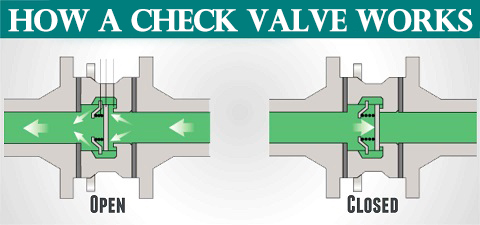

A check valve automatically allows fluid to flow in one direction while blocking reverse flow. Think of it as a one-way door for liquids and gases—it opens when flow moves the right way and slams shut the moment flow tries to reverse. This simple but critical function protects pumps, prevents contamination, and keeps systems running safely.

But what does this mean for your specific application? Whether you’re installing a sump pump, setting up an aquarium, or troubleshooting a water system, understanding exactly what a check valve does—and why it matters—can save you from costly damage and frustrating failures.

Table of Contents

ToggleWhat Does a Check Valve Do? The Simple Explanation

Imagine pouring water through a funnel. Water flows down easily, but if you flip the funnel over, water can’t flow back up through the narrow end. A check valve works on a similar principle—except it uses mechanical components to create a reliable, automatic seal.

Here’s what happens inside a check valve:

| Flow Direction | What the Valve Does | Result |

|---|---|---|

| Forward flow | Internal mechanism opens | Fluid passes through |

| No flow | Mechanism returns to closed position | Valve seals |

| Reverse flow attempted | Pressure pushes mechanism tighter against seat | Backflow blocked |

The beauty of check valves is that they require no electricity, no manual operation, and no monitoring. They respond automatically to flow conditions, making them incredibly reliable.

How Does a Check Valve Work?

The operation of a check valve depends on two forces: flow pressure and a closing mechanism (gravity, spring, or the reverse pressure itself).

Step-by-Step Operation

1. Forward Flow Begins

- Fluid enters the inlet side

- Pressure builds against the valve’s closure mechanism (disc, ball, or flap)

- When pressure exceeds the mechanism’s resistance, it opens

- Fluid flows through to the outlet

2. Flow Stops

- When forward pressure drops, the closure mechanism begins to close

- Springs (if present) or gravity help speed closure

- The valve returns to its sealed position

3. Reverse Flow Attempted

- If pressure builds on the outlet side (trying to push backward)

- This pressure pushes the closure mechanism harder against its seat

- The seal becomes tighter—more backpressure means better sealing

- No fluid passes backward

Why This Matters

This automatic operation means check valves:

- Never need manual adjustment

- Work even during power outages

- Respond instantly to flow changes

- Fail in a predictable way (usually closed)

What Is the Purpose of a Check Valve?

Check valves serve several critical purposes across different systems:

1. Protect Equipment from Damage

Reverse flow can destroy pumps, compressors, and other equipment by:

- Causing reverse rotation (damages motors)

- Creating water hammer (pressure shock)

- Allowing debris to enter sensitive components

A check valve acts as a guardian, ensuring flow only moves in the safe direction.

2. Prevent Contamination

In water systems, backflow can pull contaminated water into clean supply lines. Check valves prevent:

- Garden hose water from siphoning back into your home

- Wastewater from entering potable water systems

- Chemicals from cross-contaminating process lines

3. Maintain System Pressure and Prime

Without check valves, fluid would drain back through pipes when pumps stop, causing:

- Loss of prime (pump must work harder to restart)

- Wasted energy re-pumping the same fluid

- Pressure fluctuations throughout the system

4. Prevent Water Hammer

When pumps stop suddenly, fluid momentum can cause damaging pressure surges. Check valves with controlled closing speeds reduce this shock.

What Does a Check Valve Do on a Sump Pump?

This is one of the most common—and most important—check valve applications. Let’s break it down completely.

The Problem Without a Check Valve

When your sump pump runs, it pushes water up through the discharge pipe and out of your basement. But what happens when the pump turns off?

Without a check valve:

- Pump shuts off

- All the water in the discharge pipe flows back down

- Water returns to the sump pit

- Water level rises, triggering the pump again

- Pump runs, pushes water up, shuts off

- Water drains back down again

- Cycle repeats endlessly

This causes:

- Pump burnout from constant cycling

- Higher electricity bills

- Premature pump failure

- Potential basement flooding when pump dies

What the Check Valve Does

With a check valve installed:

- Pump pushes water up through discharge pipe

- Water passes through the check valve (opens with forward flow)

- Pump shuts off

- Check valve immediately closes

- Water above the valve stays in the pipe—cannot drain back

- Sump pit stays empty until new water enters

- Pump rests until actually needed

Do You Need a Check Valve on a Sump Pump?

Yes, absolutely. Here’s why it’s essential:

| Without Check Valve | With Check Valve |

|---|---|

| Pump cycles constantly | Pump runs only when needed |

| 2-3 year pump lifespan typical | 7-10+ year pump lifespan |

| Higher energy costs | Normal energy consumption |

| Frequent pump replacements | Reliable long-term operation |

| Risk of pump failure during storms | Dependable when you need it most |

Sump Pump Check Valve Installation Tips

- Location: Install 6-12 inches above the pump (accessible for maintenance)

- Orientation: Arrow on valve body must point UP (direction of flow)

- Type: Use a spring-loaded check valve for vertical installations

- Access: Make sure you can reach it for future service

What Does a Check Valve Do in an Aquarium?

