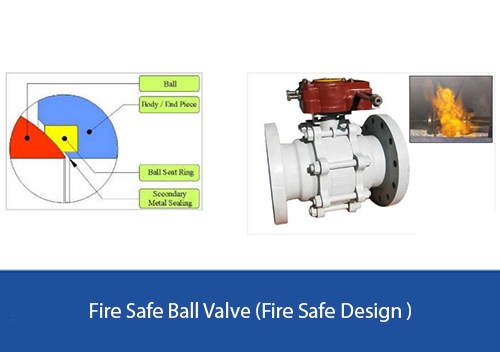

In a refinery or chemical plant, a fire is the ultimate nightmare. In such an event, valves must act as critical safety barriers. But here is the problem: most standard ball valves use soft seats (PTFE/Teflon), which melt at temperatures above 200°C.

When the soft seats melt, a standard valve will fail, allowing flammable fluids to feed the fire. A Fire-Safe Design Ball Valve is engineered to remain functional and prevent leakage even after its primary seals have been completely incinerated.

Table of Contents

Toggle1. The Core Technology: Secondary Metal Sealing

A fire-safe ball valve is essentially a “hybrid” system. It provides the best of both worlds: bubble-tight sealing during normal operation and survival-mode sealing during a fire.

Primary Seal (The Soft Seat): Under normal conditions, the ball rests against a soft seat (PTFE/PEEK), ensuring Class VI zero-leakage.

Secondary Seal (The Metal Lip): The valve body features a machined metal seat lip behind the soft seat.

The “Fire” Event: When a fire occurs and the soft seat melts away, the line pressure pushes the ball forward until it makes contact with the secondary metal seat. This metal-to-metal contact provides a backup seal to stop the flow from fueling the fire.

2. Key Industry Standards: API 607 vs. API 6FA

To be legally labeled as “Fire-Safe,” a valve must pass rigorous third-party testing. You will see these two standards most often:

API 607: The most common standard. It tests valves in a partially open position, then subjects them to fire (750°C to 1000°C) for 30 minutes, and finally tests their sealing ability after they have cooled down (quenched).

API 6FA: Similar to 607, but typically used for high-pressure, large-diameter valves (API 6D valves) used in pipelines.

ISO 10497: The international equivalent to API 607.

3. Beyond the Seats: Stem and Body Sealing

A true fire-safe design doesn’t stop at the seats. There are two other “leak paths” that must be protected:

A. Fire-Safe Stem Packing

Standard O-rings will evaporate in a fire. Fire-safe valves use Graphite Packing. Graphite is incredibly heat-resistant and maintains a seal around the stem even when the secondary seals are under extreme thermal stress.

B. Body Gaskets

The joints where the valve body pieces connect must also be fire-proof. Instead of simple rubber or plastic gaskets, fire-safe valves use Spiral Wound Gaskets made of stainless steel and graphite.

4. Comparing Standard vs. Fire-Safe Ball Valves

| Feature | Standard Ball Valve | Fire-Safe Ball Valve |

| Primary Seal | Soft Seat (PTFE) | Soft Seat (PTFE/PEEK) |

| Backup Seal | None | Machined Metal Lip |

| Stem Packing | PTFE / O-Ring | Flexible Graphite |

| Body Gaskets | PTFE / Rubber | Spiral Wound (SS+Graphite) |

| Certification | N/A | API 607 / API 6FA |

| Application | Water, Air, General Chem | Refineries, Oil & Gas, LPG/LNG |

5. Why “Fire-Safe” is a Must for Your Facility

Legal Compliance: In many jurisdictions, OSHA and insurance companies require fire-safe certified valves for any pipeline carrying flammable media.

Explosion Prevention: By preventing internal and external leakage during a fire, these valves prevent “flash-over” events that lead to catastrophic explosions.

Emergency Operation: A fire-safe valve is designed so that it can still be operated (closed) even after being exposed to high heat, allowing operators to isolate the fire source.

Conclusion: Don’t Risk It with Standard Valves

If your media is flammable, a standard ball valve is a liability. A Fire-Safe Design Ball Valve is a small investment that provides the ultimate insurance policy for your personnel and your plant. When the heat is on, the “Secondary Metal Seal” is the only thing standing between a controlled incident and a total disaster.