Table of Contents

ToggleQuick Answer

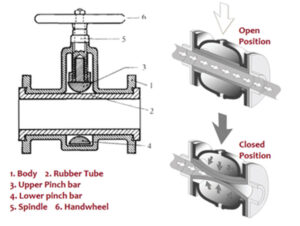

A pinch valve is a type of control valve that uses a pinching effect to control or shut off fluid flow. It consists of a flexible rubber sleeve inside a housing—when pressurized air is applied, the sleeve gets pinched closed to stop flow. When pressure is released, the sleeve opens. The key advantage: only the rubber sleeve contacts the media, making pinch valves ideal for abrasive, corrosive, or contamination-sensitive materials.

Simple analogy: Like pinching a garden hose with your fingers to stop water flow—but automated and precise.

Understanding Pinch Valves

What Makes Them Unique

A pinch valve is a full bore or fully ported type of control valve which uses a pinching effect to obstruct fluid flow.

Three simple parts:

- Housing/Body – Outer metal or plastic casing

- Flexible Sleeve – Rubber or elastomer tube (the only wetted part)

- Pinching Mechanism – Air-operated, mechanical, or manual

The key difference: In most valves, the flowing media contacts metal parts. In a pinch valve, the media only touches the rubber sleeve. The body and mechanism stay isolated from the process fluid.

How a Pinch Valve Works

Open position:

┌────────────────────────┐

│ Housing │

│ ╔════════════════╗ │

│ ║ ║ │

│ ║ [Rubber Sleeve] ║ │ ← Fluid flows freely

│ ║ ║ │

│ ╚════════════════╝ │

└────────────────────────┘

Full bore, no restriction

Closed position:

┌────────────────────────┐

│ Housing │

│ ╔════════════════╗ │

│ ║ >< ║ │ ← Sleeve pinched shut

│ ║ [Pinched] ║ │

│ ║ >< ║ │

│ ╚════════════════╝ │

└────────────────────────┘

Flow completely stopped

Operating principle:

Air-operated pinch valves:

- To close: Pressurized air enters the valve body

- Air pushes down on the rubber sleeve from outside

- Sleeve collapses inward, pinching shut

- Flow stops completely

- To open: Air pressure released

- Sleeve’s elastic property rebounds to original shape

- Upstream flow pressure helps fully open

- Full flow restored

Mechanical pinch valves:

- Handwheel or pneumatic actuator controls pinch bars

- Bars squeeze sleeve together to close

- Spring return or manual action to open

- No air supply needed

Why the Sleeve Material Matters

The flexible internal rubber sleeve in the valve keeps the media isolated from the rest of the valve, preventing contamination or damage to the valve’s other components.

Common sleeve materials:

- Natural rubber (general purpose)

- NBR/Nitrile (oil resistance)

- EPDM (chemical resistance)

- Silicone (high temperature)

- FDA-approved food-grade rubber

- PTFE-lined (extreme chemical resistance)

Selection criteria:

- Chemical compatibility with media

- Temperature range

- Abrasion resistance

- Pressure rating

- Food/pharmaceutical compliance

Types of Pinch Valves

1. Air-Operated Pinch Valves

How they work: Air-operated pinch valves consist of an elasticised reinforced rubber hose, a type of housing, and two socket end covers (or flanges).

Operation:

- Compressed air (typically 80-120 PSI) supplied to valve body

- Air pressure pinches sleeve closed

- When air exhausts, elastic rubber hose opens due to process flow force

- Normally open design (closed when air applied)

Advantages:

- ✅ Fast actuation (1-2 seconds)

- ✅ No manual operation needed

- ✅ Can be automated with solenoids

- ✅ Remote control possible

- ✅ Consistent operation

Disadvantages:

- ❌ Requires compressed air supply

- ❌ Air consumption ongoing when closed

- ❌ Cannot operate without air

Best for:

- Automated processes

- Remote locations with air supply

- High-frequency cycling

- Integration with control systems

2. Mechanical Pinch Valves

How they work: The manual version simply works by turning a hand wheel to open/close the valve.