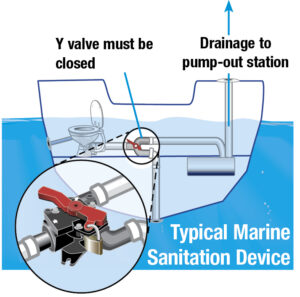

Aquarium check valves serve a different but equally important purpose—they prevent water damage from a phenomenon called back-siphoning.

The Back-Siphon Problem

When you use an air pump for your aquarium:

- Air pump sits below or beside the tank

- Airline tubing runs from pump into the water

- Air bubbles up through an airstone or decoration

But what happens if the power goes out or the pump fails?

Without a check valve, water can siphon backward through the airline tubing, potentially:

- Draining your tank onto the floor

- Destroying your air pump

- Flooding your electrical equipment

- Killing your fish (if tank drains significantly)

What the Check Valve Does

An aquarium air pump check valve installed in the airline tubing:

- Allows air to flow from pump to tank (normal operation)

- Blocks water from flowing back through the tubing

- Protects your pump, floor, and fish

Aquarium Check Valve Installation

Correct installation:

Air Pump → [Airline Tubing] → [CHECK VALVE] → [Airline Tubing] → Tank

Arrow on check valve points TOWARD the tank (direction of airflow)

Placement: Install the check valve:

- Above the water line of your tank

- As close to the tank as practical

- With the flow arrow pointing toward the aquarium

Do You Need a Check Valve for an Air Pump?

Strongly recommended. The small cost of a check valve ($2-5) prevents:

- Water damage to floors and furniture

- Destroyed air pumps ($15-50+)

- Potential fish loss (priceless)

If your air pump is positioned above your tank’s water level, back-siphoning is less likely—but a check valve still provides valuable insurance.

Check Valve for Water Pump Applications

Beyond sump pumps, check valves are essential in many water pump scenarios:

Well Pump Systems

What the check valve does:

- Keeps water in the pipe between pump and pressure tank

- Maintains prime so pump doesn’t have to pull water from deep in the well each cycle

- Prevents water hammer when pump cycles

Installation: Usually at the wellhead or in the pressure tank line

Irrigation and Sprinkler Pumps

What the check valve does:

- Prevents irrigation water from siphoning back into the water supply

- Keeps lines primed for quick startup

- Protects pump from reverse rotation

Booster Pumps

What the check valve does:

- Prevents backflow into the main water supply

- Maintains pressure in the boosted zone

- Protects the pump from reverse flow

Pool and Spa Pumps

What the check valve does:

- Prevents water from draining back when pump stops

- Keeps pump primed for efficient operation

- Reduces strain on pump startup

Types of Check Valves for Different Applications

Different situations call for different check valve types:

| Application | Best Check Valve Type | Why |

|---|---|---|

| Sump pump | Spring-loaded (silent or standard) | Works vertically, fast closure |

| Aquarium air line | Inline plastic check valve | Lightweight, inexpensive, fits airline tubing |

| Water heater | Brass swing check | Durable, handles hot water |

| Pool/spa | PVC swing or spring check | Chemical resistant, sized for large flow |

| Well system | Foot valve (check valve + strainer) | Keeps prime, filters debris |

| General plumbing | Brass or PVC swing check | Reliable, easy to service |

Common Check Valve Problems

Even simple devices can fail. Here’s what to watch for:

| Problem | Symptoms | Likely Cause | Solution |

|---|---|---|---|

| Won’t open | No flow through system | Debris blocking mechanism, installed backward | Clean valve, verify orientation |

| Won’t close | Backflow occurring, pump cycling | Debris on seat, worn seal, damaged disc | Clean or replace valve |

| Noisy operation | Banging, clunking sounds | Valve too large, water hammer | Resize valve, add water hammer arrestor |

| Leaking | Drips at connections | Loose fittings, damaged threads | Tighten or replace fittings |

When to Replace a Check Valve

Replace your check valve if:

- Backflow is occurring (pump cycling unnecessarily)

- Visible damage or corrosion

- Valve is stuck open or closed

- Seals are visibly worn

- It’s been 5-10+ years (preventive maintenance)

Quick Reference: Check Valve Applications

| Application | Do You Need a Check Valve? | What It Prevents |

|---|---|---|

| Sump pump | Yes, essential | Pump cycling, burnout, basement flooding |

| Aquarium air pump | Strongly recommended | Back-siphoning, water damage, pump damage |

| Well pump | Yes, essential | Loss of prime, pump strain |

| Water heater | Required by code in many areas | Thermal expansion backflow |

| Irrigation system | Yes, often required by code | Contamination of water supply |

| Pool pump | Recommended | Loss of prime, pump strain |

Conclusion

A check valve does one simple job—it lets fluid flow one way and blocks it from flowing backward. But this simple function is critical for protecting pumps, preventing water damage, avoiding contamination, and keeping systems running efficiently.

Key takeaways:

- Check valves open with forward flow and close automatically when flow stops or reverses

- Sump pumps absolutely need check valves to prevent constant cycling and premature failure

- Aquarium air pumps should have check valves to prevent back-siphoning and water damage

- The right check valve type depends on your specific application (spring-loaded for vertical, swing for horizontal)

- Check valves require no power or manual operation—they work automatically

Whether you’re protecting a basement sump pump or a small aquarium air pump, a properly installed check valve provides reliable, maintenance-free protection for years.

Need help choosing the right check valve for your application? Contact our team for expert recommendations on valve selection and sizing.