In industries that handle slurry, viscous fluids, or bulk solids, standard valves often struggle with clogging and sealing issues. This is where the knife gate valve comes in. Designed with a sharp-edged gate that can cut through thick media, it has become a go-to solution for mining, wastewater treatment, pulp and paper, and chemical processing industries.

This article explains what a knife gate valve is, how it works, its advantages, applications, and key considerations when selecting one.

Table of Contents

Toggle⚙️ Definition: What Is a Knife Gate Valve?

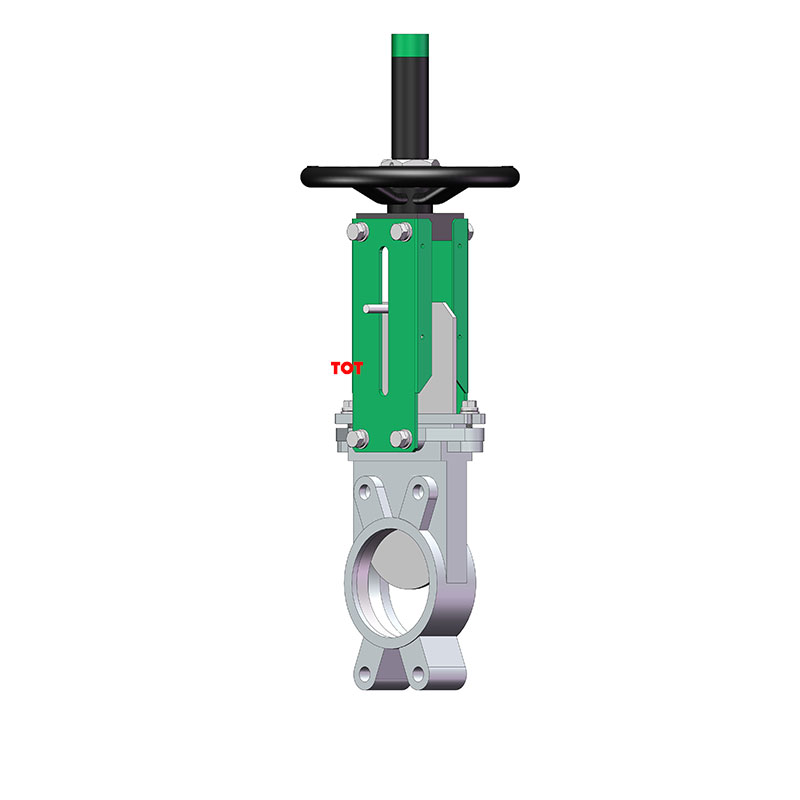

A knife gate valve is a type of industrial valve used to control the flow of media in a pipeline. Unlike a standard gate valve that uses a wedge-shaped gate, a knife gate valve has a flat, sharp-edged blade designed to cut through dense or abrasive fluids, such as slurry, mud, or pulp.

It is particularly effective in on/off applications where a full flow or complete shutoff is required.

🔧 How Does a Knife Gate Valve Work?

The working principle is straightforward:

Open Position – The gate is lifted out of the flow path, allowing the medium to pass through with minimal pressure drop.

Closing – The sharp-edged gate lowers and cuts through solids or fibers suspended in the fluid.

Shutoff – The gate presses against a seat (metal or resilient material), providing a tight seal to stop flow.

👉 Knife gate valves can be operated manually (handwheel) or with electric, pneumatic, or hydraulic actuators depending on system requirements.

✅ Advantages of Knife Gate Valves

Handles Slurry & Thick Media – Designed to cut through solids without clogging.

Low-Pressure Drop – Full bore design allows unimpeded flow when open.

Cost-Effective – Generally more affordable than other heavy-duty valves of similar size.

Compact & Lightweight – Easier to install in large-diameter pipelines.

Versatile Operation – Available in manual, pneumatic, and motorized versions.

🏭 Common Applications

Knife gate valves are widely used in industries where fluids contain solids, abrasives, or high viscosity materials, such as:

Mining & Mineral Processing – Tailings, slurry, and abrasive materials.

Pulp & Paper Mills – Pulp stock, wood chips, recycled fiber.

Wastewater Treatment – Sludge, grit, and sediment-heavy liquids.

Power Plants – Fly ash and bottom ash handling.

Food & Beverage – Thick syrups, grain mash, or semi-solid products.

Chemical & Petrochemical – Corrosive slurries and chemical byproducts.

🔍 Knife Gate Valve vs. Standard Gate Valve

| Feature | Knife Gate Valve | Standard Gate Valve |

|---|---|---|

| Design | Flat blade with sharp edge | Wedge-shaped gate |

| Media | Slurry, viscous, abrasive | Clean liquids, gases |

| Sealing | Good for on/off, less for throttling | Better for tight shutoff |

| Cost | Lower, especially in large sizes | Higher in larger sizes |

| Applications | Mining, pulp, wastewater | Oil, gas, clean water |

👉 In short: Knife gate valves excel in dirty, abrasive, and slurry conditions, while gate valves are better for clean media.

⚠️ Limitations to Consider

While highly useful, knife gate valves are not suitable for every application:

Not ideal for high-pressure systems – Most are designed for low to medium pressure.

Limited throttling capability – Best for on/off use rather than precise flow control.

Potential leakage – Resilient-seated models may leak if solids prevent a perfect seal.

📩 Conclusion

A knife gate valve is a specialized industrial valve designed to handle slurries, thick fluids, and abrasive materials where other valves fail. With its ability to cut through media and provide reliable shutoff, it is an essential component in mining, wastewater, pulp & paper, and chemical processing industries.

When selecting a knife gate valve, always consider the media type, pressure, temperature, and actuation method to ensure optimal performance.