Table of Contents

ToggleQuick Answer

A steam trap is an automatic valve that removes condensate (liquid water), air, and other non-condensable gases from steam systems while preventing live steam from escaping. It acts like a smart gatekeeper—letting unwanted water and air out, but keeping valuable steam in.

Key purpose: Maximize energy efficiency by removing water while retaining heat energy in the steam system.

What Is a Steam Trap?

Simple Explanation

Think of a steam trap as a selective door in your steam system. When steam does its job of heating something, it cools down and turns back into water (condensate). The steam trap automatically:

- ✅ Opens to let condensate (water) drain out

- ✅ Opens to let air escape during startup

- ✅ Closes to prevent steam from escaping

- ✅ Does this all automatically without electricity

The Problem Steam Traps Solve

Without steam traps:

- Condensate accumulates in pipes and equipment

- Water reduces heating efficiency (steam is 6x better than hot water)

- Water hammer can damage pipes and equipment

- Equipment corrodes faster

- Energy is wasted

With steam traps:

- Condensate removed immediately

- Maximum heat transfer maintained

- Equipment protected from damage

- Energy savings of 10-30%

- Extended equipment life

Real-World Analogy

A steam trap is like an automatic drain plug in your bathtub that:

- Lets water out when the tub is too full

- Keeps the stopper closed when you want to keep water in

- Works automatically without you having to do anything

- Never lets air bubbles stay trapped

How Do Steam Traps Work?

Basic Operating Principle

All steam traps distinguish between steam and condensate using one of three physical properties:

- Temperature difference (steam is hotter than condensate)

- Density difference (condensate is denser than steam)

- Phase change (steam vs. liquid)

The trap uses these differences to operate a valve mechanism automatically.

The Three Main Mechanisms

1. Thermostatic (Temperature-Based)

Cool condensate → Valve opens → Condensate drains

Hot steam arrives → Valve closes → Steam retained

2. Mechanical (Density-Based)

Dense condensate → Float rises/falls → Valve opens → Condensate drains

Light steam → Float position changes → Valve closes

3. Thermodynamic (Phase Change)

High-velocity condensate → Creates pressure drop → Disc lifts → Condensate drains

Steam flash → Increases pressure → Disc closes → Steam retained

Why It’s Called a “Trap”

The term “trap” comes from plumbing—like a drain trap under your sink that traps sewer gases while letting water through. A steam trap similarly “traps” steam while letting condensate pass.

Types of Steam Traps

1. Thermostatic Steam Traps

How they work: Use temperature-sensitive element that contracts when condensate cools, opening the valve.

Types:

Balanced Pressure Thermostatic (BPT)

- Bellows or capsule filled with liquid with boiling point below water

- Element contracts when cool condensate present

- Opens wide to discharge condensate and air

- Closes when steam arrives

Advantages:

- ✅ Excellent air venting capability

- ✅ Compact size

- ✅ Resistant to water hammer

- ✅ Good for low-pressure systems

- ✅ Inexpensive ($50-200)

Disadvantages:

- ❌ Can’t handle large condensate loads

- ❌ Element can fail in high-pressure systems

- ❌ Discharge temperature must be below steam temperature

Best applications:

- Tracer lines

- Air heating coils

- Low-capacity drip applications

- Terminal equipment

Bimetallic Steam Traps

- Two metal strips with different expansion rates

- Bends with temperature changes

- Opens valve when cool

Advantages:

- ✅ Durable construction

- ✅ No moving parts to wear

- ✅ Handles high pressures

- ✅ Low cost

Disadvantages:

- ❌ Slow response time

- ❌ Can freeze in cold climates

- ❌ May discharge some live steam

Best applications:

