In municipal water works and industrial piping, shut-offs are often not an option. Hospitals, large residential complexes, and manufacturing plants require constant fluid supply. So, how do you add a new branch to a pressurized pipeline without turning off the water?

The answer lies in a specialized engineering solution: the Tapping Valve and its partner, the Tapping Sleeve. In the industry, this assembly is commonly known as TS&V.

Table of Contents

Toggle1. Direct Answer: What is a Tapping Valve?

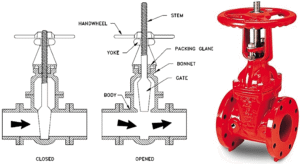

A tapping valve is a specialized gate valve designed to facilitate “Wet Tapping” (also known as Hot Tapping). It allows you to create a new branch connection to an existing “live” pipeline while it remains under full pressure and in service.

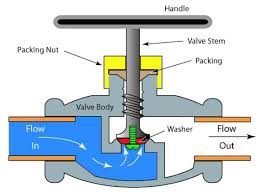

Unlike a standard gate valve, a tapping valve features an oversized seat opening (Full Bore). This design ensures that the cutting tool of a tapping machine can pass through the valve body to drill into the main pipe without damaging the valve’s internal sealing mechanism.

2. TS&V Explained: The Industry Gold Sta

The Tapping Sleeve: A high-strength metal “clamp” or “saddle” that wraps around the existing main pipe to provide a secure, leak-proof mounting point.

The Tapping Valve: The control gate that bolts onto the sleeve, providing the gateway for the drill and the future shut-off point for the new branch.

Together, the tapping sleeve and valve form a permanent, reinforced tee-connection that is as strong—if not stronger—than the original pipe.

3. How It Works: The Wet Tapping Process

Understanding how a tap with valve assembly works is key to a successful installation. The process follows these four main steps:

Installation: The tapping sleeve is bolted onto the water main, and the tapping valve is attached to the sleeve’s flange.

Pressure Test: The assembly is pressure-tested to ensure there are zero leaks before any cutting begins.

The Cut: A tapping machine is attached to the open valve. The machine’s cutter extends through the open valve, drills a hole in the main pipe, and retracts, bringing the “coupon” (the piece of pipe cut out) with it.

Activation: The tapping valve is closed, the machine is removed, and the new lateral line is connected. The valve is then opened to start the flow.

4. Primary Application: The Water Main Tapping Sleeve

The most common application for this technology is in Water Main systems. Engineers specify a water main tapping sleeve when:

Adding fire hydrants to an existing line.

Connecting new commercial developments to the city water supply.

Expanding industrial cooling loops without a plant shutdown.

For these applications, material choice is critical. Most tapping connection systems utilize Ductile Iron or Stainless Steel for the sleeve and WCB (Cast Steel) or Ductile Iron for the valve body to ensure a service life of 50+ years.

Conclusion: Reliability Under Pressure

A tapping valve is more than just a gate; it is a critical piece of infrastructure that saves thousands of dollars in downtime and prevents community-wide service interruptions.