A gate valve is a linear motion valve used to start or stop fluid flow by raising or lowering a flat gate (wedge) into the flow path. When fully open, the gate retracts completely out of the flow, creating an unobstructed straight-through passage with minimal pressure drop. When closed, the gate blocks flow entirely.

Gate valves are designed for fully open or fully closed operation—not for regulating or throttling flow. They’re found in homes, water treatment plants, oil refineries, and virtually every industry where fluid isolation is needed. In this guide, we’ll explain how gate valves work, explore the different types, and compare them to globe valves and other common valve types.

Table of Contents

ToggleWhat Is a Gate Valve Used For?

The primary gate valve function is isolation—completely stopping or allowing flow. Here’s what gate valves are used for:

| Application | Why Gate Valves Work Well |

|---|---|

| Main water shutoffs | Full bore design, minimal pressure loss |

| Fire protection systems | Reliable isolation when needed |

| Oil and gas pipelines | Handles high pressure, full shutoff |

| Industrial process lines | Clean isolation, easy to automate |

| Steam systems | Withstands high temperature and pressure |

| Wastewater treatment | Works with solids-laden fluids |

Gate Valve Purpose: On/Off Control

The purpose of a gate valve is simple: provide a reliable way to completely isolate a section of piping. Unlike valves designed for flow control, gate valves are meant to be either:

- Fully open: Gate completely retracted, unrestricted flow

- Fully closed: Gate fully lowered, zero flow

Important: Gate valves should NOT be used for throttling (partially open operation). Doing so causes:

- Vibration and noise

- Rapid wear on the gate and seats

- Erosion damage from high-velocity flow

- Premature valve failure

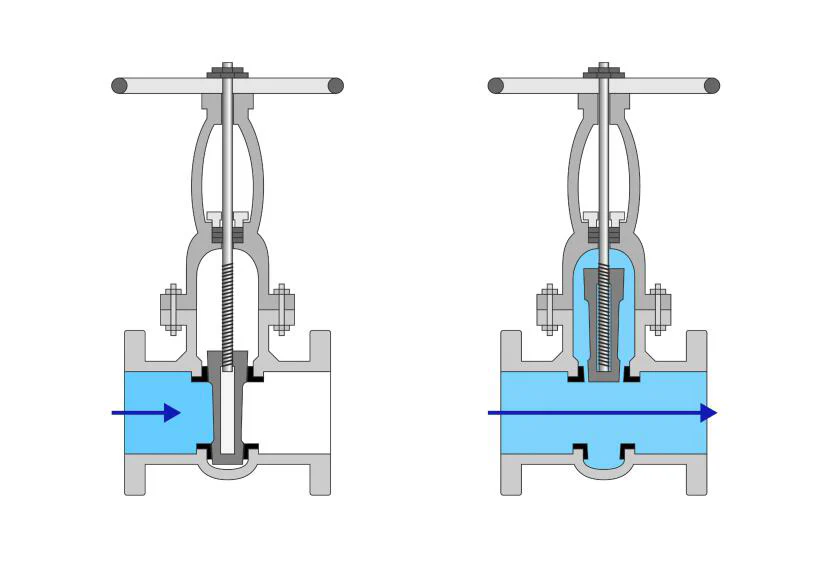

How Does a Gate Valve Work?

Understanding gate valve operation helps you use and maintain these valves properly.

Gate Valve Working Principle

Step-by-Step Operation

Opening the valve:

- Turn the handwheel counterclockwise

- Stem rises (or rotates, depending on design)

- Gate lifts out of the flow path

- When fully open, gate sits in the bonnet area above the flow

- Fluid passes through unobstructed

Closing the valve:

- Turn the handwheel clockwise

- Stem lowers the gate into the flow path

- Gate wedges between the seat surfaces

- Metal-to-metal (or resilient) seal stops flow completely

Gate Valve Parts and Function

| Part | Function |

|---|---|

| Handwheel | Manual operation—turn to open/close |

| Stem | Connects handwheel to gate, transfers motion |

| Packing | Seals around stem to prevent leakage |

| Bonnet | Top housing that contains stem and packing |

| Gate (wedge/disc) | Movable element that blocks or allows flow |

| Body | Main housing with inlet/outlet connections |

| Seats | Sealing surfaces where gate contacts body |

Types of Gate Valves

Different applications require different types of gate valves. The main variations are based on gate design, stem movement, and body construction.

