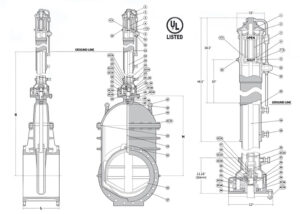

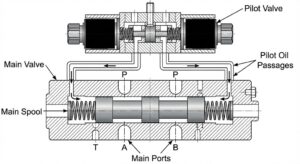

In the world of fluid control, the Gland Packing (also known as stem packing) is a small component with a massive responsibility. A $10 packing ring is often the only thing standing between a smooth-running plant and a catastrophic, costly leak.

Whether you are dealing with high-pressure steam, abrasive slurries, or corrosive chemicals, choosing the right material—and installing it correctly—is critical for extending valve life and reducing maintenance costs. This guide breaks down the essential materials and selection criteria for modern industrial systems.

Table of Contents

Toggle1. How Gland Packing Works: The Science of Sealing

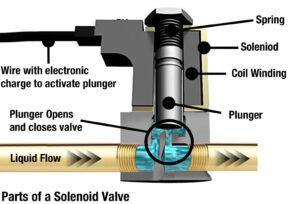

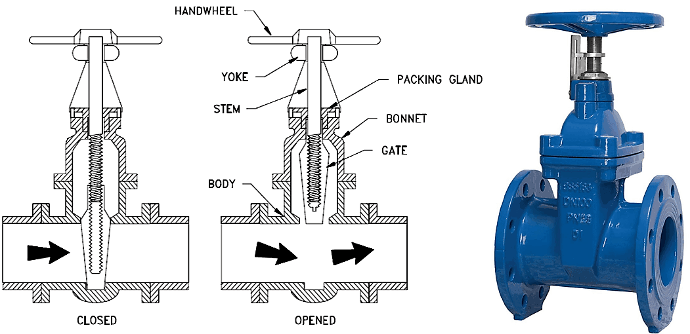

Gland packing operates on a Compressive Sealing Principle. When the gland follower is tightened, it exerts axial pressure on the packing rings, causing them to expand radially against the valve stem and the stuffing box wall.

A high-quality packing must achieve three things:

Low Friction: To allow the stem to move smoothly without burning out the actuator.

Thermal Stability: To resist shrinking or hardening under high temperatures.

Chemical Resistance: To withstand the corrosive nature of the media.

2. Choosing the Right Material (Material Selection Matrix)

Selecting the wrong material is the #1 cause of premature valve failure. Here is a breakdown of the industry’s most reliable fibers.

A. Flexible Graphite (The High-Temp Specialist)

Temperature: Up to 650°C (in non-oxidizing media).

Best For: High-pressure steam, power plants, and oil refineries.

Pro Tip: Look for Wire-Reinforced Graphite (with Inconel or Stainless Steel wire) for high-pressure applications over 250 Bar to prevent “blow-outs.”

B. PTFE / Teflon (The Chemical Champion)

Temperature: Up to 260°C.

Best For: Food & Beverage, Pharma, and aggressive acids/alkalis.

Advantage: Lowest friction coefficient. It is self-lubricating and ensures the stem won’t stick even after long periods of inactivity.

C. Aramid / Kevlar (The Abrasive Warrior)

Temperature: Up to 280°C.

Best For: Slurries, wastewater, and mining.

Advantage: Incredible mechanical strength. If your media contains sand or solid particles that would “chew up” graphite, Aramid is the solution.

D. Synthetic Fiber / Polyester (The Budget Workhorse)

Best For: General utility, water treatment, and low-pressure HVAC.

Advantage: Highly cost-effective for non-critical services.

3. Comparison Table for Quick Selection

| Feature | Flexible Graphite | PTFE (Teflon) | Aramid (Kevlar) |

| Max Temp | ★★★★★ (High) | ★★★ (Medium) | ★★★ (Medium) |

| Chemical Resistance | ★★★★ | ★★★★★ (Excellent) | ★★★★ |

| Wear Resistance | ★★★ | ★★ | ★★★★★ (Superior) |

| Friction | Low | Lowest | Moderate |

| Common Media | Steam, Oil, Gas | Acids, Food, Pharma | Slurries, Paper Pulp |

4. The “No-Asbestos” Standard

In today’s global market, Asbestos packing is obsolete. Due to severe health risks and environmental regulations (REACH/RoHS), we specialize exclusively in Non-Asbestos high-performance fibers. If you are still using asbestos-based materials, we can help you transition to safer, more efficient graphite or synthetic alternatives.

5. Pro Installation Tips: Avoid the 3 Common Mistakes

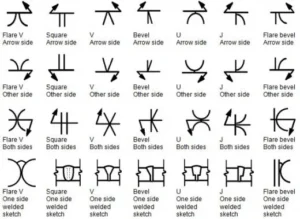

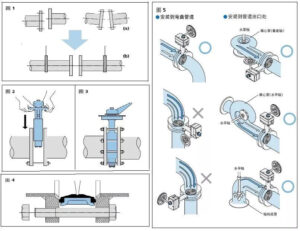

The 45° Angle Cut: Never cut packing rings straight. Always cut at a 45° angle to create a “scarf joint” for a better seal.

Stagger the Joints: When installing multiple rings, stagger the joints by 90 to 120 degrees. Never line up the cuts, or you will create a direct leak path.

Don’t Over-Tighten: Tighten the gland follower just enough to stop the leak. Over-tightening increases friction, creates excessive heat, and leads to “stem scoring” (physical damage to the valve stem).

Conclusion: A Small Investment for Big Protection

Proper gland packing selection is the key to Zero Leakage and Zero Unscheduled Downtime. By matching the fiber material to your specific temperature and chemical environment, you ensure the long-term reliability of your flow control system.