Table of Contents

ToggleThe Language of Welding

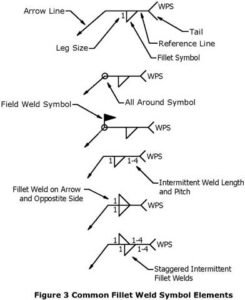

In the world of piping and valve manufacturing, communication between the designer and the welder is conducted through welding symbols. These standardized symbols, defined by authorities like AWS (American Welding Society) or ISO, convey complex instructions—such as weld type, size, and finish—within a simple graphic.

Accurately reading a butt weld symbol or a socket weld symbol is essential to ensuring the structural integrity and safety of a pressure system.

I. The Anatomy of a Welding Symbol

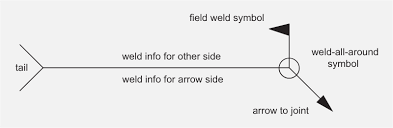

Every standard welding symbol consists of three basic parts:

The Reference Line: The horizontal line that serves as the foundation.

The Arrow: Points to the joint where the weld is to be performed.

The Weld Symbol: The specific graphic representing the type of weld (placed above or below the reference line).

II. Primary Pipe Weld Symbols and Their Meanings

1. Butt Weld Symbols (Groove Welds)

A butt weld is a groove weld. Depending on how the pipe ends are prepared (beveled), the symbol will change.

Square Butt Weld Symbol: Represented by two parallel vertical lines. This indicates that the pipe ends are flat and not beveled.

V-Groove Butt Weld Symbol: The most common butt welding symbol for pipes. It looks like a “V,” indicating the ends are beveled to create a “V” shape for the weld pool.

Butt Joint Weld Symbol: Often used interchangeably with groove symbols to describe the overall edge-to-edge connection.

2. Socket Weld Symbols (Fillet Welds)

This is where many beginners get confused. Even though it is a socket weld connection, the actual weld performed is a fillet weld.

Socket Weld Symbol: It is represented by a Right Triangle. The vertical leg of the triangle is always on the left side of the symbol.

Placement: If the triangle is below the reference line, the weld is on the “arrow side.” If above, it is on the “other side.”

III. Common Symbols Quick Reference Table

| Weld Type | Graphic Symbol | Meaning on Drawing |

| Butt Weld (V-Groove) | V | Beveled pipe ends joined edge-to-edge. |

| Square Butt Weld | | | | Flat pipe ends joined edge-to-edge. |

| Socket Weld | ⊿ | Pipe inserted into a socket and fillet welded. |

| Fillet Weld | ⊿ | A weld of approximately triangular cross-section. |

IV. Critical “Site” vs. “Shop” Symbols

When reviewing weld symbols for pipe systems, look for the “Flag” and “Circle”:

The Flag (Field Weld): A small flag at the junction of the arrow and reference line means the weld should be performed at the installation site, not in the factory.

The Circle (Weld-All-Around): A circle at the junction indicates the weld must be continuous around the entire circumference of the pipe—standard for almost all socket welded or butt welded joints.

V. Why Accuracy Matters

Misinterpreting a butt weld vs fillet weld symbol can lead to catastrophic failures. For instance, a butt weld provides full penetration for high-pressure service, whereas a fillet weld (used in socket welding) only provides surface-level strength. Choosing the wrong weld types during the design phase or misreading them on the shop floor compromises the safety of the entire valve assembly.

Conclusion

Mastering piping welding symbols is a fundamental skill for any piping professional. Whether you are looking for a butt weld symbol to specify a high-pressure line or a socket welding symbol for a small-bore utility line, these graphics ensure that the finished product meets the engineering intent.