Two control options:

Manual (handwheel):

- Turn wheel to compress pinch bars

- Bars squeeze sleeve closed

- Turn opposite direction to open

- Physical effort required

Pneumatic actuation: A pneumatically operated mechanical pinch valve works by compressor bars pulling the sleeve open or pushing together to keep the sleeve closed.

Advantages:

- ✅ No air supply needed (manual)

- ✅ Simple, reliable design

- ✅ Lower initial cost

- ✅ Easy maintenance

Disadvantages:

- ❌ Slower operation

- ❌ Requires manual access

- ❌ Not suitable for frequent cycling

Best for:

- Infrequent operation

- No compressed air available

- Simple on/off applications

- Budget-conscious installations

3. Open Body Design

Construction:

- No metal casing around sleeve

- Skeletal metal frame only

- Sleeve exposed

- Compact design

Features:

- Lightweight

- Easy sleeve inspection

- Simple replacement

- Lower cost

Limitations:

- Less protection for sleeve

- Not suitable for harsh environments

- Limited pressure ratings

- Vacuum applications problematic

4. Enclosed Body Design

Construction:

- Metal casing fully encloses sleeve

- Provides secondary containment

- Drain connections available

- More robust

Features:

- Better protection

- Can detect sleeve leaks

- Higher pressure capability

- Suitable for hazardous media

Applications:

- Corrosive chemicals

- High-pressure systems

- Safety-critical applications

- Outdoor installations

5. Pressure-Assisted Design

The pressure-assisted pinch valve uses outside fluid pressure to close the valve.

How it works:

- External fluid introduced to valve body (outside sleeve)

- When external pressure exceeds internal media pressure

- Sleeve collapses and closes

- Very simple design

Advantages:

- ✅ No actuator needed

- ✅ Very low cost

- ✅ Simple operation

Disadvantages:

- ❌ On/off only (no throttling)

- ❌ Requires pressure source

- ❌ Limited control

Best for:

- Simple shutoff applications

- Cost-sensitive projects

Normally Open vs Normally Closed

Pinch Valves are described by 3 types, Normally Open (NO), Normally Closed (NC), and Changeover (CO).

Normally Open (NO):

- Valve open when no power/air applied

- Air/power closes the valve

- Fail-safe open design

- Common in safety applications

Normally Closed (NC):

- Spring holds valve closed when no power

- Air/power opens the valve

- Fail-safe closed design

- Used where safety requires shutoff

Changeover (CO):

- Two channels, one open and one closed

- Switching between two flow paths

- Diverter valve function

Key Advantages of Pinch Valves

1. Full Bore Flow

When in the open position, the Pinch Valve has a full and true bore.

Benefits:

- No flow restriction

- Minimal pressure drop

- Handles solids easily

- Large particles pass through

- Self-cleaning action

Why it matters: Conventional valves have internal parts that restrict flow and trap solids. Pinch valves offer unobstructed passage.

2. Zero Contamination

The fluid being carried does not come in contact with the metal surface.

How it works:

- Only rubber sleeve contacts media

- All metal parts isolated

- No lubrication in flow path

- Clean, sterile operation

Applications:

- Food processing

- Pharmaceutical manufacturing

- Sterile applications

- Preventing metal contamination

3. Excellent Abrasion Resistance

When abrasive media strikes the rubber pinch valve sleeve, the sleeve absorbs the impact and deflects its energy back to the media.

Why rubber works:

- Resilient, elastic material

- Absorbs particle impact

- Deflects energy rather than eroding

- Much longer life than metal seats

Suitable for:

- Slurries with sand, gravel, cement

- Mining applications

- Pulp and paper

- Wastewater treatment

4. Self-Cleaning Action

As the sleeve pinches closed, scaling begins to flake due to stretching. The accelerated flow velocity blasts the scale off the elastic surface.

How it happens:

- Sleeve begins to close

- Material/scale buildup starts to flake

- Flow velocity increases as opening narrows

- Higher velocity blasts flaked material away

- Valve stays clean, no buildup

Result:

- Won’t jam or stick

- No seat damage from particles

- Reliable operation even with dirty media

5. Low Maintenance

The Pinch Valve does not have any additional parts that will need replacing every so often such as rings, seals and packing etc.