By Gate (Wedge) Design

Solid Wedge Gate Valve

- Design: Single solid wedge-shaped gate

- Advantages: Simple, durable, works in any position

- Best for: General service, non-critical applications

- Considerations: Can stick in high-temperature service due to thermal expansion

Flexible Wedge Gate Valve

- Design: Solid wedge with perimeter cut allowing slight flex

- Advantages: Compensates for seat misalignment and thermal changes

- Best for: Steam service, temperature cycling applications

- Considerations: Slightly more complex than solid wedge

Split Wedge (Parallel Disc) Gate Valve

- Design: Two-piece disc that spreads against seats

- Advantages: Self-adjusting seal, reduces binding

- Best for: High-temperature service, thermal cycling

- Considerations: More complex, higher cost

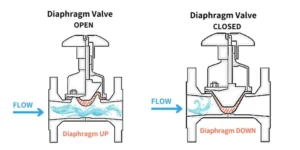

Resilient Wedge Gate Valve

- Design: Gate with rubber/elastomer coating

- Advantages: Bubble-tight seal, handles debris well

- Best for: Water service, wastewater, slurries

- Considerations: Temperature limited by elastomer

Gate Valve Wedge Types Comparison

| Wedge Type | Sealing | Temperature Range | Best Application |

|---|---|---|---|

| Solid wedge | Good | Wide range | General purpose |

| Flexible wedge | Very good | High temp | Steam, thermal cycling |

| Split wedge | Excellent | High temp | Critical isolation |

| Resilient wedge | Bubble-tight | Limited by rubber | Water, wastewater |

By Stem Design

Rising Stem Gate Valve

- How it works: Stem rises as valve opens—visible position indicator

- Advantages: Easy to see if valve is open or closed

- Considerations: Requires vertical clearance above valve

- Common in: Industrial applications, above-ground installations

Non-Rising Stem Gate Valve

- How it works: Stem threads into gate; stem rotates but doesn’t rise

- Advantages: Compact, works in limited spaces

- Considerations: No visual position indication

- Common in: Underground service, confined spaces

By Bonnet Design

| Bonnet Type | Description | Best For |

|---|---|---|

| Bolted bonnet | Bonnet bolted to body | Standard service, easy maintenance |

| Welded bonnet | Permanently welded | High pressure, no leakage paths |

| Pressure seal bonnet | Internal pressure tightens seal | Very high pressure applications |

| Union bonnet | Threaded union connection | Small valves, frequent maintenance |

Gate Valve in Plumbing

What is a gate valve in plumbing? In residential and commercial plumbing, gate valves serve as main shutoff valves for water supply systems.

Common Plumbing Applications

- Main water shutoff: Where water enters the building

- Branch line isolation: Shutting off water to specific areas

- Water heater isolation: For maintenance and replacement

- Outdoor faucet shutoffs: Winterizing protection

Gate Valve Plumbing Considerations

| Factor | Recommendation |

|---|---|

| Material | Brass for potable water, bronze for corrosion resistance |

| Size | Match existing pipe size (typically 1/2″ to 1″) |

| Connection | Threaded (NPT), solder, or compression |

| Operation | Full open or full closed only |

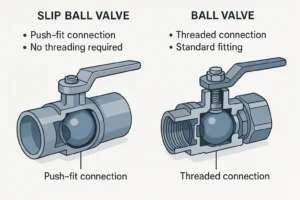

Why Ball Valves Are Replacing Gate Valves in Plumbing

While gate valves have been standard in plumbing for decades, ball valves are increasingly preferred because they:

- Open/close with a quarter turn (faster)

- Are more compact

- Less prone to corrosion and sticking

- Provide more reliable sealing

However, gate valves remain common in older homes and are still specified for certain applications.

