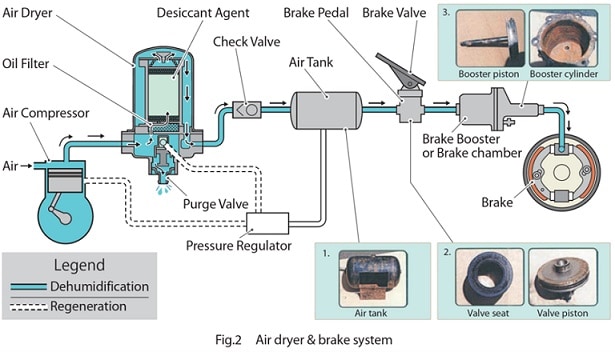

In a heavy-duty truck, the treadle valve (air brake foot valve) is the primary interface between the driver and the stopping power of the vehicle. Unlike a passenger car’s hydraulic master cylinder, this valve is a sophisticated air-pressure regulator.

Understanding how the air brake foot valve diagram translates to real-world braking is essential for any technician or fleet owner. In this guide, we break down the internal mechanics of the dual brake valve and how it ensures safety even in the event of a system failure.

Table of Contents

Toggle1. What is a Treadle Valve?

The treadle valve is a foot-operated, graduated pressure-control valve. Its job is to take high-pressure air from the primary and secondary reservoirs and deliver a metered amount of that air to the brake chambers. The more you “tread” (push) on the pedal, the higher the air pressure delivered to the brakes.

2. The Dual Circuit Safety System

Modern trucks utilize a dual brake valve diagram design. This is a federal safety requirement. The valve is split into two independent sections:

Primary Circuit (Rear Brakes): Usually supplied by the rear air tank.

Secondary Circuit (Front Brakes): Usually supplied by the front air tank.

Why Dual Circuits? If a hose bursts in the front brake system (Secondary), the dual brake valve ensures the Primary circuit still functions, allowing the driver to stop the truck using the rear brakes. The two sections are mechanically linked so that one pedal stroke operates both simultaneously.

3. Technical Air Brake Foot Valve Diagram: Port Identification

When looking at an air brake/foot valve diagram, you will notice specific numbers assigned to the ports. These follow international standards (usually Bendix or Bosch):

| Port Number | Port Type | Function |

| 11 & 12 | Supply Ports | Connected directly to the Primary and Secondary air tanks. |

| 21 & 22 | Delivery Ports | Sends the metered air signal to the relay valves or brake chambers. |

| 3 | Exhaust Port | Located at the bottom; releases air to the atmosphere when you lift your foot. |

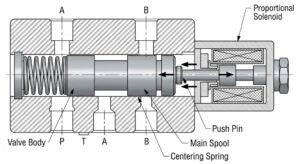

4. Internal Components: How It Works

The magic of the treadle valve happens inside the casting. A standard valve consists of:

The Plunger: The rod that moves down when you step on the pedal.

Graduating Springs: These provide the “feel” of the pedal. They allow the driver to apply 10 PSI for a slow stop or 100 PSI for an emergency.

Inlet/Exhaust Valve Poppets: These rubber-faced discs open to let air in and close to seal the system.

O-Rings and Seals: These maintain the airtight integrity between the primary and secondary circuits.

5. The Working Principle: A 3-Stage Process

Applying: As you push the pedal, the plunger forces the internal poppets off their seats. Air flows from Supply (11/12) to Delivery (21/22).

Lapping (Holding): Once the desired pressure is reached in the brake lines, the internal springs balance the air pressure, and the valve “laps” (closes both ports) to hold that specific pressure steady.

Releasing: When you lift your foot, the plunger rises. The delivery air is then exhausted through the Exhaust Port (3) at the bottom of the valve, releasing the brakes.

6. Pro Maintenance: Identifying a “Dual” Failure

If you see a treadle valve diagram showing air leaking between ports 21 and 22, you have a “cross-circuit” leak. This is dangerous because a failure in one air tank could potentially drain the other. If your dash gauges show both needles dropping simultaneously when you hold the brake, your foot valve’s internal seals are compromised.