- Light load drip service

- Lower-pressure steam systems

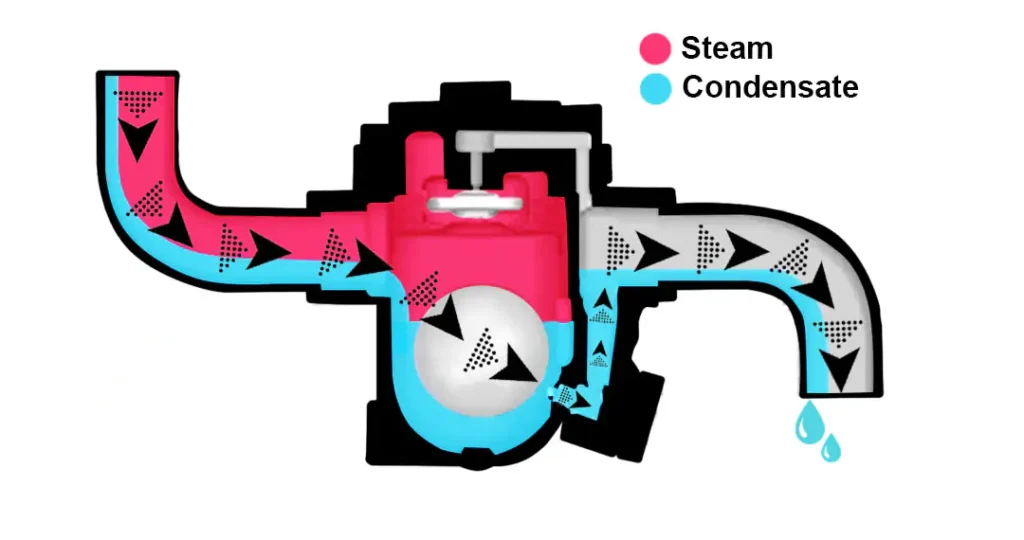

2. Mechanical Steam Traps

How they work: Use the density difference between condensate (heavy) and steam (light) to operate a float or bucket mechanism.

Types:

Float and Thermostatic (F&T)

- Ball float rises with condensate level

- Opens valve continuously as condensate enters

- Built-in thermostatic air vent

- Can modulate valve opening

Advantages:

- ✅ Continuous condensate discharge (most efficient)

- ✅ Handles large, variable loads

- ✅ Maximum heat transfer

- ✅ Excellent for process applications

- ✅ Long service life

Disadvantages:

- ❌ More expensive ($300-1,500)

- ❌ Can’t handle superheat above 25°F

- ❌ Subject to water hammer damage

- ❌ Must be installed level

Best applications:

- Process heating (heat exchangers, dryers, autoclaves)

- High-capacity drainage

- Main steam line drips

- Applications requiring continuous discharge

Inverted Bucket

- Upside-down bucket floats in condensate

- Steam enters bucket, making it buoyant

- Bucket rises, closing valve

- Condensate fills bucket, sinking it and opening valve

Advantages:

- ✅ Simple, rugged design

- ✅ Handles dirt and scale well

- ✅ Vents air and CO2 continuously

- ✅ Resistant to water hammer

- ✅ Works in any orientation

Disadvantages:

- ❌ Intermittent discharge (can cause temperature swings)

- ❌ Loses water seal on startup (needs priming)

- ❌ Not suitable for low-pressure systems (<5 PSI)

Best applications:

- Medium to high-pressure systems

- Dirty or harsh conditions

- Main drip lines

- General purpose use

Open Bucket/Float Traps (Older Design)

- Rarely used today

- Replaced by inverted bucket

3. Thermodynamic Steam Traps

How they work: Use the thermodynamic principle that hot condensate flashes to steam when pressure drops, creating pressure changes that operate a disc.

Mechanism:

1. Condensate enters under disc

2. High velocity creates low pressure (Bernoulli effect)

3. Disc lifts, allowing condensate to discharge

4. Flash steam forms in upper chamber

5. Pressure above disc increases, pushing disc closed

6. Cycle repeats

Advantages:

- ✅ Compact and lightweight

- ✅ Simple design (one moving part)

- ✅ Handles high pressures and temperatures

- ✅ Resistant to water hammer and freezing

- ✅ Works in any orientation

- ✅ Handles superheat well

- ✅ Low cost ($75-250)

Disadvantages:

- ❌ Noisy operation (cycling sound)

- ❌ Can lose efficiency over time (disc wear)

- ❌ Poor air venting (needs separate air vent)

