The question, “What is a Block Valve?” targets the most fundamental component in fluid handling and pipeline safety. A block valve is, quite simply, any valve installed in a pipeline whose primary function is to stop the flow of fluid completely, thereby isolating one section of the system from another. It acts as a primary boundary, ensuring that when maintenance is required on a downstream component—like a pump, filter, or heat exchanger—the fluid supply can be reliably shut off without disrupting the rest of the operational network. In essence, the block valve is the bedrock of safety and maintainability in every industrial and commercial fluid system.

Unlike throttling valves, which are designed to modulate flow rate, a true block valve is engineered for on/off service and a tight, absolute seal to achieve positive isolation.

Table of Contents

Toggle🛡️ The Crucial Role of the Block Valve

The functionality of the block valve extends far beyond mere shut-off; it is essential for operational integrity and personnel safety.

1. Isolation for Maintenance and Repair

The primary function. By closing the block valve, engineers can create a safe, fluid-free zone to perform repairs, inspections, or equipment replacement. Without reliable isolation, simple maintenance tasks would necessitate costly and time-consuming system-wide shutdowns.

2. Safety Barrier

In emergency scenarios (such as a pipeline rupture, fire, or uncontrolled leak), immediate closure of the nearest block valve is the critical first step to contain the fluid and limit environmental damage or hazard exposure to personnel.

3. System Zoning

Block valves are used to divide vast, complex pipeline networks into smaller, manageable zones or segments. This allows operators to test new sections, bypass operational equipment, or isolate a failed segment while keeping the rest of the process running.

🛠️ Common Valve Types that Function as a Block Valve

Because the term block valve describes a function (isolation), several different valve designs are used to fulfill this role. Selection depends on the fluid handled, the pressure, and the desired ease of operation.

1. Gate Valves

Mechanism: Uses a flat wedge (gate) that moves perpendicular to the flow path.

Block Quality: Provides a tight seal and, when fully open, offers a straight-through, unobstructed flow path, resulting in minimal pressure drop.

Best Used For: Large diameter lines and services requiring full, unrestricted flow when open. They are typically used where infrequent operation is acceptable.

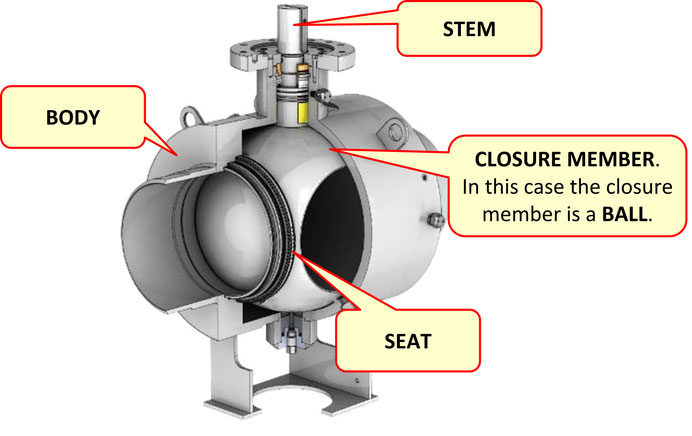

2. Ball Valves

Mechanism: Uses a spherical ball with a bore rotated 90° (quarter-turn) to open or close the flow.

Block Quality: Offers quick, bubble-tight shut-off and high reliability. Like the Gate Valve, full-bore designs minimize pressure drop.

Best Used For: General utility lines, residential plumbing, and any industrial service requiring fast, reliable on/off isolation. The most popular modern block valve.

3. Plug Valves

Mechanism: Uses a tapered or cylindrical plug with a bore that is rotated 90°.

Block Quality: Excellent for quick shut-off and handles high temperatures and abrasive slurries better than some other designs due to its robust sealing surface.

Best Used For: Services handling slurries, high-viscosity fluids, or where fast quarter-turn operation is required in dirty services.

⚠️ Beyond Simple Isolation: Block Valve Configurations

While a single block valve can provide basic isolation, high-risk or critical services often require enhanced security, leading to specialized configurations:

Double Block and Bleed (DBB): As mentioned previously, this configuration uses two block valves separated by a smaller bleed valve. It provides verifiable double isolation, ensuring that pressure is completely eliminated between the two closed valves—a non-negotiable safety standard for handling hazardous fluids.

Block and Bypass: Used in large pipelines where line pressure is high. A small bypass line with a block valve is installed parallel to the main, larger block valve. The bypass valve is opened first to equalize the pressure across the main valve before attempting to open the large block valve, thus reducing the torque required and preventing damage.

📈 Expert Perspective: Reliability is Key

An engineer’s primary requirement for a block valve is its sealing integrity. Unlike a control valve, which is expected to leak slightly during throttling, a block valve must provide a positive, absolute seal, often referred to as “Class VI shut-off” in industry standards.

The material selection—be it forged steel for high-pressure oil lines or stainless steel for corrosive chemical service—must match the operating conditions precisely. Ultimately, the quality and reliability of the block valve determine the safety and longevity of the entire process line it protects.