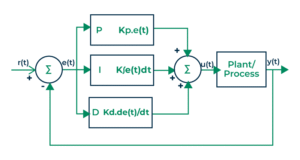

Gate Valve vs Globe Valve

One of the most common questions is the difference between gate valves and globe valves. Let’s compare them in detail.

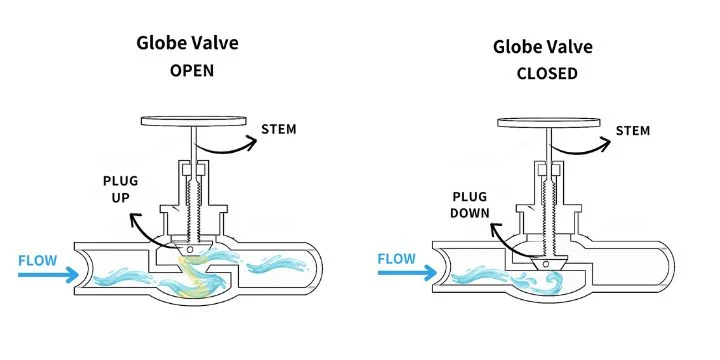

What Is a Globe Valve?

A globe valve is a linear motion valve with a plug-type disc that moves perpendicular to the flow path. Unlike gate valves, globe valves are designed for throttling and flow regulation—not just on/off service.

How Does a Globe Valve Work?

Gate Valve vs Globe Valve Comparison

| Feature | Gate Valve | Globe Valve |

|---|---|---|

| Primary function | On/off isolation | Throttling and flow control |

| Flow path | Straight through | Tortuous (changes direction) |

| Pressure drop | Very low when open | Higher due to flow path |

| Throttling ability | Poor (causes damage) | Excellent (designed for it) |

| Sealing | Good (metal or resilient) | Very good (plug and seat) |

| Operation speed | Slow (many turns) | Slow (many turns) |

| Cost | Lower | Higher |

| Maintenance | Simple | More complex |

When to Use Each

Use a gate valve when:

- You need full isolation (on/off only)

- Minimal pressure drop is important

- Flow will be either fully on or fully off

- Cost is a consideration

Use a globe valve when:

- You need to regulate flow rate

- Throttling is required

- Frequent adjustment is needed

- Precise flow control matters

Globe Valve Purpose and Applications

What is a globe valve used for?

- Steam flow control

- Cooling water regulation

- Fuel oil systems

- Process control applications

- Any application requiring flow modulation

Gate Valve vs Ball Valve

Another common comparison is between gate valves and ball valves.

| Feature | Gate Valve | Ball Valve |

|---|---|---|

| Operation | Multi-turn (slow) | Quarter-turn (fast) |

| Position indicator | Rising stem visible | Handle position |

| Size range | Small to very large | Small to medium typical |

| Pressure drop | Very low | Very low |

| Throttling | Not recommended | Not recommended |

| Sealing | Good | Excellent |

| Cost (large sizes) | Lower | Higher |

| Maintenance | More complex | Simple |

Bottom line: For most residential and light commercial applications, ball valves are replacing gate valves due to faster operation and better reliability. Gate valves remain preferred for large industrial applications.

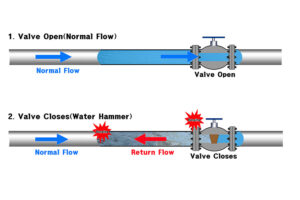

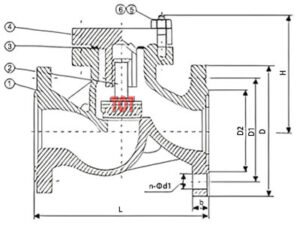

Gate Valve vs Check Valve

People sometimes confuse these two valve types, but they serve completely different purposes.