What this means:

- No valve stem seals

- No packing glands

- No seat rings to replace

- Only sleeve wears (predictable)

Cost benefit:

- Lower lifecycle cost

- Less downtime

- Simple replacement

- “Fit and forget” operation

6. Bidirectional Operation

Pinch valves offer a reliable bidirectional shut-off with zero leakage.

Advantages:

- Flow from either direction

- Same sealing effectiveness

- No directional installation requirement

- Versatile in piping design

7. Handles Difficult Media

Successfully used with:

- Abrasive slurries (mining, dredging)

- Corrosive chemicals (acids, alkalis)

- Viscous materials (adhesives, sludge)

- Fibrous media (pulp, textiles)

- Granular solids (cement, sand, pellets)

- Food products (sauces, purees)

- Pharmaceutical ingredients

Applications and Industries

Industrial Applications

Mining and Minerals:

- Slurry transport

- Tailings handling

- Ore processing

- Mineral slurries

- Coal washing

Chemical Processing:

- Acids and alkalis

- Corrosive chemicals

- Catalyst slurries

- Abrasive chemicals

- Hazardous materials

Wastewater Treatment:

- Sludge handling

- Grit chambers

- Thickener underflow

- Filter backwash

- Digester feed

Cement and Concrete:

- Cement slurry

- Fly ash handling

- Aggregate transport

- Ready-mix discharge

Pulp and Paper:

- Stock handling

- Bleach plant

- Black liquor

- White water systems

- Fiber suspensions

Food and Beverage

Why pinch valves excel:

- No metal contact with product

- Easy to clean (CIP compatible)

- No crevices for bacteria

- FDA-approved materials available

- Sterile operation

Applications:

- Dairy products

- Fruit juices and purees

- Sauces and condiments

- Brewing and wine

- Food slurries

Pharmaceutical and Medical

Critical features:

- Sterile operation

- No contamination

- Easy validation

- Cleanable design

- GMP compliant

Applications:

- API (active ingredient) handling

- Sterile processing

- Biopharmaceuticals

- Tablet coatings

- Medical device manufacturing

Other Applications

Agriculture:

- Irrigation systems

- Fertilizer slurries

- Animal feed

- Pesticide handling

Textile:

- Fiber suspensions

- Dye solutions

- Chemical additives

Plastics:

- Resin slurries

- Pigment suspensions

- Plastic pellets

Power Generation:

- Fly ash handling

- Scrubber slurries

- Limestone slurries

- Coal ash

Selection Criteria

Pressure Considerations

To prevent a failure to open/close, take the following pressure differentials into account:

Opening:

- Operating pressure must exceed control pressure

- Typical control pressure = 0 bar when opening

- Need sufficient differential for sleeve to open

Closing:

- Control pressure must exceed operating pressure

- Without adequate differential, valve won’t close

- Pressure difference pushes sleeve shut

Vacuum applications: The valve is unsuitable for vacuum applications as suction inside the valve may lead the sleeve to collapse.

Workaround: Use enclosed body design or reinforced sleeve

Sleeve Material Selection

The rubber sleeve should be given careful consideration because it is the only component that comes in contact with the media.

Key properties needed:

- Chemical compatibility

- Temperature resistance

- Abrasion resistance

- Flexibility/elasticity

- Pressure capability

Material guide:

Natural Rubber:

- Good general purpose

- Excellent elasticity

- Not for oils or chemicals

- -40°F to 180°F

NBR (Nitrile):

- Oil resistant

- Good chemical resistance

- Abrasion resistant

- -40°F to 200°F

EPDM:

- Excellent chemical resistance

- Steam compatible

- Ozone resistant

- -40°F to 250°F

Silicone:

- Wide temperature range

- Food grade available

- Poor abrasion resistance

- -60°F to 400°F

PTFE-lined:

- Extreme chemical resistance

- Nearly universal compatibility

- Higher cost

- -100°F to 400°F

Body Material

The valve body material should be lightweight for easy handling. The material does not need to be compatible with the media since they do not come in contact.

Common materials:

- Cast iron (economical)

- Ductile iron (stronger)

- Stainless steel (corrosive environments)

- Aluminum (lightweight)

- Plastic/PVC (lightweight, economical)

Sizing

For on/off applications:

- Valve size should match pipe size

- Avoids flow restriction

- No significant pressure drop

- Straightforward sizing

For throttling applications: The effective throttling range of a pinch valve is usually between 10% and 95% of the rated flow capacity.

