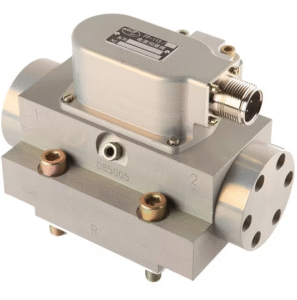

A solenoid valve is an electromechanically operated valve used to control the flow of liquids or gases automatically. It functions by using an electric current to generate a magnetic field that opens or closes the valve mechanism.

Solenoid valves are widely used in industrial automation, HVAC systems, water treatment, pneumatic and hydraulic systems, and process control — wherever precise and fast fluid control is required.

Table of Contents

ToggleHow Does a Solenoid Valve Work?

The basic working principle of a solenoid valve involves the interaction between an electric coil (solenoid) and a movable plunger (core).

When De-energized (No Power):

The plunger is held in position by a spring.

Depending on the design, the valve remains either closed (normally closed type) or open (normally open type).

When Energized (Power Applied):

Electric current flows through the solenoid coil, creating a magnetic field.

This magnetic force pulls or pushes the plunger, changing the valve position.

The movement opens or closes the flow path for the fluid or gas.

When power is removed, the spring returns the plunger to its original position, restoring the initial flow condition.

Main Components of a Solenoid Valve

A standard solenoid valve consists of the following key parts:

Solenoid Coil: Converts electrical energy into a magnetic field.

Plunger or Core: Moves under the influence of the magnetic field to open or close the valve.

Spring: Returns the plunger to its normal position when power is off.

Valve Body: Contains the fluid passage and the seat where sealing occurs.

Seal or Diaphragm: Ensures tight shut-off when the valve is closed.

Orifice: The passageway for fluid flow.

Types of Solenoid Valves

1. Based on Operation Mode

Normally Closed (NC):

The valve remains closed when de-energized and opens when current is applied.

Most commonly used for safety applications.Normally Open (NO):

The valve remains open when de-energized and closes when current is applied.

Used where continuous flow is preferred unless power is applied.Bi-Stable (Latching Type):

Uses a magnetic latch to maintain position even after power is removed.

Ideal for energy-saving applications.

2. Based on Design Structure

Direct Acting Solenoid Valve:

The plunger directly opens or closes the orifice.

Suitable for small flow rates and low-pressure systems.Pilot Operated (Indirect Acting) Solenoid Valve:

Uses line pressure to assist valve movement via a pilot orifice.

Suitable for large flow rates or high-pressure systems.Semi-Direct Acting Solenoid Valve:

Combines the benefits of both direct and pilot types — can operate at zero pressure differential.

Advantages of Solenoid Valves

✅ Fast and Precise Operation:

Instant response makes it ideal for automation systems.

✅ Remote and Automatic Control:

Easily controlled via electrical signals, sensors, or PLCs.

✅ Compact Design:

Small size with high functionality — easy to integrate in piping systems.

✅ Reliable and Durable:

Minimal moving parts ensure long life and low maintenance.

✅ Versatile Applications:

Available for water, air, steam, oil, gas, and chemical fluids.

Common Applications

Solenoid valves are used across a wide range of industries, including:

Water Supply & Irrigation Systems – automatic flow control and shut-off

HVAC Systems – refrigerant and air control

Industrial Automation – controlling pneumatic or hydraulic cylinders

Oil & Gas – precise control of fuel and process gases

Food & Beverage Industry – clean, hygienic control of fluids

Medical Equipment – oxygen and anesthesia flow regulation

Fire Protection Systems – controlling sprinkler or foam flow

Selection Guide

When choosing a solenoid valve, consider the following parameters:

| Parameter | Consideration |

|---|---|

| Medium Type | Water, air, oil, gas, chemical, or steam |

| Operation Type | Normally closed, normally open, or latching |

| Pressure Range | Working and differential pressure |

| Temperature | Compatible with fluid and ambient conditions |

| Voltage | Commonly DC 12V/24V or AC 110V/220V |

| Material | Brass, stainless steel, PVC, or PTFE |

| Connection | Threaded, flanged, or manifold-mounted |

Maintenance Tips

Clean the valve and orifice regularly to avoid clogging.

Check coil resistance periodically to ensure proper operation.

Inspect seals for wear and replace if leakage occurs.

Avoid prolonged coil energization beyond rated time.

Use filters upstream to prevent debris entry.

Conclusion

A solenoid valve is a key component for automatic fluid control, providing fast, precise, and reliable operation across multiple industries.

Its electromagnetic actuation allows seamless integration with automation systems, enabling users to control water, air, or gas flow with just an electrical signal.

For industrial-grade performance and long service life, TOT Solenoid Valves are engineered with high-quality materials, international certifications, and customizable specifications — ensuring safe, efficient, and automated control for your systems.