- ❌ Not suitable for very low pressures (<15 PSI)

- ❌ Can pass live steam intermittently

Best applications:

- High-pressure steam mains

- Superheat applications

- Outdoor installations (freeze-resistant)

- Tracer lines

- General drip service

Steam Trap Comparison Table

| Feature | Thermostatic | Mechanical F&T | Inverted Bucket | Thermodynamic |

|---|---|---|---|---|

| Discharge | Intermittent | Continuous | Intermittent | Intermittent |

| Air venting | Excellent | Good (built-in) | Continuous | Poor |

| Dirt tolerance | Good | Fair | Excellent | Good |

| Water hammer | Excellent | Poor | Excellent | Excellent |

| Size | Compact | Large | Medium | Very compact |

| Cost | Low | High | Medium | Low-Medium |

| Pressure range | Low-Medium | All | Medium-High | Medium-High |

| Best for | Light loads | Heavy loads | General purpose | High pressure |

What Is a Steam Trap Used For?

Primary Functions

1. Condensate Removal Steam traps remove condensate from steam systems as quickly as it forms, preventing waterlogging that reduces efficiency.

Why it matters:

- Condensate has only 20% the heat capacity of steam

- Water accumulation creates cold spots

- Equipment performance drops dramatically

2. Air and Gas Removal Steam traps remove air and non-condensable gases from the steam space during system startup and operation.

Why it matters:

- Air is an insulator (reduces heat transfer by up to 50%)

- CO2 in air forms carbonic acid (causes corrosion)

- Air pockets prevent steam from reaching equipment

3. Steam Conservation Steam traps prevent loss of live steam to the condensate return system or atmosphere.

Why it matters:

- Lost steam = wasted fuel

- A single failed-open trap can waste $10,000+ annually

- Steam is expensive to produce

Common Applications

Industrial Process Equipment:

- Heat exchangers

- Dryers and autoclaves

- Jacketed vessels and tanks

- Vulcanizers

- Presses and platens

- Melting pots

Steam Distribution Systems:

- Main steam headers

- Branch lines

- Drip legs and drip pockets

- Separator stations

- Terminal equipment

HVAC Systems:

- Unit heaters

- Radiators

- Fan coil units

- Air handling units

- Finned tube radiation

Other Applications:

- Steam tracer lines

- Tire vulcanizing

- Cooking equipment

- Sterilizers

- Industrial laundry

Steam Trap Installation

Basic Installation Requirements

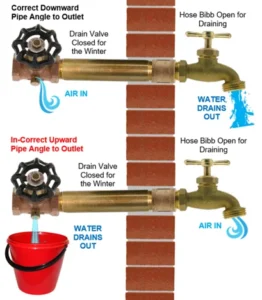

1. Location

- Install at low points where condensate collects

- As close to equipment as practical

- Accessible for maintenance

2. Orientation

- Most traps must be installed upright

- Check manufacturer specifications

- Thermodynamic traps work in any position

3. Piping Arrangement

Standard installation includes:

Equipment → Strainer → Isolation Valve → Steam Trap → Check Valve → Return Line

Essential components:

Strainer (upstream):

- Removes dirt and scale

- Protects trap internals

- 40-60 mesh recommended

- Install horizontal with screen down

Isolation valves (both sides):

- Allow trap removal without system shutdown

- Ball valves preferred for tight shutoff

Check valve (downstream):

- Prevents backflow into trap

- Critical if return line pressure varies

- Install after trap with arrow pointing away

Test valve or sight glass:

- Verify trap operation

- Check condensate discharge

- Helps diagnose problems

Drip Leg Sizing

For steam mains, proper drip leg design is critical:

Minimum sizing:

- Drip leg pipe diameter = Main line diameter

- Drip leg length = 24-36 inches minimum

- Provides storage for condensate during load changes

Location:

- Every low point

- Ahead of control valves and regulating stations

- Before risers

- At end of mains

- Every 300-500 feet on horizontal runs

Installation Mistakes to Avoid

❌ Mistake 1: Undersized drip leg

- Creates condensate backup

- Causes water hammer

- Reduces trap effectiveness

❌ Mistake 2: No strainer

- Dirt damages trap internals

- Shortened trap life

- Frequent failures

❌ Mistake 3: Incorrect orientation

- Trap won’t function properly

- Possible damage

- Steam loss

❌ Mistake 4: Inadequate drainage

- Condensate backup into equipment

- Reduced efficiency

- Possible water hammer

❌ Mistake 5: Wrong trap type for application

- Poor performance

- Energy waste

- Premature failure

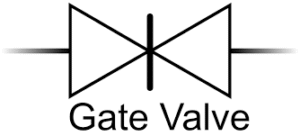

Steam Trap Symbols and P&ID Representation

Standard P&ID Symbols

Generic Steam Trap:

───┤├───

▼

With detail showing direction:

Equipment → [▼] → Return

Thermodynamic Trap:

───[TD]───

▼

Float & Thermostatic Trap:

───[F&T]───

▼

Inverted Bucket Trap:

───[IB]───

▼

Complete Assembly Symbol

Typical P&ID representation with accessories:

Steam Line ─── Y ─── ─●─ ─── [TRAP] ─── ─✓─ ─── Return Line

│ │ │

Strainer Isolation Check Valve

Valves

Where:

- Y = Strainer

- ─●─ = Isolation valve (ball valve)

- [TRAP] = Steam trap (type specified)

- ─✓─ = Check valve

Symbol Variations by Standard

ISA (Instrument Society of America):

- Shows trap with type designation (TD, F&T, IB, BPT)

- Arrow indicates flow direction

- Includes tag number

Industry practice:

- Labels specify trap type, size, and pressure rating

- Example: “ST-101 | 3/4″ TD | 150# | TOS”

- TOS = Top of Steel (elevation reference)

How to Select the Right Steam Trap

Key Selection Criteria

1. Operating Pressure

- Trap must handle maximum system pressure

- Include safety margin (25% recommended)

- Consider pressure differentials

2. Condensate Load

- Calculate maximum condensate generation rate

- Factor in startup vs. running loads

- Include safety factor (2-3× for startup)

3. Application Type

- Drip service (intermittent)

- Process equipment (continuous)

- Tracer line (light load)

- Main line (variable load)

4. Back Pressure

- Return line pressure affects trap performance

- Must have adequate differential pressure

- Minimum 10% differential recommended

5. Superheat Tolerance

- Can trap handle superheated steam?

- Thermodynamic traps best for superheat

- F&T traps limited to 25°F superheat

6. Air Venting Requirements

- Thermostatic traps excel at air removal

- Thermodynamic traps need separate air vents

- Critical for system startup

Selection Quick Guide

For process equipment (heat exchangers, dryers): → Float & Thermostatic (F&T)

- Continuous discharge maximizes heat transfer

- Handles variable loads

- Best for production equipment

For steam main drip service: → Inverted Bucket or Thermodynamic

- Handles dirt well

- Rugged construction

- Good for variable pressures

For tracer lines: → Thermostatic or Thermodynamic

- Compact size

- Light condensate load

- Easy installation

For high-pressure applications: → Thermodynamic

- Handles high pressures and temperatures

- Tolerates superheat

- Simple, rugged design

For low-pressure systems (<15 PSI): → Thermostatic (BPT)

- Works at very low differentials

- Excellent air venting

- Economical

Sizing Considerations

Calculate condensate load:

For heating equipment:

Condensate load (lb/hr) = BTU required / Latent heat of steam

Example:

Heat load: 500,000 BTU/hr

Steam at 100 PSI: Latent heat = 889 BTU/lb

Condensate load = 500,000 / 889 = 562 lb/hr

Apply safety factor:

- Running load × 2 = Minimum trap capacity

- Running load × 3 = Recommended for startup

- Use trap manufacturer’s capacity tables

Consider differential pressure:

- More differential = smaller trap needed

- Less differential = larger trap needed

- Check capacity at actual operating conditions

Troubleshooting Steam Traps

How to Test Steam Traps

1. Visual Inspection

- Look for steam plumes (indicates blow-through)

