In the industrial valve catalog, WCB is perhaps the most frequent acronym you will encounter. Whether you are browsing for gate valves, check valves, or ball valves, WCB stands as the industry backbone. But what does WCB mean in valves, and why is it the preferred choice for billions of fluid control systems worldwide?

In this guide, we break down the chemical composition, mechanical properties, and application limits of ASTM A216 WCB material.

Table of Contents

Toggle1. What Does WCB Stand For?

In the context of industrial valves, WCB is a grade designation under the ASTM A216 standard. The acronym can be broken down as:

W: Weldable (Specifies that the material can be easily welded during installation or repair).

C: Cast Carbon Steel (Indicates the primary alloy is carbon steel, formed through a casting process).

B: Grade B (Refers to the specific mechanical strength and chemical balance defined by ASTM).

Important Note: While “WCB” can mean “Will Call Back” in texting, in the engineering world, it exclusively refers to Wrought/Weldable Carbon Steel Grade B.

2. Chemical Composition of WCB Material

Engineers search for “what is WCB material” primarily to understand its durability. Under ASTM A216, WCB must adhere to strict chemical limits to ensure weldability and pressure resistance:

| Element | Composition (%) |

| Carbon (C) | 0.30% Max |

| Manganese (Mn) | 1.00% Max |

| Silicon (Si) | 0.60% Max |

| Sulfur (S) | 0.045% Max |

| Phosphorus (P) | 0.040% Max |

Note: For every 0.01% reduction in Carbon, an increase of 0.04% Manganese is allowed, up to a maximum of 1.10%.

3. Mechanical Properties: Why Use WCB for Valve Bodies?

The WCB valve body is favored because it offers an excellent balance between cost, strength, and ease of manufacturing.

Tensile Strength: 70 to 95 ksi (485 to 655 MPa)

Yield Strength: 36 ksi (250 MPa) Minimum

Elongation: 22% Minimum

These properties make material WCB ideal for high-pressure service where extreme corrosion resistance is not required.

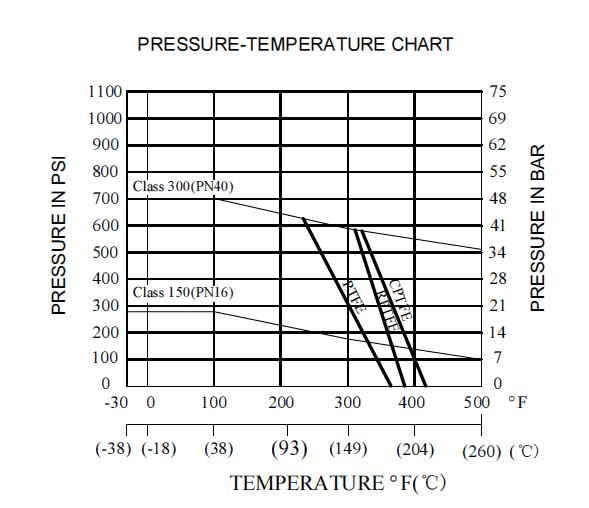

4. Temperature & Application Limits

While WCB is versatile, it has critical thermal boundaries.

Standard Temperature Range: -29°C to 425°C (-20°F to 800°F).

The “Graphitization” Risk: When exposed to temperatures above 425°C for long periods, the carbon in WCB can turn into graphite, making the valve brittle. For higher temperatures, WC6 or WC9 (Alloy Steel) is required.

The “Brittle” Risk: For temperatures below -29°C, WCB loses its impact toughness. In cryogenic or low-temp services, LCB (Low Carbon Steel) is the correct choice.

5. Common WCB Valve Types

Most heavy-duty industrial valves utilize WCB as their primary housing material:

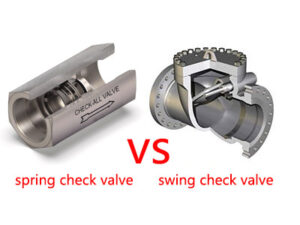

WCB Check Valve

A WCB check valve is commonly used in steam and water lines to prevent backflow. The cast steel body provides the necessary rigidity to handle the sudden pressure surges of “closing shock.”

WCB Gate & Globe Valves

Used extensively in oil and gas refineries, these valves provide the “Shut-off” and “Throttling” capabilities needed for non-corrosive hydrocarbons.

6. WCB vs. CF8M: How to Choose?

A frequent question during procurement is: “When should I upgrade from WCB to Stainless Steel (CF8M/SS316)?”

| Feature | WCB (Cast Steel) | CF8M (Stainless Steel) |

| Corrosion Resistance | Low (Requires paint/coating) | High (Excellent against rust/acids) |

| Cost | Economical | High (2-3x WCB price) |

| Typical Media | Oil, Gas, Steam, Water | Chemicals, Seawater, Acids |

Conclusion: Is WCB Right for Your System?

Understanding the meaning of WCB in valves is crucial for system safety. If your media is non-corrosive and stays within moderate temperature ranges, WCB offers the best price-to-performance ratio in the industry.