The question, “What is a stop valve?” addresses one of the most fundamental and vital components in any fluid control system. A stop valve is, in essence, a mechanical device designed to stop, isolate, or regulate the flow of fluid (whether liquid, gas, or slurry) within a pipeline. Serving as a deliberate barrier, its ability to completely halt flow allows for crucial safety, maintenance, and operational control across all sectors, from residential plumbing to large-scale industrial plants.

Understanding the function and various types of stop valves is key to designing safe and efficient fluid systems.

Table of Contents

ToggleThe Core Function and Mechanism of a Stop Valve

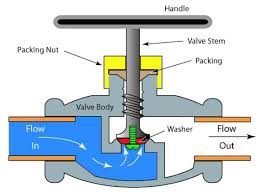

Every stop valve operates based on a similar principle: a closure element moves into the path of the fluid to create a seal against a stationary component called a seat. The effectiveness of the stop valve relies on the integrity of this seal.

Primary Roles of the Stop Valve:

Isolation (Shut-off): The most common role. A stop valve provides a quick and absolute shut-off, allowing sections of piping or equipment to be isolated for repairs, replacement, or inspection without affecting the rest of the system.

Emergency Control: In case of sudden leaks or failures, an easily accessible stop valve can be closed immediately to prevent damage or hazardous conditions.

Flow Regulation (Throttling): While some types are strictly for on/off service, others, like the globe valve, are explicitly designed as stop valves that can precisely regulate (throttle) the flow rate.

The closure mechanism is what differentiates the various types of stop valves used in engineering applications.

🔍 Exploring Common Types of Stop Valves

While the term is broad, three primary valve designs are most commonly referred to as stop valves due to their critical shut-off capabilities:

1. Globe Valves: The Throttling Stop Valve

Design: Characterized by a body where the flow path changes direction, forcing the fluid through an opening controlled by a moving disc.

Key Advantage: Excellent capability for both stopping flow and precise flow regulation (throttling).

Application: Ideal for services that require frequent flow adjustments, such as controlling cooling water, fuel oil, and steam flow.

2. Gate Valves: The Full-Flow Stop Valve

Design: Utilizes a flat, wedge-shaped gate that is raised or lowered perpendicular to the flow. When fully open, the gate is entirely out of the flow path.

Key Advantage: Provides a full, unobstructed flow when open, resulting in very low-pressure drop.

Application: Best used for on/off stop valve service where the valve is rarely operated and maximum flow capacity is needed, such as main water supply lines.

3. Ball Valves: The Quarter-Turn Stop Valve

Design: Employs a spherical ball with a hole through the center. A quarter-turn ($90^\circ$) rotates the bore either in line with the pipe (open) or perpendicular to it (closed).

Key Advantage: Offers fast, tight shut-off and simple operation. They are highly reliable for stopping flow completely.

Application: Extremely common in household plumbing, gas distribution, and industrial process systems due to their durability and ease of use.

💡 Expert Guidance: When and Where to Use a Stop Valve

Selecting the correct stop valve requires an engineering perspective that goes beyond simply asking what is a stop valve. It involves matching the valve’s capabilities to the system’s needs:

| Application Environment | Primary Requirement | Recommended Stop Valve Type | Reason |

| Household Faucet Isolation | Quick, reliable isolation | Ball Valve | Fast operation, tight shut-off, compact size. |

| Main Utility Line (Water/Gas) | Unobstructed flow, infrequent use | Gate Valve or Ball Valve | Minimal pressure drop when open; reliable isolation. |

| Steam/Process Control | Frequent, precise flow adjustment | Globe Valve | Designed for throttling and flow stability. |

| Corrosive Chemicals | Isolation, minimal internal erosion | Ball or specialty plug valves | Body and trim materials can be adapted to chemical service. |

The simple act of incorporating the right stop valve at critical points is what transforms a simple piping network into a manageable, safe, and maintainable fluid system.