- Check for leaks at connections

- Inspect for physical damage

2. Temperature Testing

- Use infrared thermometer or temp gun

- Measure inlet and outlet temperatures

Failed open: Outlet very hot (near steam temp) Failed closed: Inlet very hot, outlet cold Normal: Outlet warm but cooler than inlet

3. Sound Testing

- Use ultrasonic detector or listen with screwdriver

- Learn normal sound patterns

Thermodynamic trap: Regular clicking (cycling) Inverted bucket: Intermittent discharge sounds F&T trap: Continuous quiet flow Failed open: Constant hissing

4. Sight Glass Testing

- Install sight glass in discharge line

- Observe discharge pattern

Normal: Clear condensate discharge Failed open: Continuous steam (white plume) Failed closed: No discharge visible

Common Problems and Solutions

Problem 1: Steam Blowing Through (Failed Open)

Symptoms:

- Continuous steam plume from discharge

- Very hot outlet temperature

- Loud hissing noise

- High energy waste

Causes: □ Worn valve seat or disc □ Dirt holding valve open □ Internal component failure □ Wrong trap type for application

Solutions:

- Clean strainer upstream

- Check for dirt in trap body

- Replace internal parts if available

- Replace entire trap if beyond repair

- Verify correct trap selection

Problem 2: Trap Not Discharging (Failed Closed)

Symptoms:

- No discharge visible

- Cold outlet temperature

- Equipment waterlogged

- Poor heating performance

Causes: □ Plugged trap or strainer □ Frozen trap (cold weather) □ Loss of prime (inverted bucket) □ Insufficient pressure differential

Solutions:

- Clean or replace strainer

- Insulate trap and discharge line

- Prime inverted bucket traps

- Check return line back pressure

- Verify adequate differential pressure

Problem 3: Intermittent Operation

Symptoms:

- Works sometimes, not others

- Temperature swings at equipment

- Cycling too fast or too slow

Causes: □ Dirt in trap causing sticking □ Worn parts causing poor sealing □ Insufficient condensate supply □ Oversized trap

Solutions:

- Clean trap and strainer

- Replace worn components

- Check condensate load calculations

- Resize trap if necessary

Problem 4: Noisy Operation

Symptoms:

- Loud banging (water hammer)

- Constant hissing

- Clicking or rattling

Causes: □ Water hammer from wet steam □ Failed open trap □ Loose internal parts □ Normal operation (thermodynamic cycling)

Solutions:

- Install drip legs properly

- Replace failed-open traps

- Check internal components

- Verify if noise is normal for trap type

Problem 5: Rapid Cycling

Symptoms:

- Trap opens and closes very frequently

- Temperature fluctuations

- Reduced equipment performance

Causes: □ Trap undersized for load □ Insufficient drip leg capacity □ Back pressure too high □ Wrong trap type

Solutions:

- Upsize trap to handle load

- Increase drip leg size

- Check return system pressure

- Consider different trap type

Maintenance Schedule

Monthly:

- Visual inspection for leaks

- Check for steam plumes

- Listen for unusual sounds

Quarterly:

- Test with temperature or ultrasound

- Clean strainers

- Check valve operation

Annually:

- Complete trap survey

- Rebuild or replace as needed

- Update trap inventory

- Calculate savings from repairs

As needed:

- Replace failed traps immediately

- A single failed-open trap can waste thousands of dollars annually

Energy and Cost Considerations

Cost of Failed Steam Traps

Failed-open trap losses:

Example calculation:

- Trap orifice: 1/4″ diameter

- Steam pressure: 100 PSI

- Cost of steam: $10 per 1,000 lbs

Steam loss: ~225 lb/hr through 1/4″ orifice Annual loss: 225 × 24 × 365 = 1,971,000 lb/year Annual cost: 1,971 × $10 = $19,710

For a single failed trap!