Key points:

- Best flow control at last 50% of stroke

- Some designs have maximum opening at 50%

- Smooth walls don’t create significant drop until 50% closed

- Consider flow coefficient (Cv) requirements

Installation and Maintenance

Installation Guidelines

Typical installation:

- Valve can be installed in any orientation (horizontal, vertical, upside-down)

- Most are constructed so compression is from top only

- Allows thorough drainage in all positions except upside-down

- Ensure adequate support for valve weight

Connection types:

- Flanged (most common)

- Threaded

- Socket weld

- Grooved coupling

Air supply (for pneumatic):

- Clean, dry air required

- 80-120 PSI typical

- Install filter-regulator-lubricator (FRL) upstream

- Size air lines appropriately

Maintenance

Routine maintenance:

Daily/Weekly:

- Visual inspection of sleeve (if exposed)

- Check for leaks

- Verify operation

Monthly:

- Test operation

- Check air supply (pneumatic types)

- Inspect connections

Annually:

- Inspect sleeve for wear

- Check pinch mechanism alignment

- Lubricate mechanical parts (not sleeve)

Sleeve replacement:

- Expected life: 6 months to 5+ years (depends on application)

- Replacement typically takes 15-30 minutes

- Stockpile critical spare sleeves

- Simple procedure, minimal training needed

The term ‘fit and forget’ is often referred to when using Pinch Valves, because users can simply install the valve and then leave it alone to do it’s job without the need for any interference.

Comparison with Other Valves

Pinch Valve vs Ball Valve

Pinch Valve advantages:

- ✅ Better for abrasive media (no metal contact)

- ✅ Full bore when open

- ✅ Handles solids better

- ✅ Lower maintenance

Ball Valve advantages:

- ✅ Higher pressure ratings

- ✅ Better for clean fluids

- ✅ Faster actuation

- ✅ More compact

Pinch Valve vs Butterfly Valve

Pinch Valve advantages:

- ✅ No internal obstructions

- ✅ Better for slurries

- ✅ Self-cleaning

- ✅ Zero contamination

Butterfly Valve advantages:

- ✅ Lower cost (usually)

- ✅ More compact

- ✅ Lighter weight

- ✅ Better throttling control

Pinch Valve vs Diaphragm Valve

Pinch Valve advantages:

- ✅ Full bore (no restriction)

- ✅ Simpler design

- ✅ Lower cost

- ✅ Easier maintenance

Diaphragm Valve advantages:

- ✅ Better for precise throttling

- ✅ Higher pressure capability

- ✅ Better for gases

- ✅ More body materials available

Pinch Valve vs Knife Gate Valve

Pinch Valve advantages:

- ✅ Better sealing (especially with particles)

- ✅ No lubrication needed

- ✅ Self-cleaning action

- ✅ Simpler maintenance

Knife Gate Valve advantages:

- ✅ Higher pressure ratings

- ✅ Larger sizes available

- ✅ Can cut through solids

- ✅ Better for extremely thick slurries

Limitations and Considerations

When NOT to Use Pinch Valves

High pressure applications:

- Typical limit: 150 PSI

- Some designs to 250 PSI

- Not for high-pressure steam or gas

High temperature:

- Rubber sleeve limits temperature

- Typical maximum: 180-250°F

- Special materials to 400°F (PTFE)

Vacuum service:

- Sleeve tends to collapse

- Reinforced sleeves help but limited

- Consider diaphragm valves instead

Precise throttling:

- Not ideal for fine flow control

- Better for on/off or coarse throttling

- Diaphragm or globe valves better

Very large sizes:

- Typically available to 24″

- Larger sizes get impractical

- Knife gates or butterfly valves better

Clean, non-abrasive service:

- Pinch valves are “overkill”

- Ball or butterfly valves more economical

- Save pinch valves for difficult applications

Cost Considerations

Initial Cost

Factors affecting price:

- Size (larger = more expensive)

- Body material

- Sleeve material (PTFE most expensive)

