A pressure relief valve is an automatic safety device that opens to release excess pressure when it exceeds a safe limit, then closes once pressure returns to normal. Think of it as an emergency escape hatch for pressurized systems—when pressure builds dangerously high, the valve pops open to vent the excess before equipment explodes or ruptures.

Every water heater in your home has one. Every boiler, air compressor, and pressure vessel in industrial facilities has them. They’re the last line of defense against catastrophic failures that could destroy equipment, cause injuries, or even kill people. Yet most people never think about these critical safety devices until something goes wrong.

In this guide, we’ll explain what pressure relief valves are, why they’re essential, and how to recognize when yours needs attention.

Table of Contents

ToggleWhat Does a Pressure Relief Valve Look Like?

Before diving into technical details, let’s identify what you’re looking for:

On a Water Heater

Temperature & Pressure Relief Valve

│

▼

┌────────┐

│ Lever │ ← Test lever

├────────┤

│ [T&P] │ ← Brass body

│ 150 │ ← Pressure rating (PSI)

└───┬────┘

│

Discharge pipe → Goes to floor/drain

Location: Side or top of tank Appearance: Brass valve with lever, usually has a copper/PVC discharge pipe Size: Typically 3/4″ connection

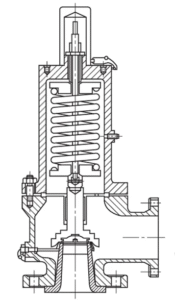

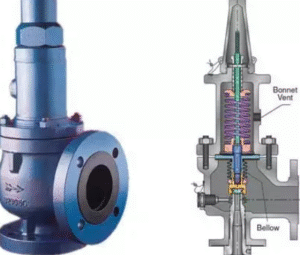

On Industrial Equipment

Appearance: Larger valve (2″-6″+) with:

- Spring-loaded bonnet on top

- Discharge outlet (side or top)

- Adjustment cap or locknut

- Nameplate with pressure rating

The Function of a Pressure Relief Valve

The function of pressure relief valve is simple but critical: prevent over-pressurization disasters.

What Happens Without a Relief Valve?

Imagine a closed tank being heated. As temperature rises, so does pressure. Without a relief valve:

- Pressure builds beyond design limits

- Metal weakens under stress

- Tank ruptures explosively

- Catastrophic failure occurs

Real-World Consequences

Without relief valves:

- Water heaters explode, destroying homes

- Boilers burst, injuring workers

- Pressure vessels fail, causing fires

- Hydraulic systems rupture, spraying hot oil

With relief valves:

- Excess pressure vents safely

- Equipment protected from damage

- People protected from injury

- Systems continue operating safely

This is why building codes, insurance companies, and safety regulations require pressure relief valves on virtually all pressurized equipment.

How Does a Pressure Relief Valve Work?

Understanding how relief valves work helps you recognize problems and maintain them properly.

The Basic Principle: Spring vs Pressure

NORMAL OPERATION (Valve Closed)

Spring Force DOWN

║║║

║║║

┌─┴─┐

│Disc│ ← Held closed by spring

════█████════

Sealed

System Pressure: 100 PSI

Spring Set Point: 150 PSI

Result: Valve CLOSED

OVER-PRESSURE (Valve Open)

Spring Force DOWN

╱╲╱

╱ ╲ ← Spring compressed

┌────┐

│Disc│ ← Lifted off seat

═══╪ ╪═══► Pressure venting

│ │

System Pressure: 155 PSI

Spring Set Point: 150 PSI

Result: Valve OPEN - Releasing pressure

Step-by-Step Operation

1. Normal Conditions (Closed)

- System operates below set pressure

- Spring holds disc firmly against seat

- No flow through valve

- Perfect seal maintained

2. Pressure Rises

- System pressure approaches set point

- Pressure force pushes against disc

- Spring resists opening

3. Set Pressure Reached (Opens)

- Pressure overcomes spring force

- Disc lifts off seat

- Fluid/gas escapes through outlet

- Pressure begins dropping

4. Pressure Drops (Closes)

- System pressure falls below set point

- Spring pushes disc back down

- Valve reseats and seals

- Normal operation resumes

Why This Matters

This automatic operation means:

- No human intervention needed

- Works even during power outages

- Responds in milliseconds

- Resets itself automatically

Pressure Relief Valve vs Pressure Reducing Valve

This confusion is so common it deserves its own section. People mix these up because both are called “PRV” and both deal with pressure—but they’re completely different devices.

The Critical Difference

| Feature | Pressure RELIEF Valve | Pressure REDUCING Valve |

|---|---|---|

| What it does | Opens ONLY during emergencies | Operates continuously |

| Normal state | Closed (no flow) | Open (always flowing) |

| When it works | When pressure is TOO HIGH | All the time (normal operation) |

| Purpose | Safety/protection | Pressure regulation |

| Location | On tanks, vessels, systems | On supply lines |

| Discharge | To atmosphere/drain | To downstream piping |

Simple Analogy

Pressure Relief Valve = Fire escape door

- Normally closed and locked

- Only opens during emergency

- Lets people escape danger

Pressure Reducing Valve = Thermostat

- Always working

- Continuously adjusting

- Maintains comfortable conditions

Why Confusion Is Dangerous

Installing a reducing valve where you need a relief valve provides zero safety protection. The reducing valve regulates normal pressure—it won’t protect against over-pressure emergencies.