What Is a Check Valve?

A check valve is an automatic valve that allows flow in one direction only. Unlike gate valves, check valves:

- Have no manual operator

- Work automatically based on flow direction

- Cannot be used to isolate flow on demand

Key Differences

| Feature | Gate Valve | Check Valve |

|---|---|---|

| Operation | Manual (handwheel) | Automatic (flow-activated) |

| Purpose | Isolate flow on command | Prevent backflow |

| Control | Open, close, or isolate | One-way flow only |

| User input | Required | None needed |

Check Valve Purpose

The purpose of a check valve is to prevent reverse flow—protecting pumps, preventing contamination, and maintaining system pressure. They’re often used together with gate valves in pump systems.

Gate Valve Selection Guide

Step 1: Determine Application Requirements

| Question | Considerations |

|---|---|

| What fluid? | Water, steam, oil, gas, chemicals |

| What pressure? | Determines pressure class (150#, 300#, etc.) |

| What temperature? | Affects material selection |

| What size? | Match pipe diameter |

Step 2: Choose Gate Type

| If You Need… | Choose |

|---|---|

| General service, simple | Solid wedge |

| High temperature, steam | Flexible wedge |

| Critical isolation | Split wedge |

| Water/wastewater service | Resilient wedge |

Step 3: Select Stem Design

| If You Have… | Choose |

|---|---|

| Space above valve, need position indication | Rising stem |

| Limited vertical space, underground | Non-rising stem |

Step 4: Specify Materials

| Service | Body Material | Trim Material |

|---|---|---|

| Potable water | Brass, bronze | Brass |

| Industrial water | Cast iron, ductile iron | Bronze, stainless |

| Steam | Carbon steel, cast steel | Stainless steel |

| Corrosive fluids | Stainless steel, alloy | Matched alloys |

Gate Valve Installation Best Practices

- Install in correct orientation: Most gate valves can be installed in any position, but check manufacturer guidelines

- Ensure full open/close operation: Never leave partially open

- Support piping: Don’t let valve support pipe weight

- Allow stem clearance: Rising stem valves need space above

- Install accessible: Position for easy handwheel access

- Use proper gaskets: Match gasket material to service conditions

- Open slowly: Prevent water hammer by opening gradually

Common Gate Valve Problems

| Problem | Cause | Solution |

|---|---|---|

| Won’t close completely | Debris on seat, worn seats | Clean valve, lap or replace seats |

| Stem leaking | Worn packing | Tighten or replace packing |

| Hard to operate | Corrosion, lack of use | Exercise regularly, lubricate stem |

| Gate stuck | Thermal binding, corrosion | May need disassembly and cleaning |

| Vibration/noise | Throttling (partial open) | Open fully or close fully |

Conclusion

A gate valve is a fundamental isolation valve designed to fully stop or fully allow fluid flow. Its straight-through design provides minimal pressure drop when open, making it ideal for applications where unrestricted flow and reliable shutoff are needed—but not for throttling or flow regulation.

Key takeaways:

- Gate valves are for on/off service only—never throttle with a gate valve

- Choose wedge type based on application (solid, flexible, split, or resilient)

- Rising stem valves provide visual position indication; non-rising stems save space

- Globe valves are better for flow control; gate valves are better for isolation

- Ball valves are replacing gate valves in many plumbing applications due to faster operation

- Gate valves and check valves serve different purposes—manual isolation vs automatic backflow prevention

Understanding gate valve types and proper application ensures reliable, long-lasting performance in your piping systems.

Need help selecting the right gate valve? Contact our engineering team for expert guidance on valve specification and sizing.