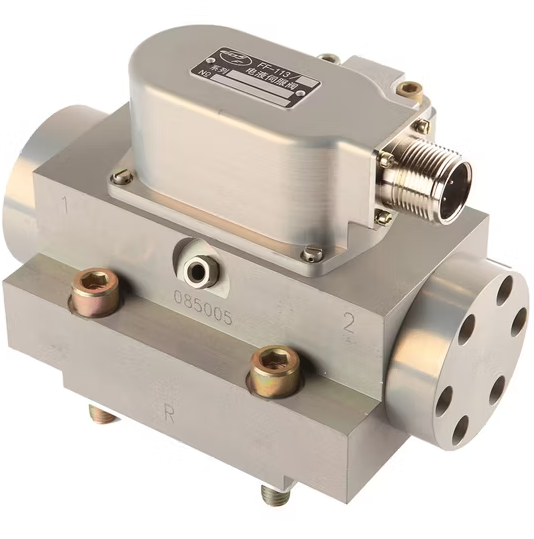

A servo valve is a high-precision, electro-hydraulic control valve used in systems that require accurate control of pressure, flow, and position. Unlike ordinary hydraulic valves that switch simply between open and closed states, a servo valve can continuously adjust the hydraulic output in response to an electrical input signal.

Because of their precision and fast response, servo valves are essential components in advanced hydraulic motion control systems.

Table of Contents

ToggleHow a Servo Valve Works

A servo valve converts an electrical command signal (usually from a controller or PLC) into a precise hydraulic action. The process typically involves three major stages:

Electrical Input Signal

The controller sends a voltage or current signal.

This signal represents a desired movement, pressure, or position.

Electro-Mechanical Conversion

An internal component (such as a torque motor or piezo actuator) converts the electrical signal into motion.

Hydraulic Adjustment

The motion adjusts a spool or flapper inside the valve.

This controls the amount of hydraulic fluid flowing to an actuator (e.g., a cylinder or hydraulic motor).

As a result, a servo valve allows smooth, accurate, and repeatable control of hydraulic equipment.

Key Features of Servo Valves

Servo valves are used in demanding applications because they offer:

✔ High Accuracy

They can precisely control fluid flow to achieve exact positioning and speed.

✔ Fast Response Time

Servo valves react very quickly to electrical signals, ideal for high-speed systems.

✔ Continuous Control

Unlike on/off valves, servo valves provide continuous and proportional control.

✔ Repeatability and Stability

They maintain performance even under varying loads.

Types of Servo Valves

Servo valves are generally classified into two main categories:

1. Nozzle–Flapper Servo Valve

Uses a flapper positioned between two nozzles.

A torque motor moves the flapper, creating a pressure difference.

Moves the spool to control flow.

Common and widely used.

2. Jet Pipe Servo Valve

Uses a jet of fluid directed toward receiver ports.

Offers greater contamination tolerance.

Often used in heavy-duty or industrial environments.

Some engineers also differentiate between single-stage, two-stage, and three-stage servo valves depending on their internal design.

Servo Valve vs. Proportional Valve

Although both are used for precise control, they are not the same:

| Feature | Servo Valve | Proportional Valve |

|---|---|---|

| Precision | Extremely high | Moderate |

| Response Speed | Very fast | Slower |

| Contamination Sensitivity | High | Lower |

| Cost | Higher | Lower |

| Applications | Aerospace, robotics, test benches | Industrial machinery, general hydraulics |

Servo valves are used for precision and speed, while proportional valves provide good control at lower cost.

Common Applications of Servo Valves

Servo valves are found in industries requiring exact motion, load control, or dynamic performance, including:

Aerospace (flight control systems)

Injection molding machines

Robotics and automation

Hydraulic presses

Metal forming and rolling mills

Test and simulation equipment

Turbine control systems

Defense and military hydraulic systems

Any application requiring fine control of hydraulic force or motion may use a servo valve.

Advantages of Servo Valves

Extremely precise motion control

Rapid response to command signals

Excellent repeatability

Capable of controlling position, velocity, and force

Ideal for dynamic or closed-loop systems

Disadvantages of Servo Valves

Higher cost compared to standard valves

Requires clean hydraulic oil (sensitive to contamination)

More complex and requires skilled maintenance

May need specialized electronics for control

Conclusion

A servo valve is a high-precision electro-hydraulic valve that provides accurate, fast, and continuous control of hydraulic fluid. It plays a critical role in advanced industrial systems where performance, responsiveness, and accuracy are essential.

Whether in aerospace, robotics, or heavy industrial machinery, servo valves enable controlled and reliable motion that standard hydraulic valves cannot achieve.