Types of Relief Valves You Should Know

Different applications require different types of relief valves. Here are the main categories:

By Application

Safety Valve

- For: Steam, gas, compressible fluids

- Action: Pops fully open (fast)

- Common on: Boilers, steam systems

- Characteristic: Loud “pop” when opening

Relief Valve

- For: Liquids, incompressible fluids

- Action: Opens gradually (proportional)

- Common on: Water systems, hydraulic systems

- Characteristic: Smooth, gradual opening

Safety Relief Valve

- For: Either liquids or gases

- Design: Versatile, handles both

- Common on: Multi-purpose applications

- Characteristic: Certified for both service types

By Construction

| Type | Description | Best For |

|---|---|---|

| Direct acting | Spring directly opposes pressure | Most applications, simple systems |

| Pilot operated | Small pilot controls main valve | High capacity, precise control |

| Balanced | Compensates for back pressure | Variable discharge pressure |

Special Purpose Types

Temperature & Pressure (T&P) Relief Valve

- Responds to EITHER temperature OR pressure

- Standard on water heaters

- Opens at 150 PSI OR 210°F (whichever comes first)

Thermal Relief Valve

- Temperature-activated

- Protects blocked liquid lines

- Common in refrigeration

Vacuum Relief Valve

- Prevents negative pressure

- Protects tanks from collapse

- Common on storage tanks

Where Are Relief Valves Required?

Residential Applications

Water Heater (Required by code)

- T&P valve rated 150 PSI

- Discharge pipe to floor or drain

- Must be accessible for testing

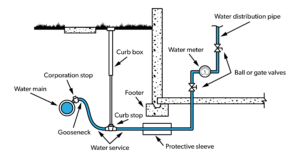

Well Pressure Tank

- Relief valve at tank

- Prevents over-pressurization if pressure switch fails

Pool/Spa Heater

- Relief valve on heat exchanger

- Protects against thermal expansion

Commercial/Industrial Applications

Boilers (Strictly regulated)

- ASME code required

- Sized based on boiler capacity

- Annual inspection required

Pressure Vessels

- All ASME vessels need relief protection

- Multiple valves on large vessels

- Certified capacity required

Hydraulic Systems

- Relief valve in every circuit

- Protects pumps and components

- Adjustable pressure setting

Compressed Air Systems

- Required on all air tanks

- Protects against compressor malfunction

- Often includes pressure gauge

Chemical Process Equipment

- Critical for safety

- Special materials for corrosive fluids

- Often piped to safe discharge location

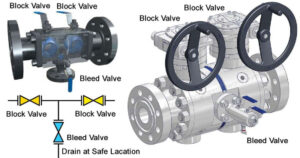

Relief Valve Symbols: Reading the Diagrams

Understanding pressure relief valve symbols helps you read system diagrams and P&IDs.

Basic Symbol

STANDARD RELIEF VALVE SYMBOL

─┬─ ← Connection to system

│╲

│ ╲ ← Triangle shows discharge direction

─┴──► ← Arrow points to relief/atmosphere

WITH SPRING INDICATOR

╱╲╱╲ ← Spring (adjustable set pressure)

││

─┬┼┬─

│╲│

│ ╲

─┴──►

COMPLETE P&ID SYMBOL

SET @ 150 PSI ← Annotation shows set pressure

│

╱╲╱╲╱╲

││││

─┬┼┬─

│╲│

│ ╲

─┴──► TO ATMOS

Symbol Variations

| Symbol Element | Meaning |

|---|---|

| Triangle pointing out | Discharge direction |

| Spring zigzag | Spring-loaded (adjustable) |

| Circle around valve | Indicates valve function |

| Horizontal line from symbol | Piped discharge |

| Open arrow end | Discharge to atmosphere |

Reading the Annotation

Typical label: “PRV-101, SET @ 150 PSIG”

- PRV = Pressure Relief Valve

- 101 = Tag number (for identification)

- 150 PSIG = Set pressure (gauge pressure)

How to Test Your Relief Valve

Regular testing ensures your relief valve will work when needed.

