C | 304, 316 SS, Bronze |

| 200°C–400°C | 410 SS, 13Cr, Stellite |

| 400°C–600°C | Stellite, Inconel |

| > 600°C | Inconel 718, Stellite |

Step 3 — Consider Pressure & Velocity (Erosion Risk)

High velocity or flashing → erosion-resistant trim.

Best choices:

Stellite 6

Tungsten carbide

410 SS hardened

Inconel / Monel

Avoid bronze or soft stainless steels in erosive media.

Step 4 — Check Need for Hardfacing / Anti-Galling

Galling often occurs in stainless-on-stainless trim.

Use:

Stellite facing

Nitrided surfaces

Hardened 410 SS

Step 5 — Sour Service (H₂S) Requirements – NACE MR0175 Compatibility

✔ Monel

✔ Inconel

✔ Hastelloy

✔ Duplex / Super Duplex

✔ Stellite

✘ 410 SS (only limited use unless specially heat treated)

✘ 13Cr (risk of SSC)

For sour applications, always verify:

Hardness limits

SSC resistance

Sulfide cracking compliance

11. Valve Trim Types (Based on Function)

A. Control Valve Trim Types

Cage-guided trim – stable, low vibration

Plug & seat trim – common for throttling

Multi-hole / Anti-cavitation trim – eliminates noise and flashing

Equal percentage / linear trim – flow characteristic options

B. On–Off Valve Trim Types

Wedge gate trim

Globe plug trim

Ball valve seats & ball trims

Butterfly valve discs

12. API Trim 1–17 Explained (Material Overview)

You have the full chart earlier—this section gives real-world use cases.

Trim 1 – 410 SS

Best for:

Water

Steam

General hydrocarbons

Moderate temp applications

Avoid:

Chlorides (pitting)

Sour service

Trim 5 – 410 SS + Stellite

Best for:

High-temperature valves

Steam service

Anti-galling, high wear applications

Common in:

Refinery isolation valves

Power plants

High-cycle globe valves

Trim 8 – 316 SS

Best for:

Corrosive fluids

Chemical plants

Moderate chlorides

Avoid:

High-cycle erosion

Cavitation

Trim 10 – Monel 400

Best for:

Brine

Saltwater

Sour gas

Excellent chloride resistance.

Trim 12 – 316 SS + Hardfacing

Best for:

Corrosive + erosive service

Offshore

Chemical injection lines

Trim 13 – Alloy 20

Best for:

Sulfuric acid

Highly acidic service

Severe corrosion environments

Trim 16 – Hastelloy C

Best for:

Corrosive + high temp

Chlorine, seawater

Chemical reactors

Trim 17 – Stellite

Best for:

Extreme erosion

High temperature

Severe throttling

Cavitation control

Most durable trim material.

13. Valve Trim Number System (How to Read It)

The “trim number” defines:

Stem material

Plug/disc material

Seat material

Hardfacing type

Facing material

This ensures standardization across manufacturers:

API 600 (gate valves)

API 602 (compact gates/globes)

API 603 (corrosion-resistant valves)

Important: Trim number ≠ body material.

Trim only refers to internal wetted moving parts.

14. Control Valve Trim (Special Features)

Control valve trim includes:

Seat ring

Plug

Stem

Guide bushings

Cage (optional)

Anti-cavitation elements

Different control trim designs:

Single-stage

Multi-stage

Multi-hole cage

Low-noise trim

Anti-flashing trim

15. Gate Valve Trim Chart (API 600 Focus)

Common gate valve trim selections:

| API Trim | Gate Valve Application |

|---|---|

| Trim 1 | Water, steam |

| Trim 5 | Steam, refinery |

| Trim 8 | Corrosive chemicals |

| Trim 10 | Seawater, sour service |

| Trim 12 | Corrosive + erosive fluids |

16. Valve Body Material vs Valve Trim (Don’t Confuse Them)

Valve body material = main pressure boundary

Trim material = internal sealing & moving parts

Common combination examples:

| Body Material | Typical Trim |

|---|---|

| WCB | Trim 1, 5 |

| CF8M | Trim 8, 12 |

| Duplex | Trim 12, 16 |

| Bronze | Trim 1, 8 |

17. FAQs

1. What is valve trim?

All internal wetted parts that control, shut off, or regulate flow.

2. Does body material determine trim?

No — trim is chosen based on fluid, temperature, and pressure.

3. Is Stellite the best trim?

Yes for:

High temp

Severe erosion

High cycle service

But not needed for simple water or low-pressure service.

4. What is the difference between Trim 5 and Trim 8?

Trim 5 = 410 SS + Stellite (strong, good for steam)

Trim 8 = 316 SS (corrosion resistance)

5. What trim is best for seawater?

Monel (Trim 10)

or

Duplex + Stellite (Custom trims)