- Actuation type (manual cheapest, pneumatic moderate)

- Brand and quality

Typical price ranges:

- 2-4″ manual: $200-600

- 2-4″ pneumatic: $400-1,200

- 6-12″ pneumatic: $1,000-4,000

- 12-24″ pneumatic: $3,000-10,000+

Total Cost of Ownership

Advantages:

- ✅ Low maintenance costs (simple design)

- ✅ Long sleeve life in proper applications

- ✅ No consumables (seals, packing)

- ✅ Less downtime

- ✅ Easy, fast sleeve replacement

Disadvantages:

- ❌ Sleeve replacement needed periodically

- ❌ Initial cost higher than some valves

- ❌ Spare sleeves inventory needed

ROI consideration: Many engineers have begun to switch to Pinch Valves because of their better overall performance. In many cases, pinch valves are used to replace other valves that constantly fail.

Frequently Asked Questions

What is the main advantage of a pinch valve?

The primary advantage is that only the rubber sleeve contacts the flowing media—all other valve parts remain isolated. This makes pinch valves ideal for abrasive, corrosive, or contamination-sensitive applications. The full bore design also prevents clogging with solids.

How long does a pinch valve sleeve last?

Sleeve life depends heavily on the application. In clean water service, sleeves can last 5+ years. In highly abrasive slurries, replacement may be needed every 6-12 months. Most industrial applications see 1-3 years of service. The predictable wear pattern allows planned maintenance.

Can pinch valves throttle flow?

Yes, but with limitations. Pinch valves can throttle effectively between 10-95% of flow capacity, with best control in the last 50% of the stroke. They’re better suited for on/off service or coarse throttling rather than precise flow control. For fine throttling, consider diaphragm or globe valves.

What is the maximum pressure rating?

Most pinch valves are rated for 150 PSI or less. Some heavy-duty designs can handle up to 250 PSI. The rubber sleeve limits pressure capability. For higher pressures, metal-seated valves like ball or gate valves are more appropriate.

Can pinch valves handle vacuum?

Standard pinch valves are not suitable for vacuum service—the sleeve tends to collapse inward when suction is applied. Reinforced sleeves or enclosed body designs can help, but vacuum capability is still limited. Diaphragm valves are generally better for vacuum applications.

Are pinch valves bidirectional?

Yes, pinch valves seal equally well with flow from either direction. There’s no preferred flow direction, making installation flexible. This is an advantage over check valves or many other valve types that must be installed directionally.

How do I select the right sleeve material?

Consider three factors: chemical compatibility with your media, operating temperature range, and abrasion resistance needed. For food applications, use FDA-approved materials. For acids/chemicals, EPDM or PTFE. For abrasive slurries, natural rubber or NBR. Consult material compatibility charts.

Can pinch valves be automated?

Yes, pneumatic pinch valves are easily automated with solenoid valves, positioners, or PLC control. They integrate well with automated processes. Manual pinch valves can be retrofitted with pneumatic or electric actuators. Response time is typically 1-2 seconds.

Conclusion

Pinch valves offer a simple, reliable solution for controlling difficult media like slurries, abrasives, and corrosives. Their unique design—with only a rubber sleeve contacting the process fluid—provides advantages that conventional valves cannot match.

Key benefits:

- ✅ Full bore, zero restriction

- ✅ Handles abrasive media without wear

- ✅ No contamination (food/pharma)

- ✅ Self-cleaning action

- ✅ Simple maintenance

- ✅ Cost-effective total ownership

Best applications:

- Slurries and abrasive materials

- Corrosive chemicals

- Food and pharmaceutical processing

- Wastewater and sludge handling

- Mining and mineral processing

When to choose pinch valves:

- Media is abrasive, corrosive, or viscous

- Contamination must be avoided

- Solids or particles in flow

- Low maintenance is priority

- Full bore flow is needed

When to choose something else:

- High pressure (>150 PSI)

- High temperature (>250°F)

- Vacuum service

- Precise throttling required

- Clean, non-abrasive media

For many difficult industrial applications, pinch valves are not just a good choice—they’re often the only valve that will provide reliable, long-term service. Their simplicity, durability, and unique operating principle make them an essential tool in modern industrial processes.