Water Heater T&P Valve Test

Frequency: Annually

Procedure:

- Place bucket under discharge pipe

- Lift test lever for 5 seconds

- Hot water should flow out

- Release lever—flow should stop

- If water continues dripping, valve needs replacement

Warning signs:

- No water flows when lever lifted

- Water continues flowing after release

- Valve is corroded or leaking

- Discharge pipe missing or improper

Industrial Relief Valve Testing

Professional testing required:

- Pop test (verify set pressure)

- Seat leakage test

- Capacity test (flow verification)

Testing frequency:

- Annual minimum (most codes)

- After any system over-pressure event

- When required by insurance

Common Relief Valve Problems

1. Continuous Leaking (Weeping)

Symptoms: Small, constant discharge

Causes:

- Set pressure too close to operating pressure

- Debris on seat preventing seal

- Worn or damaged seat

- Corrosion

Solutions:

- Reduce operating pressure

- Clean or replace valve

- Install pressure reducing valve upstream

2. Valve Won’t Open

Symptoms: Pressure exceeds set point, no discharge

Causes:

- Corroded disc stuck closed

- Wrong spring (too strong)

- Debris blocking mechanism

- Frozen valve (steam condensate)

Solutions:

- Replace valve immediately (safety hazard!)

- Never paint over relief valves

- Test regularly to prevent sticking

3. Valve Won’t Reseat

Symptoms: Continuous flow after opening

Causes:

- Damaged seat or disc

- Foreign material preventing seal

- Pressure surges during opening damaged components

Solutions:

- Replace valve

- Install strainer upstream

- Consider larger valve to reduce velocity damage

4. Chattering

Symptoms: Rapid opening/closing cycles

Causes:

- Oversized valve

- Excessive inlet pressure drop

- Vibration in system

Solutions:

- Properly size valve for application

- Install closer to protected equipment

- Add pilot-operated valve for better control

Pressure Relief Valve Maintenance

Inspection Checklist

Monthly visual inspection:

- [ ] No visible corrosion or damage

- [ ] Discharge pipe intact and properly routed

- [ ] No leaks from body or connections

- [ ] Tag/label readable with set pressure

Annual functional test:

- [ ] Manual lift test (where applicable)

- [ ] Verify operation and reseating

- [ ] Check for leaks after test

- [ ] Document test in maintenance log

5-Year maintenance:

- [ ] Disassemble and inspect internals

- [ ] Replace springs and seals

- [ ] Lap seats if necessary

- [ ] Recertify set pressure

When to Replace

Replace relief valve if:

- Failed annual test

- Visible corrosion or damage

- History of leaking/sticking

- Unknown service history

- Over 10 years old (preventive)

Never repair safety-critical components yourself unless properly trained and certified. Lives depend on these valves.

Function of Relief Valve in Hydraulic Systems

Hydraulic systems deserve special attention because relief valves serve additional purposes beyond basic safety.

Primary Functions in Hydraulic Systems

1. System Protection

- Limits maximum pressure to safe level

- Protects pumps from overpressure damage

- Prevents hose/fitting failures

2. Overload Protection

- Opens when load exceeds design limits

- Prevents equipment damage

- Acts as mechanical “fuse”

3. Circuit Control

- Can be used to sequence operations

- Provides secondary pressure control

- Enables pressure-compensated operation

Hydraulic Relief Valve Types

| Type | Function | Application |

|---|---|---|

| Direct acting | Simple overpressure protection | Small systems, simple machines |

| Pilot operated | Precise pressure control | Large systems, accurate pressure needed |

| Unloading | Dumps flow at low pressure | Energy saving during idle |

Common Settings

| Application | Typical Relief Setting |

|---|---|

| Mobile hydraulics | 2500-3000 PSI |

| Industrial hydraulics | 1000-1500 PSI |

| Servo systems | 3000-5000 PSI |

Always set 10-25% above normal operating pressure to avoid nuisance opening.

What to Do When Your Relief Valve Opens

If Your Water Heater Relief Valve Discharges

Immediate actions:

- Turn off heat source (gas/electric)

- Let water cool

- Check for cause (thermostat failure, high inlet pressure)

- Have professional inspect before restarting

Common causes:

- Thermostat stuck on

- Inlet pressure too high (need pressure reducing valve)

- Thermal expansion (need expansion tank)

If Industrial Relief Valve Opens

Emergency response:

- Identify which valve opened

- Isolate cause if possible

- Do NOT attempt to adjust or cap valve

- Allow pressure to normalize

- Investigate cause before restarting

- Document incident

Required follow-up:

- Inspect/test valve before returning to service

- Investigate root cause

- Consider if valve is properly sized

- File incident report if required

Conclusion

A pressure relief valve is your last line of defense against catastrophic over-pressure failures. These simple spring-loaded valves automatically open when pressure exceeds safe limits, venting excess pressure to atmosphere or a safe location—then automatically close when pressure returns to normal.

Key takeaways:

- Relief valves are safety devices, not operating controls

- They work automatically—no power or human intervention needed

- Not the same as pressure reducing valves (completely different purpose)

- Required by code on water heaters, boilers, pressure vessels, and many other systems

- Must be tested regularly and replaced when damaged or aged

- Never block, cap, or disable a relief valve—lives depend on them

Whether it’s the brass T&P valve on your water heater or the large industrial safety valve on a pressure vessel, these devices prevent explosions, save lives, and protect property. Respect them, maintain them, and they’ll reliably protect you for years.

Concerned about a relief valve on your equipment? Always consult a qualified professional for inspection, testing, or replacement of safety-critical components.