In high-temperature industrial processes, such as those found in power generation, metallurgy, and coal chemistry, the reliable control of hot, abrasive media (like ash, slag, and pulverized coal) is a constant challenge. Conventional valves quickly fail under continuous thermal stress.

The Water-Cooled High-Temperature Knife Gate Valve is engineered specifically to address this critical issue. Capable of handling operating temperatures up to 1000℃, this valve combines advanced material science with active cooling design to ensure precise flow regulation and operational stability in the most punishing environments.

Table of Contents

ToggleI. The Core Technology: How it Withstands 1000℃

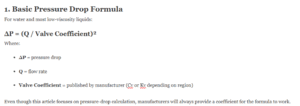

The valve’s exceptional thermal resilience is achieved through a two-pronged engineering approach:

- High-Performance Alloys: Critical components exposed directly to the media utilize super-heat-resistant stainless steel alloys, primarily 310S and 2520. These materials are inherently resistant to high-temperature oxidation and thermal creep, forming the foundation of the valve’s integrity.

- Active Thermal Management (Water-Cooling/Dissipation): To protect the sensitive operational parts—the packing, actuator mechanism, and seals—the design incorporates:

- Extended Valve Stems: To increase the distance and air gap between the hot zone and the bonnet.

- Cooling Fins/Jacket: Strategic placement of cooling fins or a dedicated water-cooling jacket (as implied by the valve’s name) ensures effective heat dissipation, keeping the packing and actuator within safe operating temperatures and preventing seal degradation or stem seizure.

This combination effectively solves the long-standing problem of premature valve failure in extreme heat applications.

II. Functional Excellence: Engineered for Abrasive & Sticky Media

Beyond heat resistance, this valve retains and enhances the knife gate’s renowned capability for handling difficult media:

| Key Functional Feature | Engineering Design | Practical Benefit |

| Non-Clogging Operation | Full-circle, straight-through flow channel. | Prevents media build-up, material settling, and jamming, especially with slurries and powders. |

| Self-Cleaning Action | Gate lifts clear of the seal face; Hard PTFE scraper on the stem. | The gate effectively wipes the seal area clean upon opening, while the scraper prevents dust and grit from entering the stuffing box, boosting gate life. |

| Positive Shear/Cut-Off | Knife-edge beveling at the bottom of the gate. | Provides efficient cutting action through soft or fibrous materials (e.g., pulp, wood chips, fly ash aggregates). |

| Superior Corrosion Resistance | Precision-cast, integral flanged body (Material options: 304, 316L, WCB). | Durable construction that resists chemical attack and abrasive wear from aggressive media. |

III. Simplified Structure, Reduced Maintenance

A key advantage of the knife gate valve over more complex high-temperature alternatives is its design philosophy centered on simplicity and ease of maintenance:

- Compact Structure: The short face-to-face (wafer) design saves raw materials, reduces weight, and minimizes installation space, which is critical in crowded industrial plants.

- Rapid Operation: The design features like double-ended studs and the guided gate block ensure fast, precise, and reliable opening and closing cycles.

- Sealing Integrity: The scientific design of the upper sealing stuffing box guarantees a safe, durable, and effective primary seal over extended use.

IV. Ideal Industrial Applications

This water-cooled high-temperature valve is the preferred control solution for systems that demand stable flow regulation under extreme thermal load:

- Power Generation: Ash and slag handling systems in CFB/BFB boilers and pulverized coal furnaces, where it regulates the volume of hot residue transport to stabilize the furnace’s operating conditions.

- Metallurgy & Smelting: Controlling material flow in high-temperature kilns, ovens, and preparation systems.

- Chemical & Pharmaceutical: Processing systems involving hot, particulate, or abrasive chemicals.

In summary, the Water-Cooled High-Temperature Knife Gate Valve delivers an exceptional blend of high-temperature endurance, reliable material control, and low life-cycle cost, positioning it as the premier solution for severe-service material handling up to 1000℃.

Don’t let extreme heat compromise your process stability. Contact TOT Valve today for a specialized consultation and quote on our high-temperature solutions.