Energy Savings from Proper Trap Management

Typical savings from trap survey and repair:

- 10-30% reduction in steam consumption

- Payback period: 6-18 months

- Ongoing annual savings

- Improved product quality

- Extended equipment life

Best practices:

- Regular trap testing (quarterly to annually)

- Immediate repair of failed traps

- Proper trap selection and sizing

- Good installation practices

- Maintain trap inventory and records

Safety Considerations

Installation Safety

⚠️ High Temperature and Pressure:

- Steam systems operate at temperatures above 212°F

- Pressures can exceed 150 PSI

- Wear appropriate PPE (gloves, face shield)

- Depressurize before maintenance

⚠️ Hot Condensate:

- Condensate at pressure is above 212°F

- Can flash to steam when released

- Use caution opening drain valves

- Allow system to cool before opening

⚠️ Working on Live Steam:

- Never attempt trap replacement on pressurized system

- Use isolation valves

- Verify zero energy state

- Lock out/tag out procedures

Operational Safety

Pressure Relief:

- All trapped sections need pressure relief

- Install safety valves where required

- Never block or plug relief devices

Thermal Expansion:

- Allow for pipe expansion/contraction

- Use proper pipe supports

- Install expansion loops if needed

Water Hammer Prevention:

- Proper drip leg installation

- Correct trap sizing

- Adequate condensate drainage

- Avoid undersized return lines

Frequently Asked Questions

How long do steam traps last?

Trap life varies by type and conditions:

- Thermodynamic: 3-10 years

- Inverted Bucket: 5-15 years

- Float & Thermostatic: 10-20 years

- Thermostatic: 5-10 years

Factors affecting lifespan: operating pressure, condensate load, water quality, maintenance practices.

Can I install a steam trap backwards?

No. Steam traps are directional and must be installed with flow in the correct direction. Arrow on body indicates flow direction. Installing backwards will cause trap failure and steam loss.

Do steam traps need electricity?

No. All steam traps are self-powered by the pressure differential between steam and condensate. They operate mechanically without external power.

Why do steam traps fail?

Common causes:

- Dirt and scale buildup

- Worn valve seats

- Corrosion

- Water hammer damage

- Incorrect sizing or selection

- Poor installation

- Normal wear over time

Regular maintenance and testing minimize failures.

Can one steam trap serve multiple pieces of equipment?

Generally no. Each piece of equipment should have its own trap to ensure proper drainage and optimal performance. Combining loads can cause waterlogging and reduced efficiency.

Exception: Multiple small identical units very close together may share a trap if properly sized.

What size steam trap do I need?

Sizing requires:

- Calculate maximum condensate load

- Determine operating pressure and back pressure

- Apply safety factor (2-3× for startup)

- Check manufacturer’s capacity tables

- Select trap with adequate capacity at actual conditions

Never simply match trap size to pipe size—this often results in oversized traps.

Should I repair or replace a failed steam trap?

Replace if:

- Cost of repair exceeds 50% of new trap cost

- Trap is old (over 10-15 years)

- Body is corroded or damaged

- Repeated failures occur

Repair if:

- Simple cleaning resolves issue

- Replacement parts readily available

- Trap is relatively new

- Quality trap worth rebuilding

Many modern traps are designed as throw-away units with non-serviceable internals.

Conclusion

Steam traps are essential but often overlooked components in steam systems. They perform the critical function of removing condensate and air while preventing steam loss—directly impacting energy efficiency, equipment performance, and operating costs.

Key takeaways:

Understanding:

- ✅ Steam traps are automatic valves removing water and air

- ✅ Three main types: thermostatic, mechanical, thermodynamic

- ✅ Each type suited for specific applications

Selection:

- ✅ Match trap type to application requirements

- ✅ Size for condensate load with safety factor

- ✅ Consider pressure, temperature, and back pressure

Installation:

- ✅ Follow proper piping arrangements

- ✅ Include strainers, isolation valves, check valves

- ✅ Install at correct orientation and location

Maintenance:

- ✅ Test traps regularly (quarterly to annually)

- ✅ Repair or replace failed traps immediately

- ✅ A single failed trap can waste $10,000+ per year

- ✅ Proper maintenance pays for itself quickly

For industrial and commercial steam systems, implementing a comprehensive steam trap management program delivers substantial energy savings, improved reliability, and extended equipment life. When in doubt, consult with us for specific application guidance.